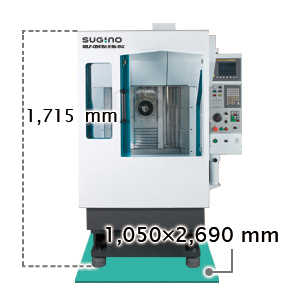

Self-Center H15B-5AX: #30 5-axis Control Horizontal Type Compact Machining Center

Horizontal type,compact and 5-axis control !

With a machine width of 1,050 mm, this machining equipment features a space-saving design, and yet is highly rigid and capable of simultaneous 5-axis control.

Its horizontal design ensures that chips are discharged with high efficiency.

It also features a column traverse design that provides flexible support for automating production lines.Furthermore, it employs a highly rigid spindle, which makes it ideal for machining titanium, a difficult-to-machine material.

Basic Specifications

Horizontal #30

Horizontal #30

X: 200 mm, Y: 200 mm, Z: 200 mm

A ±110° C 360°

Number of tools mounted

15 tools

* Optional 29 tools

Maximum spindle

Maximum spindle

rotation speed

20,000 min-1

2.2 kW

* Supported options

Machining capacity

Aluminum φ20 mm

Cast iron φ18 mm

Steel φ 14 mm

Aluminum M20 mm

Cast iron M14 mm

Steel M12 mm

Aluminum 150 cm

Cast iron 50 cm

Steel 25 cm

Features of the H15B

1. Space-saving and Energy-saving Design

With a footprint of just 2.8 m2, the machine has been designed to be more compact than its predecessor while maintaining an adequate machining area. Its width and height have been minimized to save the operator from the trouble of moving more than necessary even when multiple machines are installed, thus leading to higher productivity.

With a footprint of just 2.8 m2, the machine has been designed to be more compact than its predecessor while maintaining an adequate machining area. Its width and height have been minimized to save the operator from the trouble of moving more than necessary even when multiple machines are installed, thus leading to higher productivity.

2. High Speed, High Accuracy, and High Rigidity

A lightweight moving body and highly rigid roller guide achieve high acceleration and deceleration.

A lightweight moving body and highly rigid roller guide achieve high acceleration and deceleration.

A spindle with a speed of 20,000 min-1 and a 2-axis direct drive table enable high-speed and high-accuracy machining.

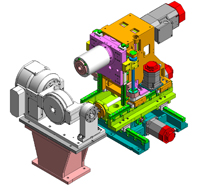

3. Horizontal-Type Simultaneous 5-Axis Control

A horizontal column with a low center of gravity travels along X-, Y-, and Z-axes, and the table rotates at a wide range of angles around A- and C-axes. This means complicated small-diameter multi-face machining can be performed with a single chuck. Also, the machine discharges chips with high efficiency, and ensures consistent product quality.

A horizontal column with a low center of gravity travels along X-, Y-, and Z-axes, and the table rotates at a wide range of angles around A- and C-axes. This means complicated small-diameter multi-face machining can be performed with a single chuck. Also, the machine discharges chips with high efficiency, and ensures consistent product quality.

Specifications

| Stroke | X-axis | mm | 200 (column traverse) |

| Y-axis | mm | 200 (column traverse) | |

| Z-axis | mm | 200 (column traverse) | |

| A-axis | deg | ±110 | |

| C-axis | deg | 360° | |

| Spindle | Spindle taper | - | NT30 |

| High speed, Coolant through | min-1 | 20,000 | |

| Feed | Rapid feed rate | m/min | 30 (X, Y, Z-axis) |

| Cutting feed rate | m/min | Max. 10 | |

| ATC | Tool to Tool | sec | 1 |

| Number of tools | - | 15 (optional 29) | |

| Tool shank | - | BT30 (Pull stud MAS P30T-2) | |

| Maximum tool dimensions | mm | φ 60 × 200 | |

| Maximum tool weight | kg | 2.0 (3.5 at low-speed ATC) | |

| control | Simultaneous 5 axes | ||

| Accuracy | Positioning | mm | 0.004 (in full travel) |

| Repeatability | mm | ±0.001 | |

| Machine | Width × Length × Height | mm | 1,050 × 2,690 × 1,850 |

| Weight | kg | 2,200 | |

| Power Source | Power supply | - | 3-phase AC 200 V ±10%, 50/60 Hz |

| Power capacity | kVA | Max.20 | |

| Air pressure | MPa | 0.4 - 0.6 | |

| Air consumption | L/min (ANR) | Max. 100 | |

Click here to make inquiries and requests for technical advice, specifications, price and catalogs. Please feel free to contact us.