JCC 603 Robo:CNC Robot hand Type Deburring and Washing Machine

Introducing the World’s First Ultrahigh-pressure Deburring System

Introducing the World’s First Ultrahigh-pressure Deburring System

A high-efficiency washing machine capable of transferring,

washing and drying, all in a single unit. The use of a highly rigid

robotic hand helps to reduce cycle time and decrease installation

space.

The world’s first MAX 245 MPa ultrahigh-pressure water jet enables

deburring of steel materials that had previously been difficult to

clean up.

Recommended Applications

- Automotive parts:Parts such as common rails, brakes, and engine and transmission components

- Construction machinery, hydraulic parts:Parts such as manifolds

- Any other parts having deburring problems

Introducing JCC603Robo

Advantage 1

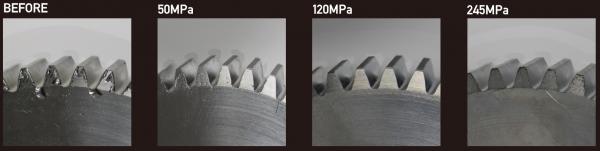

Deburring with a 245 MPa Ultrahigh-pressure Water Jet

Deburring with a 245 MPa Ultrahigh-pressure Water Jet

Unparalleled deburring with an ultrahigh-pressure Mach 2 water jet helps

give customer products a new sense of value.

Deburring Applications

- Deburring around cross-holes in cast iron and stainless steel

parts, removal of tough edge burrs due to milling, removal of

oxidation scale after hardening, etc.

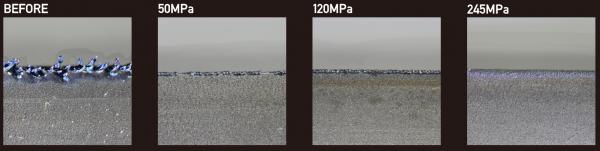

Deburring Applications:Material SS400

- Before deburring

- After deburring at 50 MPa

- After deburring at 245 MPa

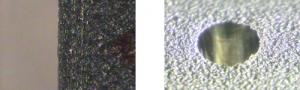

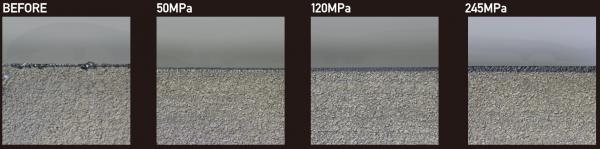

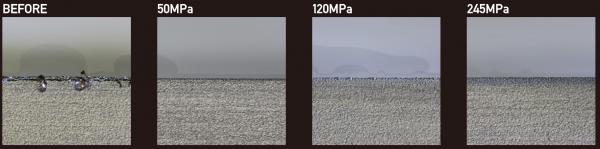

Other Washing Examples

- SUS630

- SS400

- TITANIUM

- INCONEL

Advantege 2

Newly Developed Drive Shaft

Newly Developed Drive Shaft

The use of a new 2-axes joint developed to make targeting small workpieces easier, combined with XYZ 3-axes high-speed, high positioning accuracy allows flexible and efficient hole and edge targeting.

Main Specifications

| Ultrahigh-pressure Washing Specifications | MAX 245 MPa x 4 L/min |

| Rinse Washing Specifications | 0.8 MPa x 100 L/min |

| Shaft Configuration (Stroke) | X-axis 650 Y-axis 500 Z-axis 500 mm A-axis ±90° C-axis 360° |

| Positioning Accuracy | 0.08 mm |

| Machine Dimensions | W 1,600 x L 2,660 x H 2,250 mm |

| Tank Station Dimensions | W 1,600 x L 2,800 x H 2,250 mm |

| Control Type | 3 direct axes + 2-axes joint CNC control |

| Waterproof Specifications | Fully-waterproof (electronic components completely separated from environment with water spray) |