POWTECH 2022

For further details, visit: https://www.powtech.de/en

Overview of the show

The mechanical processing technology community meets again from 27 - 29 September 2022

in Nuremberg, Germany. Some 700 companies will show their product spectrum - and we are

there, too!

We enclose a free admission voucher and sincerely invite you to visit us on stand 614 in Hall

3A at POWTECH 2022, where we will be pleased to present our latest products manufactured

in JAPAN.

Please register at https://www.powtech.de/en/visitors/tickets/voucher and print your

free ticket to have access to the event via fast lane.

| Dates | Germany 27 – 29 September 2022 |

| Venue | Nuremberg, Germany |

| Booth No. |

Hall 614 in Hall 3A |

| Exhibits |

|

Exhibits

Wet milling and dispersing device "Star Burst"

Maximum pressure is 245MPa (2.450 bar or 35.525 psi).

Star Burst Mini is the ideal partner in the development of cutting-edge, high value materials with extremely small material preparations with maximum yield.

[Applications]

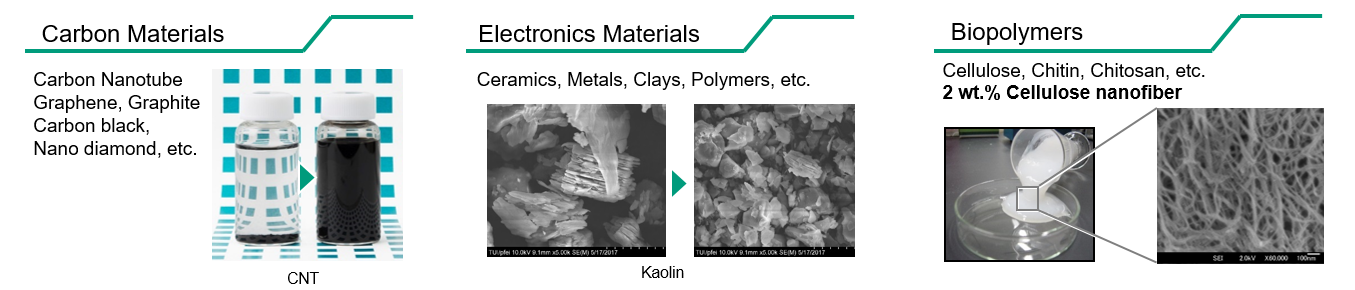

Carbon Materials and Clays for Batteries, Additives, Fillers, Cosmetics

Ceramics, Metals and Metal Oxides for Electronics

Pigments for Inkjet ink and Cosmetics

Emulsions for Cosmetics and Pharmaceuticals

Cellulose for nanofiber application

Twin Impeller Dry Mill "Dry Burst Mini (DB-100S CE)"

The "Dry Burst DB-100S CE" is a space-saving dry-type milling device that supports continuous production of low-contamination powder with a particle diameter of less than 10 µm.

The "Dry Burst DB-100S CE" is a space-saving dry-type milling device that supports continuous production of low-contamination powder with a particle diameter of less than 10 µm.

The powder is produced by colliding the raw material particles with one another using the air flow generated by two rotating impellers.

Compared with jet mills, the particle diameter can be better adjusted without over-pulverization.

Furthermore, the running costs are lower since the unit's power consumption is low.

Processing capacity

~4 kg/hr