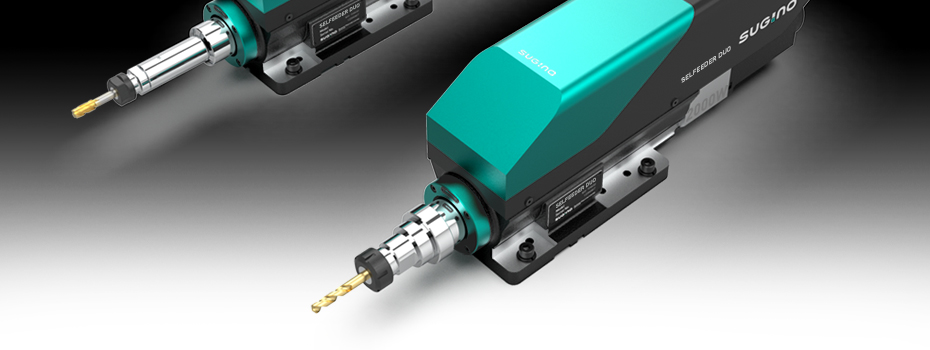

Compact, General-purpose drilling and tapping unit 「SELFEEDER DUO」

Half a century since its first release.

Now the most universal drilling & tapping unit for special-purpose machine is born.

Background to Development

In recent years, machining centers have become popular at parts manufacturing sites such as automobiles and precision machinery, which are easy to respond to component design changes in a short period of time, but special-purpose machines are used when mass-production of specific parts is temporarily required in tens of thousands of units.

However, there are many cases where parts production will be terminated within a year and the machining centers will turn idle after that.

Therefore, special-purpose machines that can be used for a long time have been required.

*What is a special-purpose machine?

A machine tool specialized for mass-production of specific parts in a short time.

For example, special-purpose machines are used for machining large parts that cannot fit into machining centers, long parts, and parts after three-dimensional molding that are difficult to transport and detach.

Now, we have developed a new product for processing units with the concept of "Turn special-purpose machines to Universal."

SELFEEDER DUO is a highly versatile drilling and tapping unit that can be used even when rebuilding a special-purpose machine.

Development Overview

This model is a new product of SELFEEDER series, the best-selling unit for special-purpose machines that efficiently mass-produce specified components.

This model is a highly versatile drilling and tapping unit gives the dedicated machine versatility, and can be mass-produced and compatible with a wide variety of products.

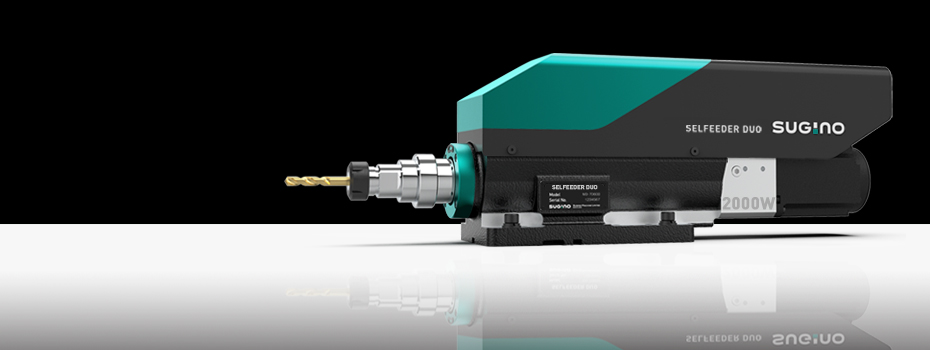

Specifications with enhanced versatility

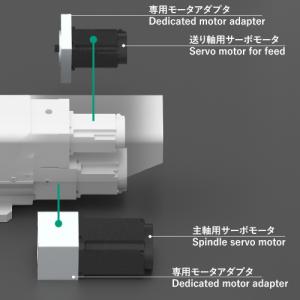

- Servo motors are installed on both spindle rotation and feed.

- Both Drilling and Tapping with one unit

- Capable of a wide range of machining diameters and inch screws

- International voltage specifications

Specifications that can be easily reused even in the rebuilding of special-purpose machines

- Easy to change the machining capacity by changing the servo motor

- Compatible with changing tools and holders by switching the spindle nose shape

- With SUGINO's multi spindle head, production can be even more efficient.

Automatic Drill Press Type Stands also available.

Multi-functional equipment capable of a wide range of machining diameters and inch screws.

Equipped with a machining operation program as standard spec. Easy setup and setup change.

History of "SELFEEDER"

In 1967, we developed SELFEEDER, a drilling unit dedicated for drilling holes, and together with SYNCHROTAPPER, a tapping unit dedicated for tapping, we have developed and sold units for machining applications.

SELFEEDER lineup has been broadly adapted to the demands of the market, such as high-speed rotation spec for machining small-diameter and low-speed and high-torque spec for machining large-diameter.

"SELFEEDER PNEUMATIC" is driven by the compressed air supplied from the air compressor for both rotation and feed, "SELFEEDER ELECTRIC" by the induction motor for rotation, and "SELFEEDER MECHATRIC" by the servomotor for feed. Rotation of "SELFEEDER VARIMEC" is controlled by the inverter. We are constantly evolving SELFEEDER and contributing to the improvement of our customers' productivity.

The application fields are not only the automotive industry but also the precision machinery, electronic equipment components and the aircraft industry. It is used in special-purpose machines for mass-production in a wide range of industries.

Click here for "selfeeder" and "synchrotapper" series up to now.