Skiving and Roller Burnishing Tools

Skive Roller is a tool that allows you to perform skiving and roller burnishing in one pass. It is perfectly suited for finishing of the inner surface of hydraulic cylinders for agriculture, heavy-duty construction, mining, etc..

Skiving and Rller Burnishing Machine is required when using Skive Roller.

What's Skive Roller: Skiving & Roller Burnishing Tool for hydraulic cylinders

The bore sizing and finishing processes of hydraulic and pneumatic cylinder tubes are widely used honing or grinding. Skive Roller is a multifunctional tool combined skiving and roller burnishing that allows you to perform those two processes in one pass, make it finished faster than horning.

What's Skive Roller: Features & Specifications

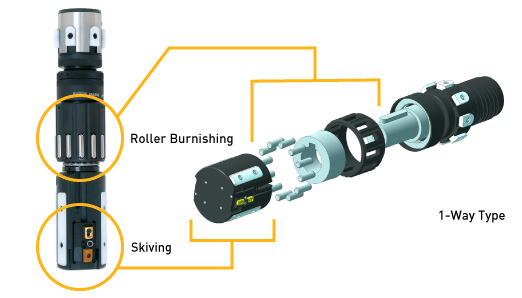

Skive Roller is a tool that combines a skiving head and a roller burnishing head,

and enables to significantly reduce machining time compared to horning.

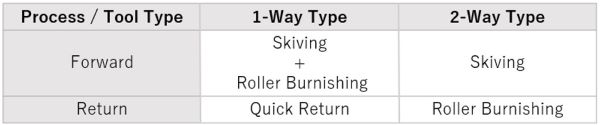

Skive Roller can be selected from 1-way and 2-way types according to the purpose.

1-way method

Skiving and roller burnishing process is performed in the forward feeding direction, and operation is completed very quickly. With the 1-way operation, skiving and roller burnishing work in the same feeding direction, and operating time is quite short.

The operating conditions must be set commonly for each skiving or roller burnishing.

2-way method

The tool skives on the forward stroke and burnishes on the return stroke. With the 2-way operation, as skiving and roller burnishing operations are completed in each stroke, optimizing of speed and feed can be made separately for skiving and roller burnishing. However, with the 2-way operation, the operating time can be longer since quick retract(return) is not possible.

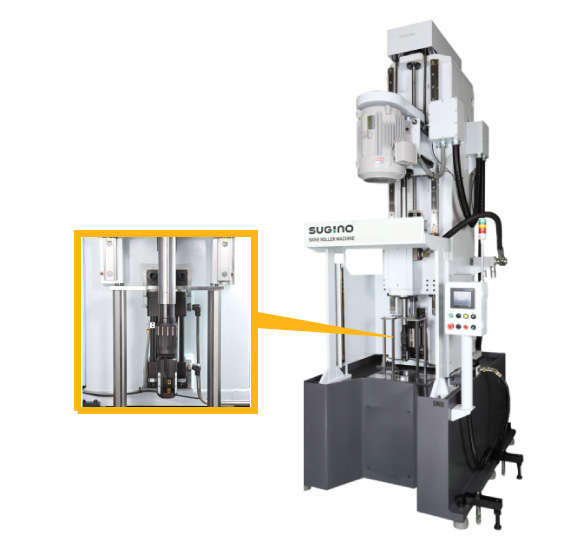

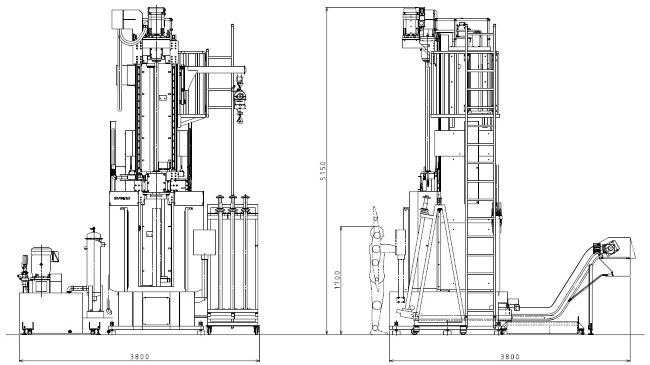

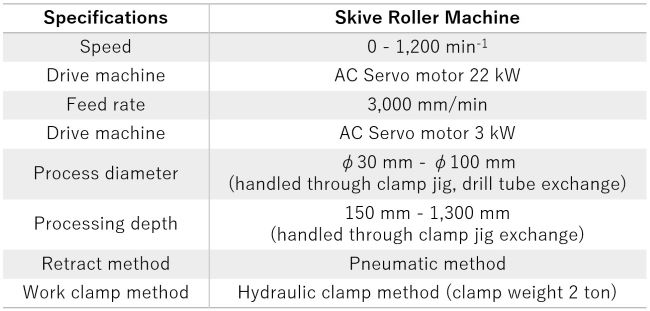

Skive Roller Machine: Vertical Skiving and Roller Burnishing Machine

Sugino Vertical Skiving and Roller Burnishing Machine "Skive Roller Machine" provides an optimal finishing as well as bore sizing for hydraulic cylinders. It is capable of up to 1,300mm length.

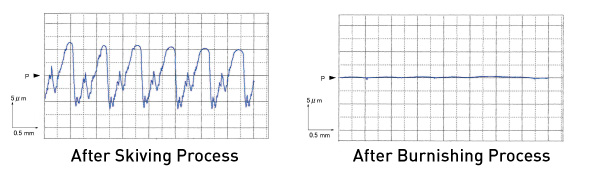

Surface Roughness Data

Workpiece Detail Material: STKM13C, Size: ID32xOD40

Dimensions and Specifications

Click here to make inquiries and requests for technical advice, specifications, price and catalogs. Please feel free to contact us.