Dimple Forming Tools

Micro Dimple Forming Tool: surface quality improvement tool

The Micro Dimple Forming Tool surface quality improvement tool is a jig that forms minute dimples (dents) of a depth of several μm in metal surfaces. It includes types for inner, outer and flat surfaces.

The Micro Dimple Forming Tool surface quality improvement tool is a jig that forms minute dimples (dents) of a depth of several μm in metal surfaces. It includes types for inner, outer and flat surfaces.

Applicable machines: Drill Presses, Machining Centers, Lathes

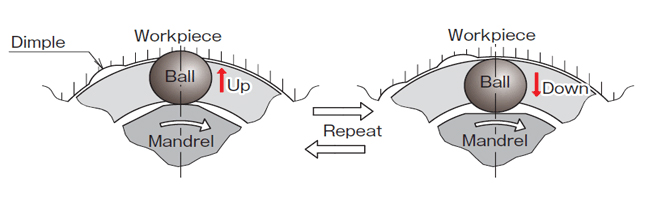

Principles of the Micro Dimple Forming Tool surface quality improvement tool

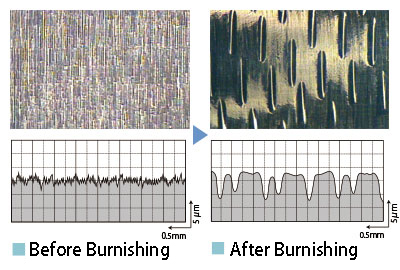

When you rotate and feed the tool, it passes through the workpiece, and as the bore sticks out from the outside, a micro dimple (an extremely detailed dent of a depth of several μm) is formed. The surface where the dimple is formed is a processed surface with excellent abrasion resistance, seize resistance and sliding characteristics due to the oil pot effect. For inner surfaces, there is a dedicated tool (φ5 and over), and for flat surface and outer surfaces, there are all-purpose tools.

When you rotate and feed the tool, it passes through the workpiece, and as the bore sticks out from the outside, a micro dimple (an extremely detailed dent of a depth of several μm) is formed. The surface where the dimple is formed is a processed surface with excellent abrasion resistance, seize resistance and sliding characteristics due to the oil pot effect. For inner surfaces, there is a dedicated tool (φ5 and over), and for flat surface and outer surfaces, there are all-purpose tools.

They can be applied to all metals below HRC40.

Processing Examples

Internal processing of aluminum materials

- Used machinery: all-purpose miller

- Work materials: A2017

- Rotation speed: 1,000 min-1

- Feed rate: 1.5 mm/rev

Application Examples

- Hydrodynamic bearing

- Rotating and sliding surfaces such as pistons and connecting rods

- Substitution of oil-free bushings and bearings

|  |  |

|---|

Click here to make inquiries and requests for technical advice, specifications, price and catalogs. Please feel free to contact us.