What is Water jet method|Cellulose nanofiber

What is Water jet method

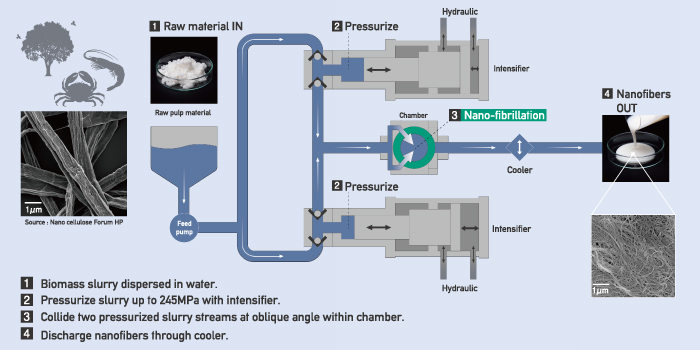

Disperse the raw pulp material in water, pressurize and inject slurry up to 245MPa (35,525psi, 2,450 bar) at a speed of Mach 2. Fiber materials are fibrillated into nanofibers by colliding two high pressure water jet streams at an oblique angle.

It is a clean and innovative method that can be manufactured only water and raw materials.

Benefits of Water jet method

- Gentle on the environment and human body

- Minimum Contamination

- High efficiency and continuous production

- Degree of polymerization and crystallinity are not substantially reduced

- Possible to handle high viscosity and long-fiber material

- Easy to customize fiber length and fiber width

All manufacturing equipment made by Sugino Machine

Since the development of “Sugino Pumps” in 1964, we have fostered our own water jet technology to provide the best solutions for out customers over 50 years.

The Water jet method that produces biomass nanofiber is also on the extension line, and all the equipment to be used are made by Sugino Machine.

As a industrial machinery manufacturer, a wide range of nanofiber materials with various characteristics are achieved.