EVADRY: Compact Vacuum Dryer

EVADRY

EVADRY is a vacuum dryer uses simple principal,which never allows any water droplets left even in the bottom of deep holes, firmly makes whole water gone from your product.

Thoroughly dries even complex-shaped workpieces to deep depths with just the push of a button. Contributes to automation and manpower saving.

In addition, it consumes significantly less power than air blowers, making it an environmentally friendly, eco-friendly device.

Video

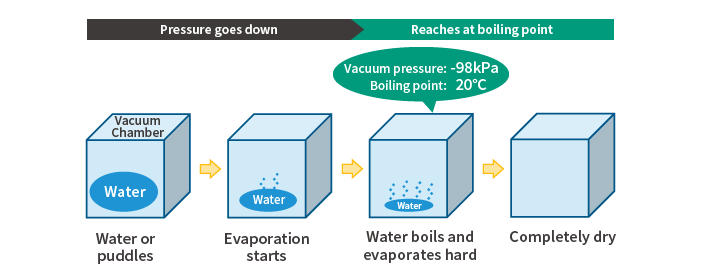

What is vacuum drying? – Principle

By creating a vacuum, the moisture remaining on the part is thoroughly dried!

When the air pressure drops, water boils at temperatures below 100 ℃. By using this principle and lowering the air pressure inside the machine to a vacuum, even the moisture remaining in the deep part of the parts. Thoroughly evaporate and dry.

Replacing air blow systems significantly reduces power consumption and CO2 emissions!

Are you aware that air blowing spends tons of energy?

By replacing the air blow drying process with vacuum drying, power consumption is greatly reduced.

If you manually blow the air, you can also reduce labor costs, so we will strongly promote cost reduction.

CO2 emissions per hour

| Air blow | Vacuum drying | |

|---|---|---|

| CO2 emissions | 10.5kg/h | 1.6kg/h |

* The reduction rate is an actual measurement value of an in-house test in the cylinder head’s dryness. The reduction rate changes by the system requirements.

Features of the “EVADRY” vacuum dryer

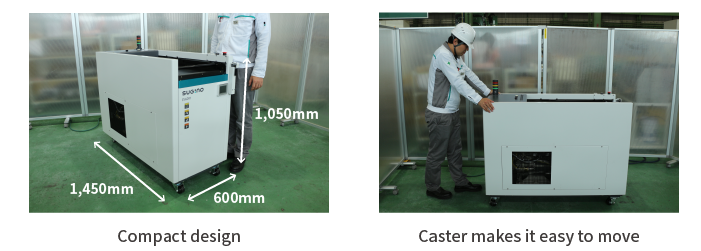

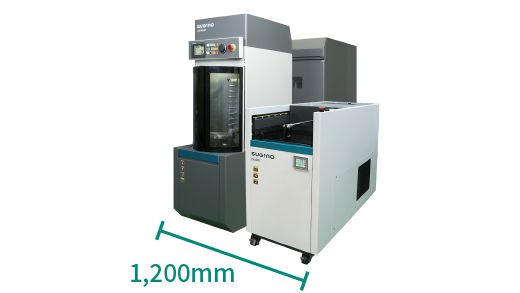

Compact and on castors, easy to handle!

The compact design of the EVADRY, with a height of 1,150 mm and a width of 600 mm, makes it easy to locate.

Equipped with castors, it is easy to relocate the machine. This compact vacuum dryer is easy for anyone to handle.

Easy operation, free from manual air blowing!

Simply set the workpiece and press a button for easy and thorough drying.

- This frees you from manual air blow drying work.

- This saves manpower and reduces costs.

- The workpiece is cooled by the heat of vaporization during evaporation, which also allows for a reduction in the cooling process time.

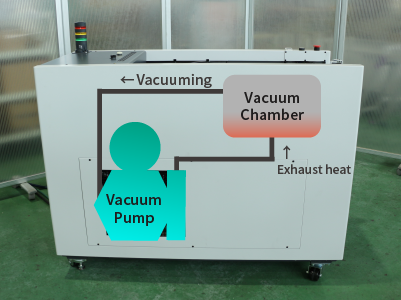

Highly efficient drying using the exhaust heat of the vacuum pump!

In vacuum drying, raising the temperature of the workpiece allows the moisture to evaporate more efficiently.

EVADRY uses the exhaust heat of the vacuum pump to raise the temperature inside the vacuum chamber and improve the drying degree.

Despite its compact body, the EVADRY offers efficient drying accuracy.

The auto-shutter specification supports automation and labor-saving as well!

The auto-shutter features support automation and labor-saving with the use of robots and gantry loaders.

By installing it adjacent to the washing machine, you can efficiently consolidate the parts washing and drying processes.

Specification

You can choose from four models according to the workpiece size and application.

| EVADRY | EVADRY-WIDE | ||||

|---|---|---|---|---|---|

| Model | EVD-22 | EVD-22A | EVD-22WA | EVD−55 | |

| Vacuum pump | kW | 2.2 | 5.5 | ||

| Vacuum attainment pressure |

kPa | 1.3kPa or less | |||

| Size of vacuum tank |

mm | 400×375×275 | 400×375×270 | 700×500×150 | 700×500×400 |

| Door | — | Manual door | Automatic door with safety light curtain |

||

| Settings | — | Up to 15 different operation times can be set. | |||

| Size(W×D×H) | mm | 600×1,450×1,050 | 600×1,450×1,150 | 900×1,800×1,270 | |

| Weight | kg | 500 | 600 | 800 | 1,000 |

Options

Workpiece Rotation Specifications

By rotating the workpiece inside a vacuum chamber, the moisture accumulated in deep or contact areas of the workpiece is moved, thereby promoting drying.

The drying time can be reduced by 15% to 25%.

Hot Air Blowing

By heating small parts and resin products, which are difficult to dry in a vacuum, the drying process is accelerated.

The drying efficiency can be enhanced by 10% to 15%.

Application Examples

Complete drying of workpieces (capable of handling multiple pieces and irregular shapes)

Rust prevention measures

Energy-saving measures for the drying process

Case Studies

Automotive parts / Semiconductor components / Resin products / Carbon materials / Magnesium composite materials / Construction machinery parts / Hydraulic components , etc.

Comparison with other methods

| Advantage | Disadvantage | Drying level | CO2 reduction rate * | |

|---|---|---|---|---|

| Air blow | Easy to install because only factory air is used | ・Loud noise ・High power consumption |

There is no drop of water fall without the pool ball | – |

| Blower | Self-generated air is used, saving energy compared to air blow | Lower air pressure than air blow, so less accurate drying | Numerical in there is no pool ball fall extent | 44.4% |

| Vacuum dryer |

・It is possible to dry completely ・Conservation of energy as well as the blower |

Oils cannot be dried | Complete dryness | 85.1% |

* The reduction rate is an actual measurement value of an in-house test in the cylinder head’s dryness. The reduction rate changes by the system requirements.