High Viscous Slurry Processing Unit for STAR BURST

STAR BURST High Viscous Slurry Processing Unit

Allows for efficient continuous processing of high viscous slurries.

“High Viscous Slurry Processing Unit” is a specialized heat exchanger unit designed exclusively for STAR BURST and capable of handling high viscosity fluids.

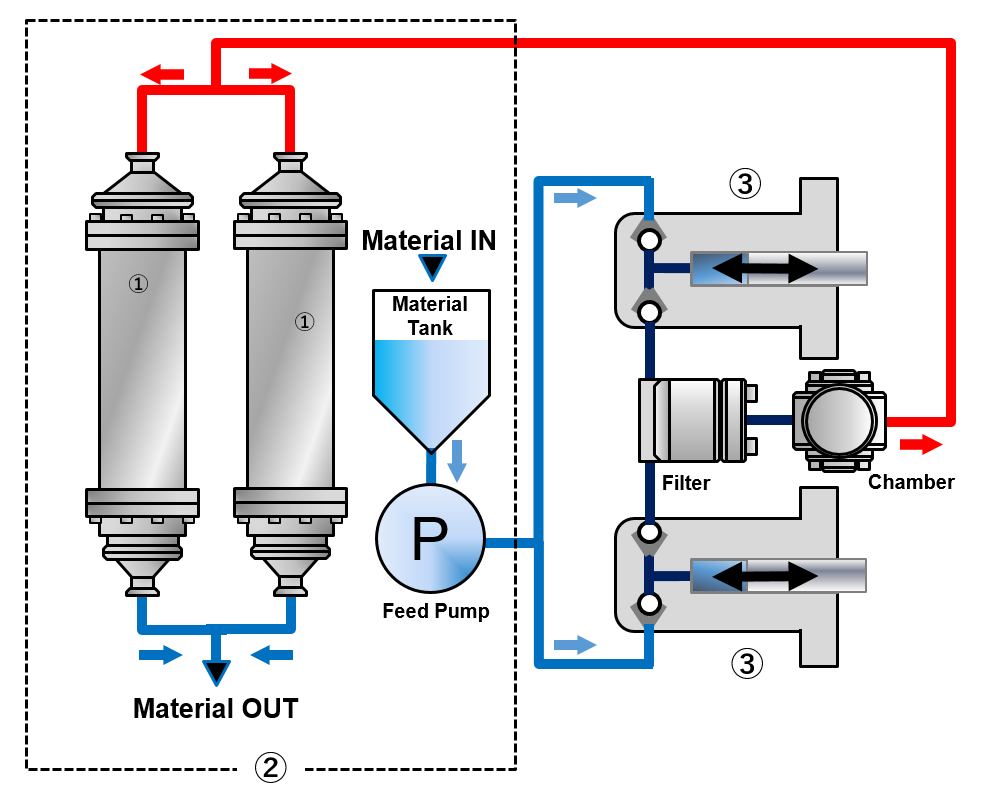

Unit Components

① Multiple Pipes Type Heat Exchanger

Safe and efficient cooling!

All stainless steel and solvent-resistant!

User-friendly Maintenance !

② Dedicated Wagon

Compact layout of raw material tank, feed pump, and heat exchangers

Quick Release Design

③ Intensifier for High Viscous Slurry

Less Flow Loss Design

User-friendly Parts Replacement

Specification

| Available Model | STAR BURST LABO |

| STAR BURST 10 | |

| External Dimensions (Includes Dedicated Wagon) | W 554×D 546×H 1,396 mm |

| Total Weight | Approx. 100 kg |

| Max. Throughput | 0.5 – 0.9 L/min |

| Max. Pressure | 245 MPa ※1 |

| Wetted Part Material | SUS, PTFE |

| Reference Viscosity | 10,000 mPa·s (20℃) ※2 |

| Available Solvent | Water, Organic Solvent etc. |

※1 Shall not exceed the boiling point of the solvent.

※2 Available over 10,000mPas depending on the material fluidity

Utility

| Air | 0.5 MPa x 35 NL/min |

| Cooling Water | Less than 20 ℃ x 10 L/min |

|

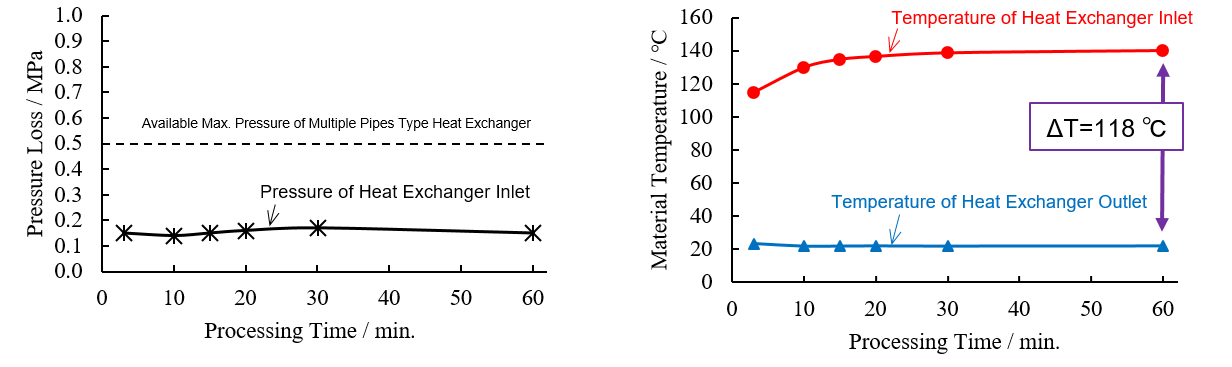

Test Sample

| Material | Silicone Oil |

| Fluid Property | Newtonian Fluid |

| Viscosity | 12,820 mPa・s(20℃) |

| Equip.Model | Star Burst Labo |

| Chamber | Single Nozzle Chamber |

| Pressure | 245 MPa |

| Throughput | 700 g/min |

| Processing Time | 60 min |

| Feed Pump Air Pressure | 0.5 MPa |

| Heat Exchanger QTY | Two units Parallel Connection |

| Cooling Water Temp. | 20℃ |

| Cooling Water Flow Rate | 10 L/min |