Self-Center SC-H40: #40 Horizontal Compact Machining Center

SELF-CENTER SC-H40

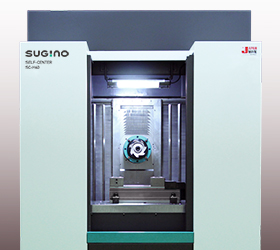

“Self-Center H40” is a horizontal type compact machining center having #40 spindle taper.

The machine employs a column traverse method. It is suitable for automation line.

Product introduction video

Basic specifications

Features of the H40

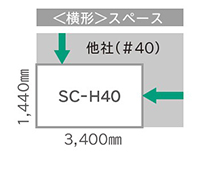

1. Space-saving Design

Required installing space is about 4.9 m² despite of being equipped with #40 spindle taper.

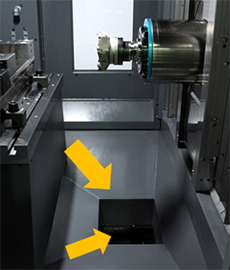

2. Improved chip-flow.

It employed a center trough bed structure, improving chip-flow.

3. High rigidity

High rigidity main spindle capable of heavy cutting is mounted. The machine employs a column traverse method, so that large fixtures can be smoothly installed.

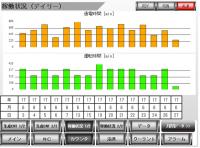

4. Enhancement of monitoring function and Data utilization

It is possible to monitor the production number of the workpieces and the operation status in real time.

By accumulating and analyzing the data, you can take advantage of the recovery in the event of preventive maintenance or failure.

Specification

| Stroke | X-axis | mm | 400(column traverse) |

|---|---|---|---|

| Y-axis | mm | 410(column traverse) | |

| Z-axis | mm | 410(column traverse) | |

| Table | Working area | mm | 700×400 |

| Allowable load | kg | 700 | |

| Spindle | Spindle taper | – | NT40 |

| Standard | min-1 | 10,000 7.5kW | |

| Coolant through | min-1 | 10,000 7.5kW | |

| Feed | Rapid feed rate | m/min | 60 (X, Y, Z-axis) |

| Cutting feed rate | m/min | Max. 10 | |

| Min. programmable Unit | mm | 0.001 | |

| Accuracy | Positioning | mm | 0.004 (in full travel) |

| Repeatability | mm | ±0.001(all spindle) | |

| ATC | Number of tools | – | 25(optional 33) |

| Tool to Tool | sec | 1.6(low-speed mode 2.6) | |

| Tool shank | – | BBT40 (Pull stud MAS P40T-1) |

|

| Max. tool dimensions | mm | Max.φ100×300(With adjacent tool) | |

| Max.φ150×300(No adjacent tool) | |||

| Max. tool weight | kg | 5.0(8.0 at low-speed ATC) | |

| Tool selection | – | Memory random | |

| Machine | Width×Length×Height | mm | 1,440×3,400×2,140 |

| Weight | kg | 6,300 | |

| Power Source | Power supply | – | 3-phase AC 200V±10%、50/60Hz |

| Power capacity | kVA | Max.43 | |

| Air consumption | MPa | 0.4~0.6 |

Note: Specifications in this catalogue are subject to change without prior notice for further improvement.