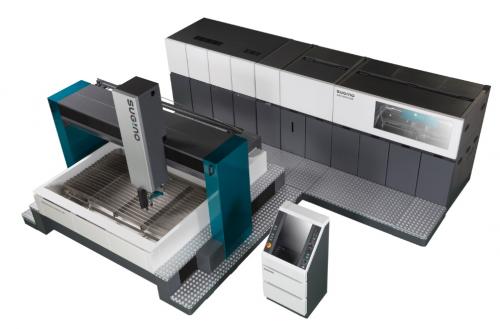

Abrasive Jet Cutter NC-5AX: Simultaneous 5-axis Control Abrasive Type Ultrahigh-Pressure Water Cutting Equipment

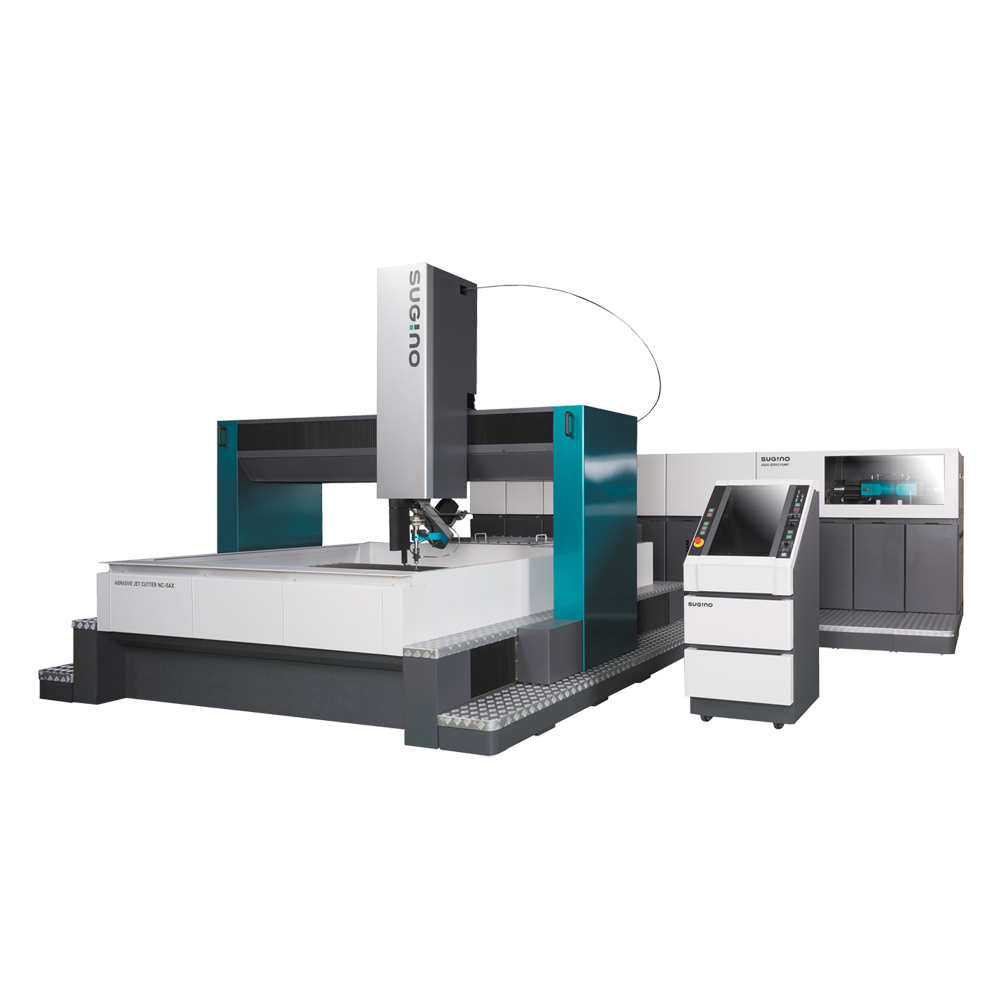

ABRASIVE JET CUTTER NC-5AX

Single-point focus specification high-end model

Reflecting on the founder’s dedication to user-friendliness, we have completely redesigned the Water Jet Cutter, a flagship product of Sugino Machine, to enhance its functionality and operability.

Features

The Abrasive Jet Cutter (NC-5AX) has been improved in response to customer feedback, addressing various aspects such as functionality, operability, ease of cleaning, and installation space. Below are its features:

Equipped with the new hydraulic intensifier type pump, “Aqua Servo Pump” !

- Stable supply from low to high pressure with a servo motor-driven closed-circuit hydraulic system and proprietary control technology.

- 75% reduction in power consumption when water jet is stopped.

- 75% reduction in amount of water used.

- 82% reduction in operating oil used.

High-speed, High-precision

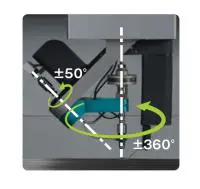

High rigidity by dual-axis gantry, low center of gravity and symmetry design, and 5-axis controlled single-point focus nozzle head with a maximum tilt angle of 50 degree realize high-speed, high-precision machining.

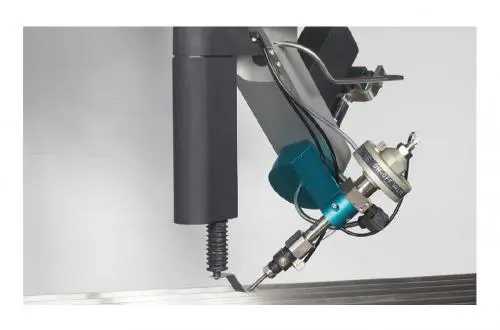

Mechanism with single-point focus specifications

It’s a single-point focus specification where the A-axis and C-axis rotate around the machining point of the nozzle.

When performing cutting operations, adjustments to angle and height can be made using the rotation of the A-axis and C-axis, enabling the quickest determination of nozzle orientation. This efficient method avoids the need to move the entire upper drive unit with each nozzle orientation change, allowing for efficient machining.

The A-axis can tilt up to ±50 degrees, while the C-axis can rotate ±360 degrees.

Video

Capable of processing a wide range of materials from metals to brittle materials.

Metal products: Efficient processing of rare materials with high yield.

Material processing: Process materials unsuitable for laser or plasma cutting without thermal alteration, and manufacture various test specimens.

Aerospace: CFRP, titanium, duralumin, etc.

New materials: Glass laminates, cermets, FRP, ceramics, etc.

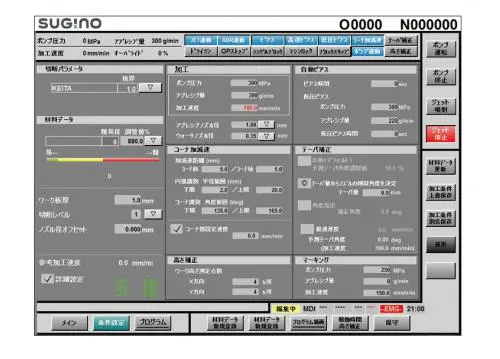

Simple Operations

Powered by the “Sugino Jet Processor,” which harnesses years of machining know-how compiled into a database. Simply entering data such as material and thickness allows anyone to start machining easily.

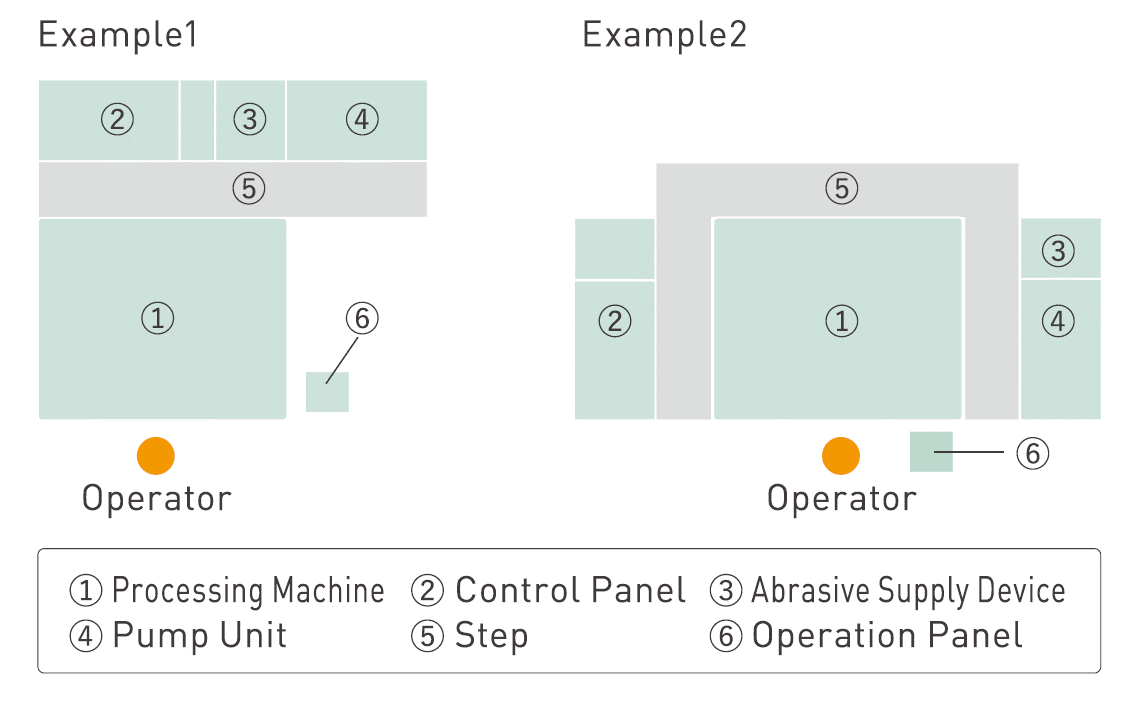

Flexible Layout Options

We have modularized the pump unit, abrasive supply device, control panel and piping cover step. This allows flexible layout adjustments to suit various working environments.

Wide Range of Convenient Functions

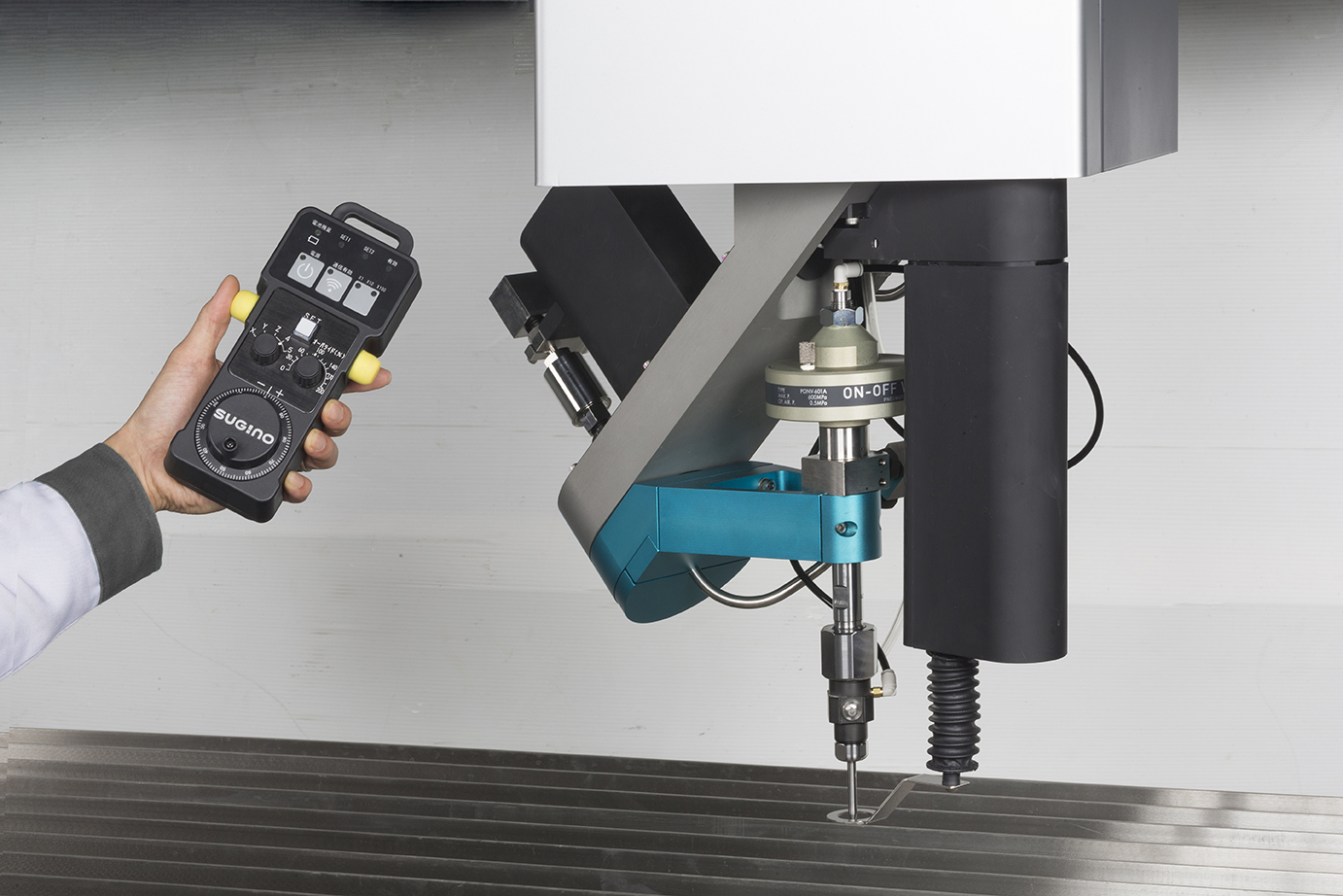

Wireless manual pulse controller

Boost prductivity with the wireless controller

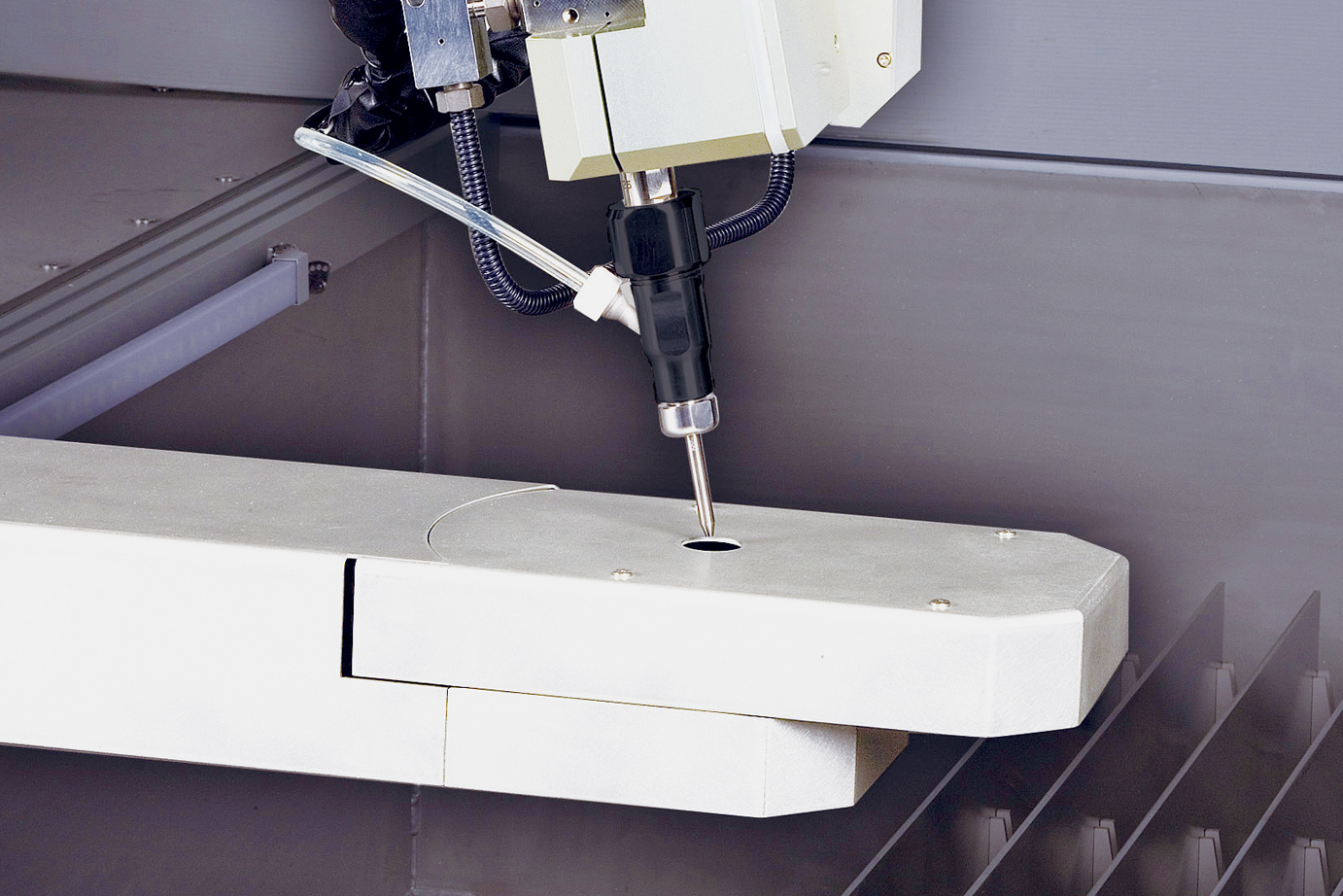

Automatic machining bit correction unit

An unit that automatically measures and corrects machining points that are misaligned after maintenance, such as nozzle replacement.

Designed for Functionality

Storage box, foldable work table

Recess for toe, side step, auxiliary handle

Design considerations for ease of cleaning and optimized workflow.

Specifications

| Effective Stroke | X-axis | mm | 800~5,800 *1 |

| Y-axis | 1,600 or 2,600 *2 | ||

| Z-axis | 200 | ||

| A-axis | deg | ±70 | |

| C-axis | ±400 | ||

| Maximum Movement Speed | m/min | X,Y-axis: 10 Z-axis: 5 | |

| deg/s | A-axis: 90 C-axis: 180 | ||

| No. of Control Axes | – | 5 axis | |

| Amount of Abrasive Supplied | g/min | 100~600 | |

*1 The X-axis stroke is 800 to 5,800mm, available in 1,000mm increments.

*2 The Y-axis stroke can be selected from 1,600mm or 2,600mm.

*3 Specifications above are just an example.