GUN FEEDER: Small-Diameter & Deep Hole Gun Drilling Machine

GUN FEEDER

The “Gun Feeder” is a high-precision, high-efficiency gun drilling machine developed exclusively for small-diameter and deep holes.

It is optimized for drilling small-diameter and deep holes used in applications like fuel injection nozzles, sleeve pins for molds, and parts for hydraulic machines.

Features

High-precision Drilling

This short length gun drill can be used with Sugino’s special whip guide system (slide type).

This allows it to control vibration and the drill with high precision.

Also, it is possible to start drilling very slowly to control hole curvature.

Outstanding Performance

A numeric keypad can be used to easily enter data required for gun drilling.

Also, the values input for e.g. rotation speed and feed rate can be checked on a single screen.

Type

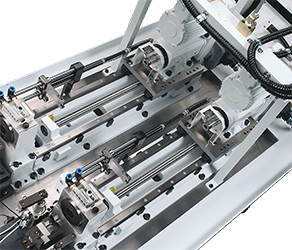

Single-spindle Model/Two-spindle Model

The two-spindle model optimized for drilling holes of different sizes and increasing productivity, and the single-spindle model equipped with a workpiece rotation unit are offered.

Single-spindle Model

Two-spindle Model

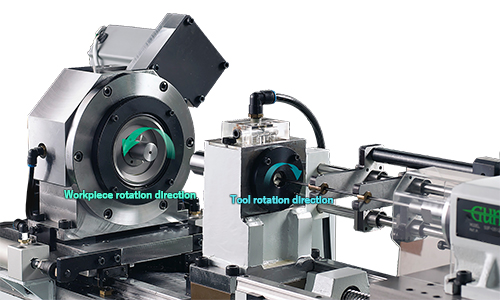

Gun Feeder LR (with Workpiece Rotation Unit)

“Gun Feeder LR” is a highly precise gun drilling machine with a workpiece rotation unit specialized for drilling small-diameter and deep holes.

The off-center accuracy of drill holes can be improved dramatically by rotating the workpiece opposite to the gun drill.

High-precision Drilling

Drill hole misalignment can be reduced to 1/3 or less by the Sugino workpiece rotation device. (as per Sugino test data)

No Alignment Adjustment Needed

With the automatic centering whip guide system (optional), there is no need for manual alignment between the tool and workpiece.

Gun Feeder with X-Y Table

It is a high precision gun drilling machine dedicated to machining small and deep holes equipped with XY table.

Process consolidation or continuous processing by taking multiple workpieces is possible.

Also, by moving the work mounting table, versatility of work diameter and processing position will improve.

Various types of multiple workpieces can be processed in one cycle.

By positioning in the X-Y direction, the hole position can be changed freely, and it can flexibly process workpieces with different outer diameters and lengths.

X, Y axis servo drive has achieved high-precision positioning.

Application Examples

- Parts of medical devices

- Parts of semiconductor manufacturing devices

- Sleeve pin of molds

- Parts of electronic devices

- Oil hole of cutting tool

- Jig table

- Mold etc

Specifications

| Item | Single-spindle model | Two-spindle model | ||

| Drill hole size | mm | 0.9 – 5.0 diameter | ||

| Drill hole depth | mm | Max. 300 (Note 1) | ||

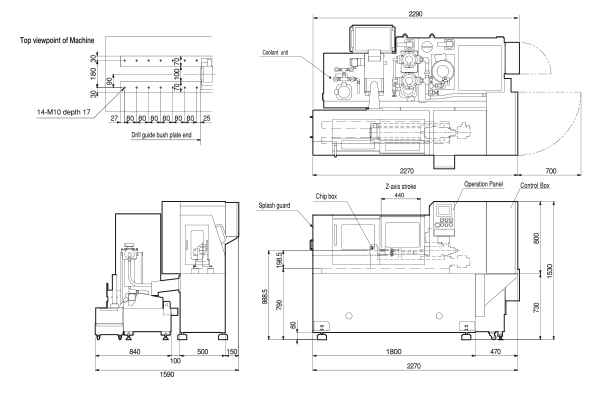

| Z-axis stroke | mm | 440 | ||

| Spindle | Rotation speed | min-1 | 2,000 – 12,000 | |

| Spindle motor | – | 0.75 kW 2P | ||

| Feed shaft | Feed shaft motor | – | 0.5kW, AC Servo Motor | |

| Minimum setting unit | mm | 0.01 | ||

| Coolant unit | Tank capacity | L | 320 | 570 |

| High pressure pump | – | 6 L/min 11 MPa (Note 2) | ||

| Motor 4.0 kW 4P | Motor 4.0 kW 4P ×2 | |||

| Washing pump | – | Motor 4.0 kW 2P | ||

| Filter pump | – | Motor 4.0 kW 2P | ||

| Line filter | – | 1 | 2 | |

| Filter | µm | 20 | ||

| Machine | Width × Depth × Height | mm | 2,290 × 1,590 × 1,530 | 2,720 × 2,060 × 1,640 |

| Weight | kg | 1,500 | 2,000 | |

Notes:

1. Specifications other than the above are optional. Please refer to the catalogs for further details or contact your

nearest office.

2. The drilling depth varies according to the gun drill length used. A whip guide is provided at one location with the standard gun drill. Depending on the gun drill used, whip guides at two or three locations (optional) may be required.

3. The maximum working pressure of the high pressure pump is 11 MPa (when the viscosity is 10 mm2/s(cSt)). However, the pressure and flow vary with the viscosity of the fluid, and the diameter and length of the gun drill used.

4. Standard coating color / mount: Dark gray (Munsell N3.0), splash guard: White. Front door: Metallic blue

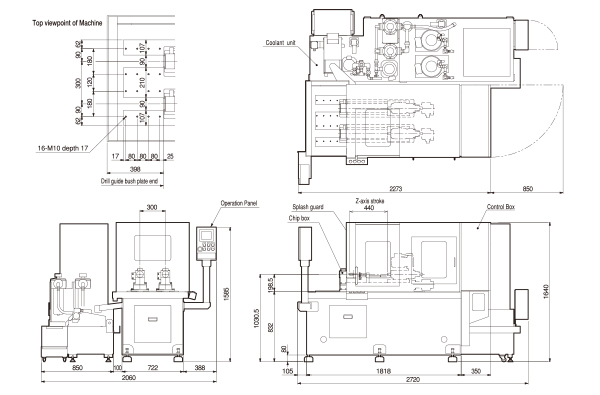

Dimensions

Single-spindle Model (mm)

Two-spindle Model (mm)