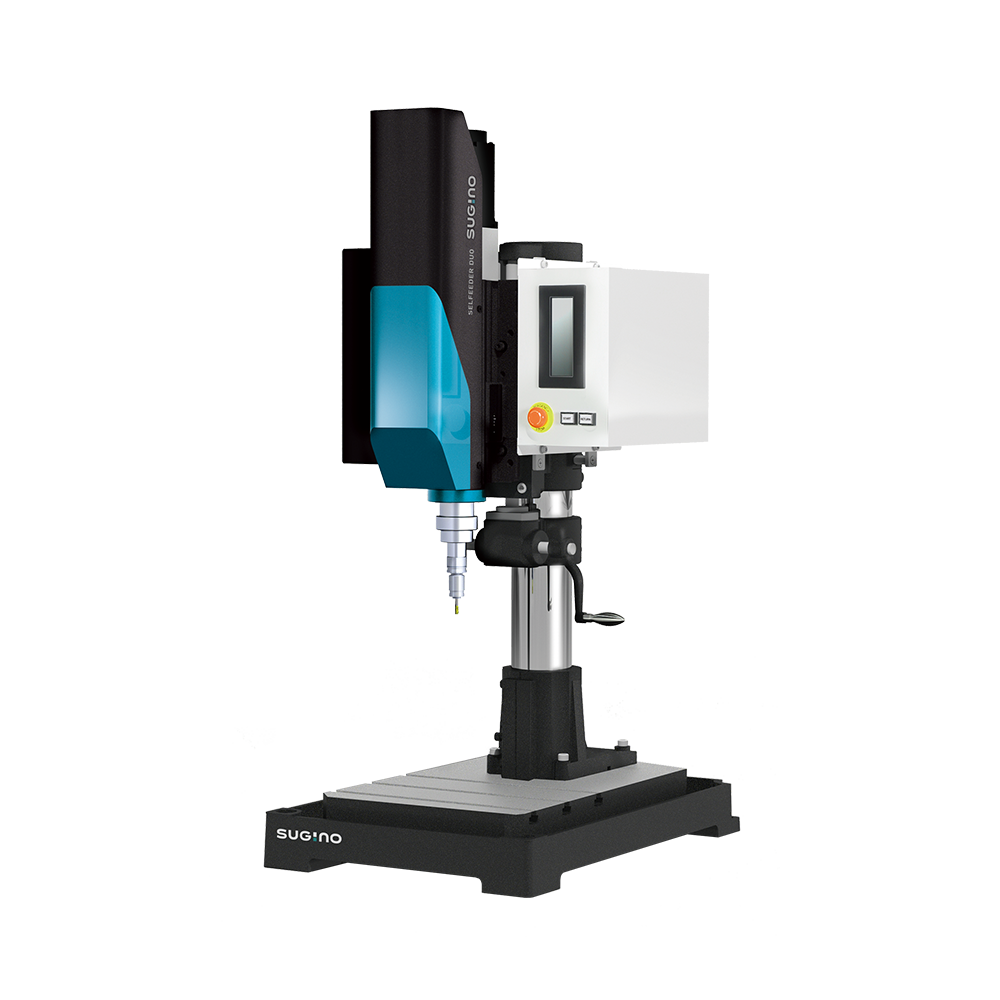

STANDRILL SELFEEDER DUO : Automatic Drilling and Tapping Stand

STANDRILL SELFEEDER DUO

Same-day operation is possible! Drilling and tapping can be easily automated with a single unit.

This is an automatic drill press type stand.

Max. drilling size ……… φ13(Steel)/ φ18(Aluminum)

Max. tapping size ……… M10(Steel)/ M14(Aluminum)

Max. stroke ……………… 150mm

Max. rotation speed…… 10,000min-1

Feature

Leave it to us for renewal of aging tapping drilling machines and after-sales service.

Easy and safe operation

200V power supply for immediate operation

After delivery, you can start operating immediately.

Easy programming

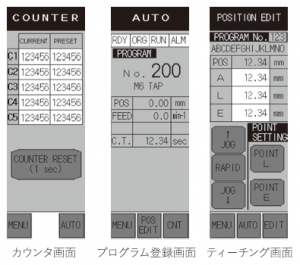

4.5 inches small touch panel for manual operation and program setting.

Preloaded programs of machining patterns required for drilling and tapping, easy to program by entering cutting start or end point, spindle speed and so on.

Various functions

Preset counters 6 digitsx5

Capacity of total program records 200 records

Easy teaching function included

Easy and intuitive setting buttons

Additional options available for customization

By adding external I/O signals (optional), continuous control of customer-provided jigs and safety doors is possible.

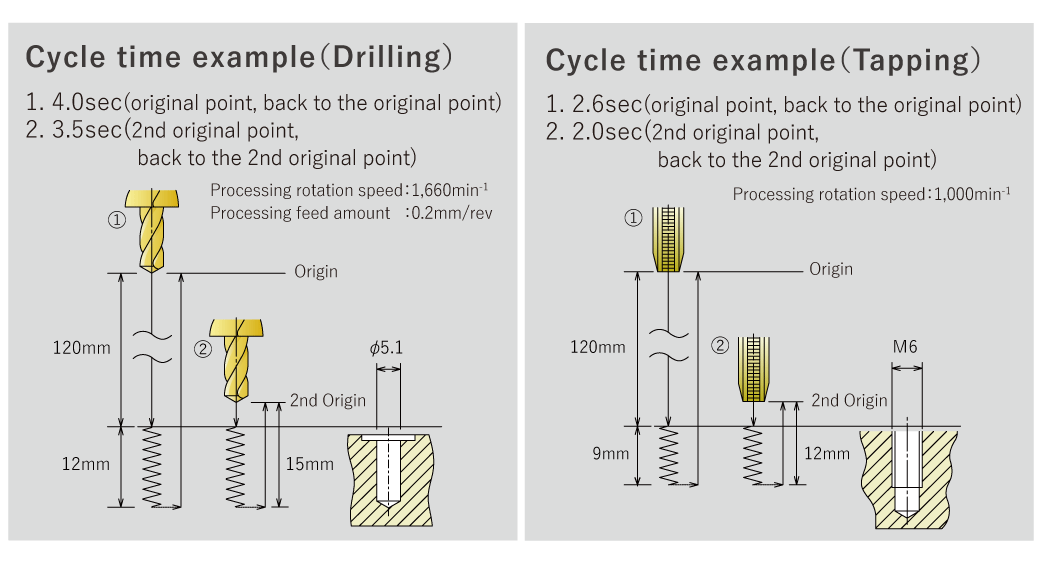

Drilling and tapping by a single unit

High power servo motors for main spindle and feed axis enable very easily to change programs,

from drilling to tapping, or change thread pitch just by a touch panel.

Also high precision tapping is possible by perfect synchronization.

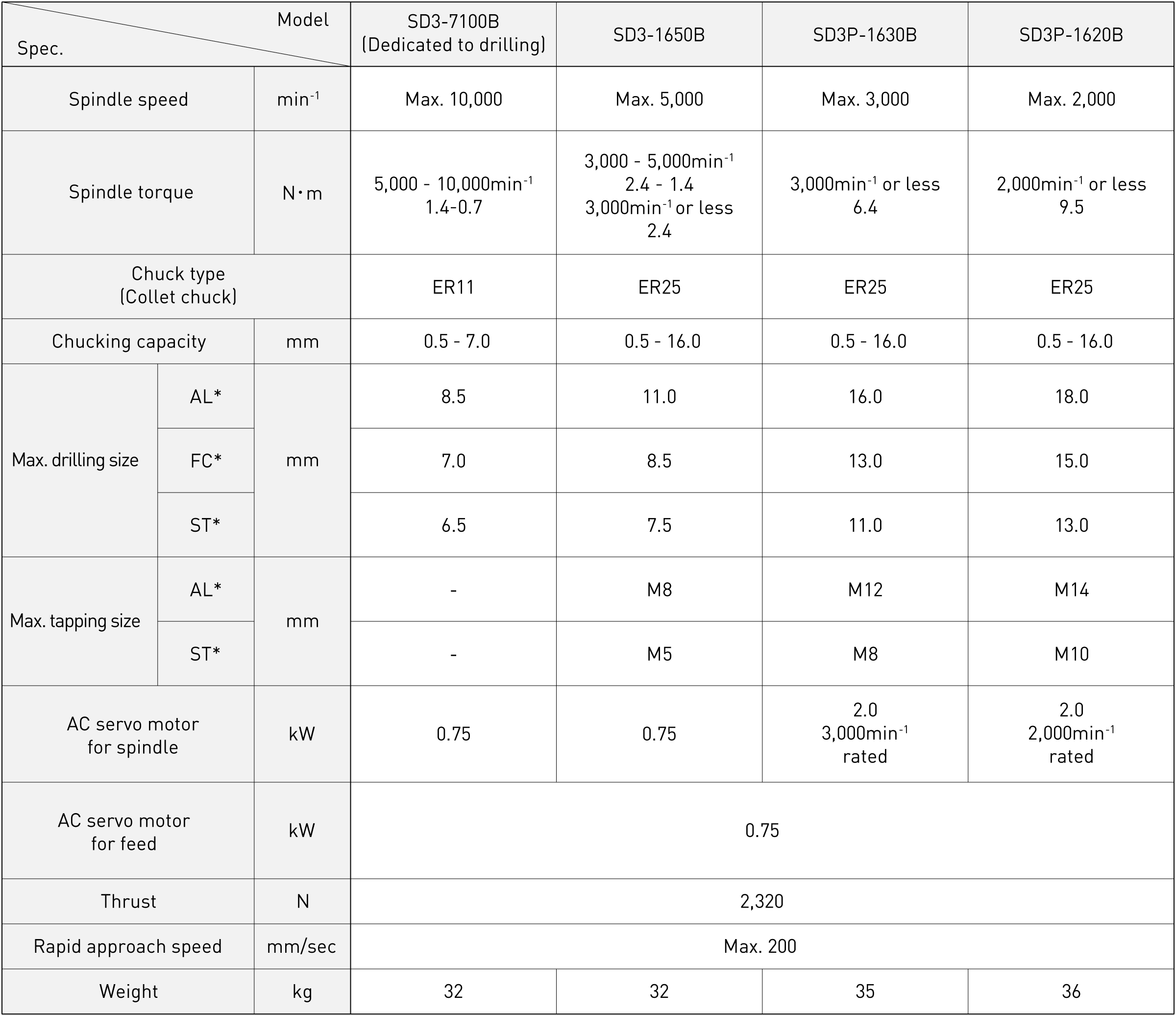

Specifications

Notes:

Select a model based on workpiece specifications, machinability, tool specifications and cutting speed.The maximum drilling capacity shown above is the value at a drilling depth of twice the drill diameter.Tapping capacities are conditional on the depth of tapping being limited to 1.5 times of the tap diameter.

If the maximum drilling capacity exceeds the chucking capacity, special tools (with steps) shall be prepared by the customer.

If your drilling and tapping needs exceed the figures in the capacity chart, please contact the nearest sales office.

ER collet is adopted for spindle nose. Use collet ER-GB when chucking a tap.

Misalignment between a pre-hole and a tap can cause early tap damage, select a tap holder.

A servo motor for feed is with a holding brake, “B” is added to the end of SELFEEDER DUO model number.

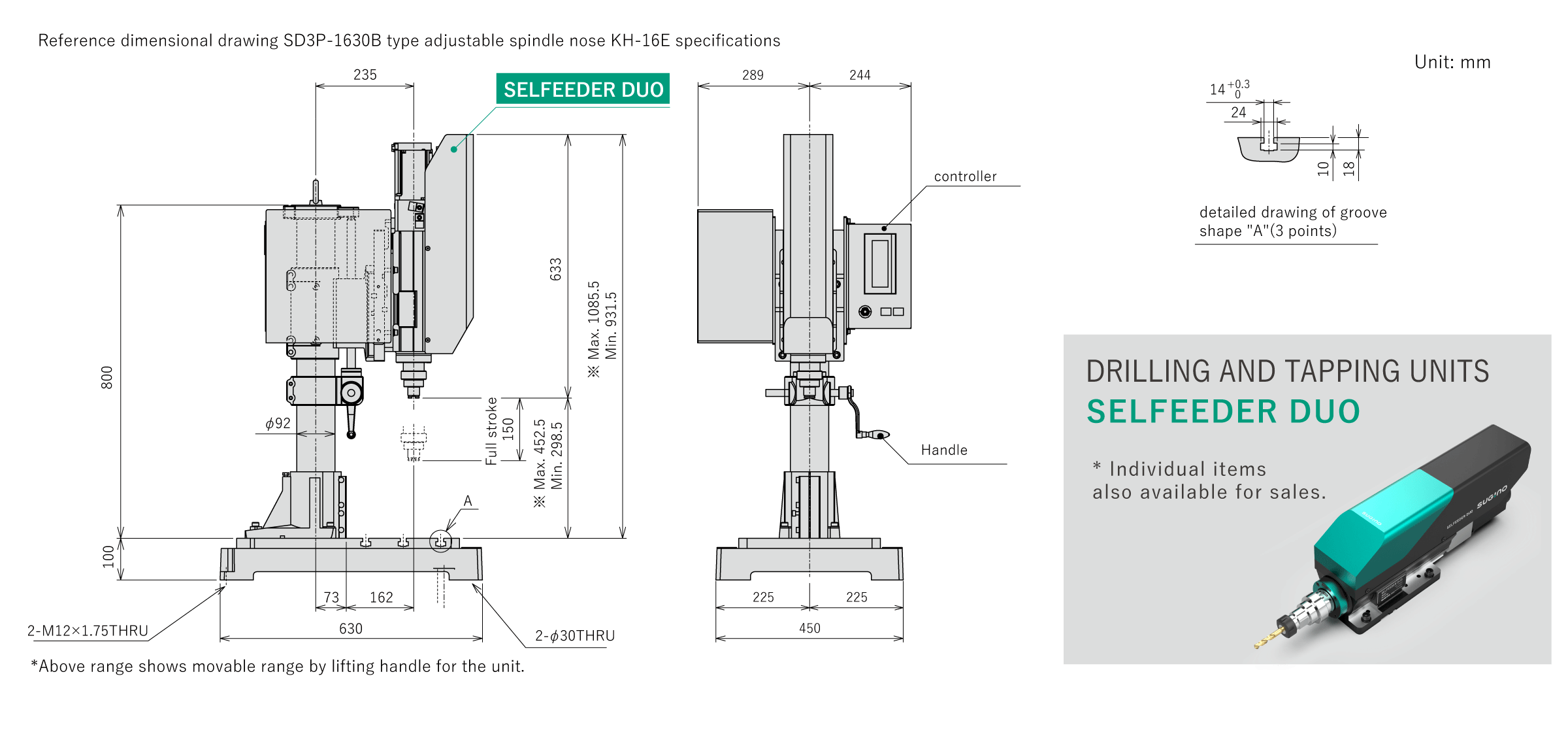

Dimensions