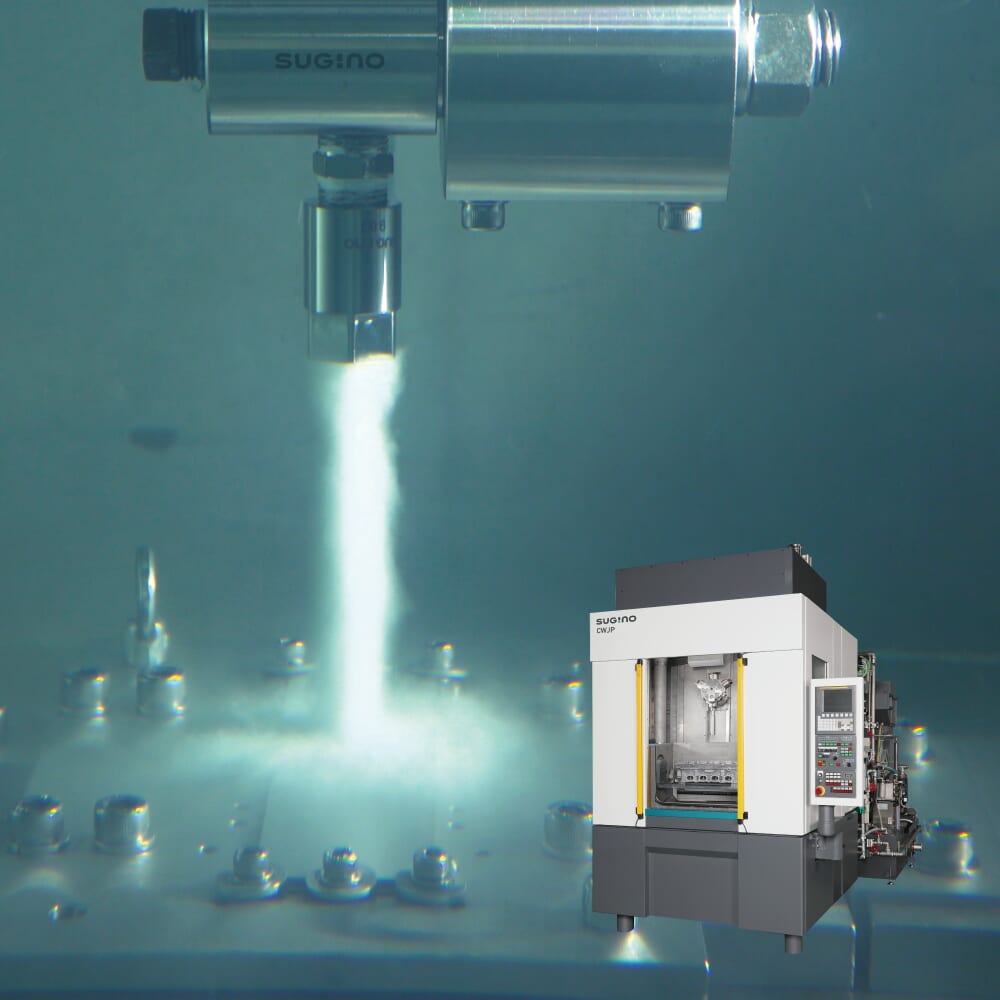

CWJP : Cavitation Water Jet Peening Technology

Cavitation Water Jet Peening CWJP

A shotless, high-pressure water jet technology that improves compressive stress and fatigue life of metal parts.

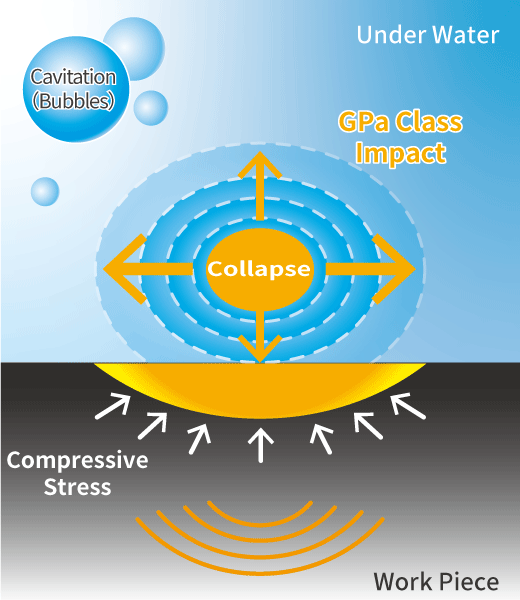

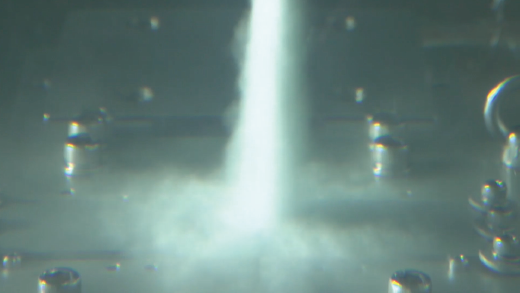

Cavitation is generated by high-pressure water jets underwater with a special cavitation-accelerating nozzle.

When the bubbles collapse near the workpiece, peening effects are achieved with GPa-class impact.

About

Cavitation is generated by high-pressure water jets underwater with a special cavitation-accelerating nozzle.

When the bubbles collapse near the workpiece, peening effects are achieved with GPa-class impact.

Processing Examples

- Prevention of stress corrosion cracking of welds in structures.

- Improve compressive stress of aerospace parts, molding parts, additive manufacturing parts, automotive parts, etc.

Introduction video

Features

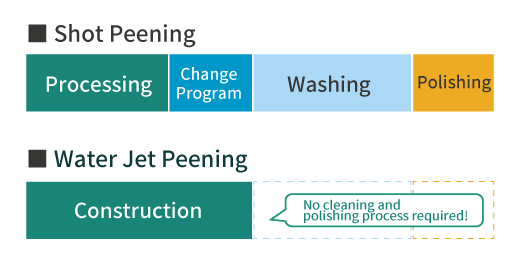

Clean processing method

Shotless peening using only water.

It is a modern clean processing method that generates no industrial waste.

Additionally, since no media is used, washing or polishing in subsequent processes is not required.

The risk of contamination can also be minimized.

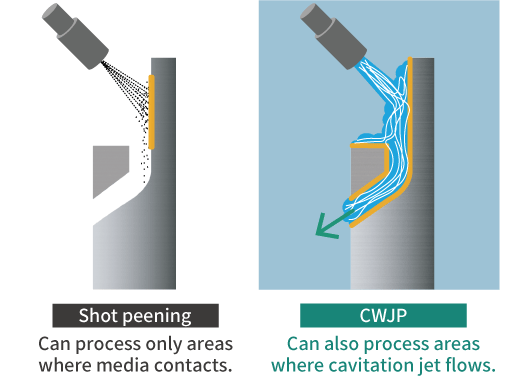

Broad applicable range

Unlike shot peening, which can only be applied to areas where the media makes contact, CWJP can perform peening in the path of the cavitation jet flow.

Furthermore, there is a characteristic that the areas downstream of the cavitation jet flow are more responsive to stress.

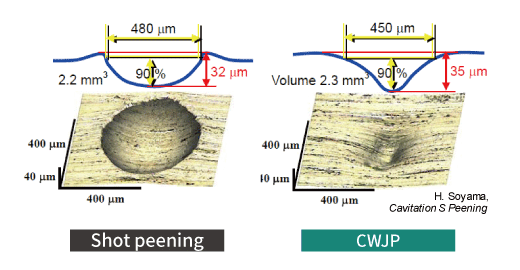

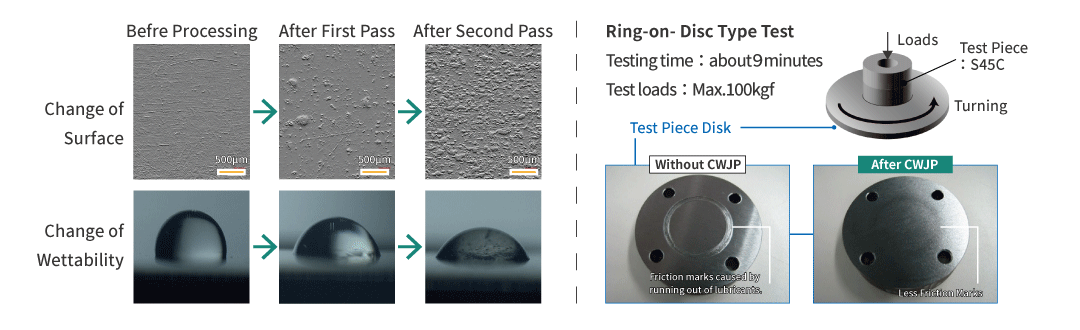

Does not roughen the processed surface.

Peening with water jet can be performed without marring the processed surface.

There is no edge formation on the processed area, allowing for stable extension of the component’s lifespan.

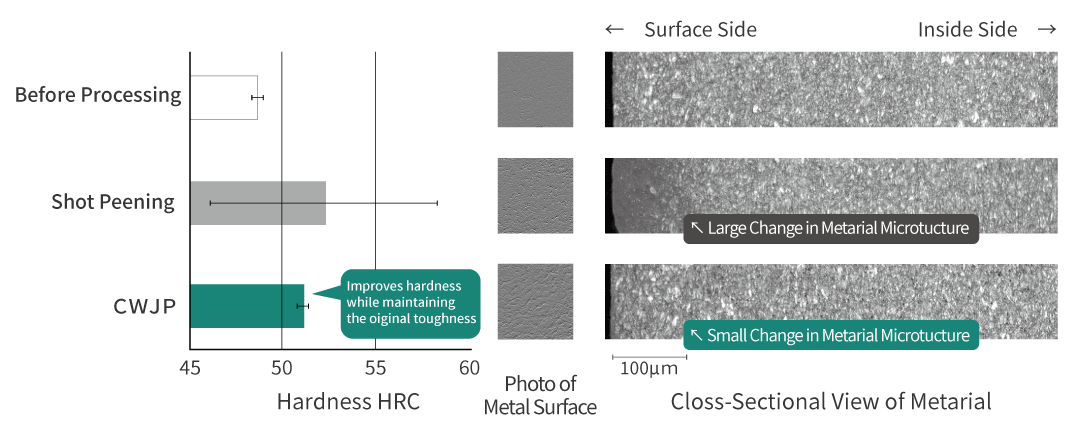

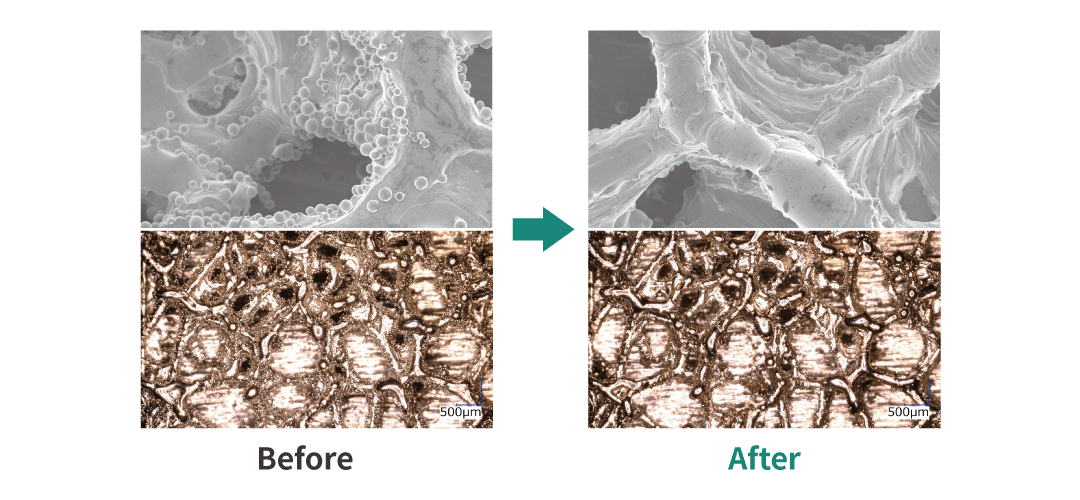

Does not alter toughness

It is a distinctive method that refines and densifies the microstructure, enhancing hardness while maintaining the material’s inherent toughness.

Peening can also be performed on small-diameter components.

Since the cavitation bubbles used for peening are very small, it can be applied to various components, including small-diameter parts.

Traditionally, small-diameter components and intricate areas were limited by media size, but with CWJP, peening is possible.

Effect

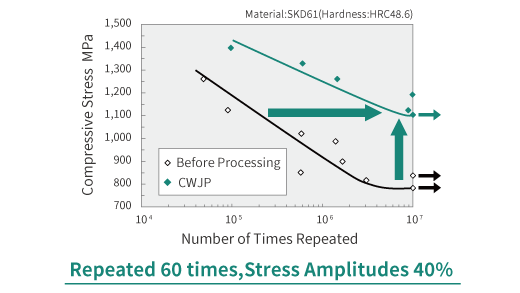

Improved fatigue strength

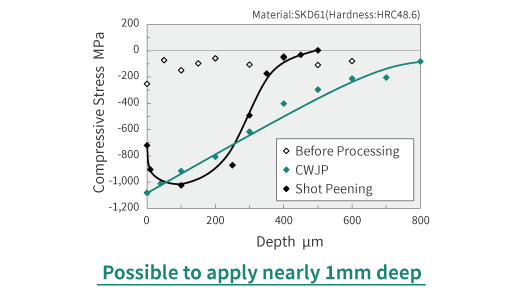

Possible to apply compressive stress nearly 1 mm deep from the surface.

The treatment depth surpasses that of shot peening.

Long lifespan

Possible to improve fatigue strength and fatigue life.

Micro Dimples Formed on the Surface.

Micro dimples become oil pockets and improve sliding

As shown in the figure below, the lubrication performance can be confirmed through ring-on-disk (friction and wear testing).

Removal of un-melted AM powder from 3D additive manufacturing

CWJP processing technology can remove poorly melted powder left behind in additive manufacturing.

CWJP Main Specifications

| Stroke | X750, Y500, Z500 mm |

| Applicable workpiece size | W500 × D500 × H200 mm |

| Controller | FANUC 0i-MF Plus |

| Machine dimensions | W1,600 × D2,700 × H2,500 mm |

| Machine weight | 4,300 kg |

* The supported work sizes are approximate. Larger work pieces may be supported depending on the shape. Please consult with our sales staff first.