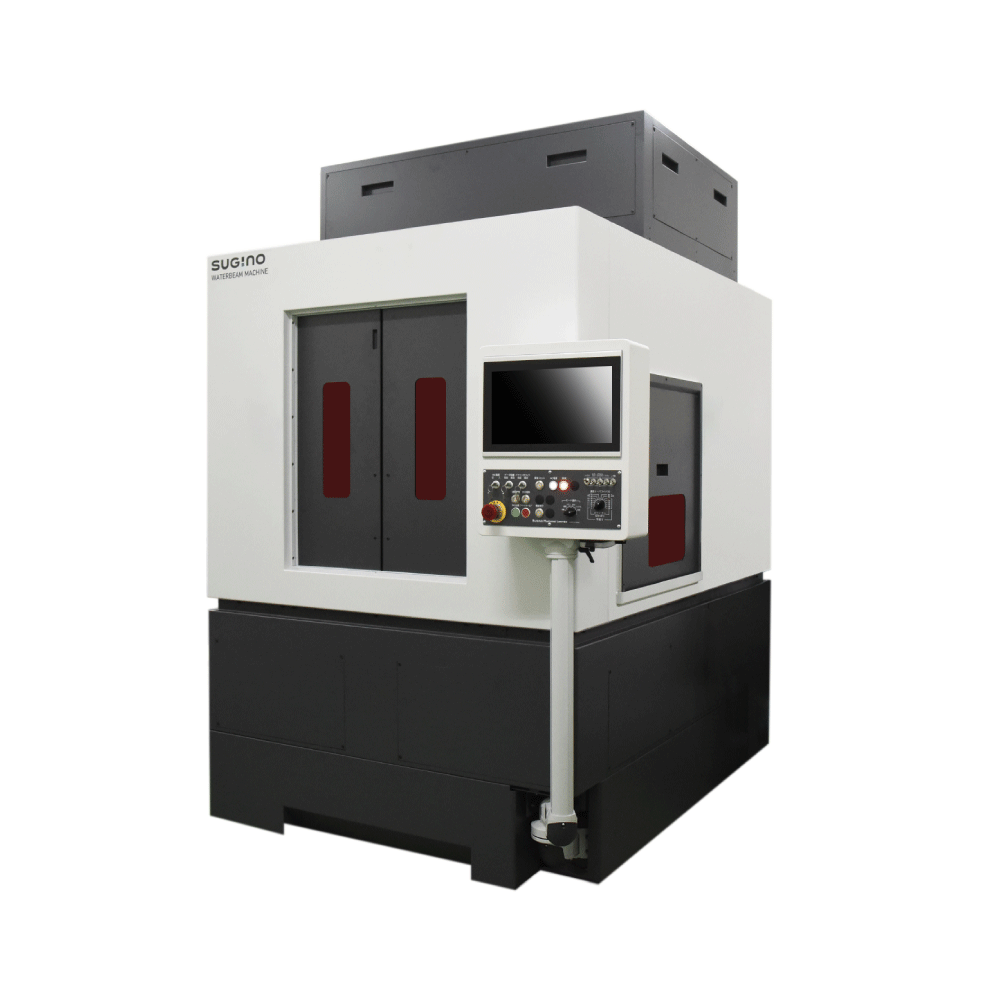

WATERBEAM MACHINE

WATERBEAM MACHINE

The “Waterbeam Machine (WbM)” is a next-generation microfabrication machine that fuses our successful water jet technology together with the latest laser technology.

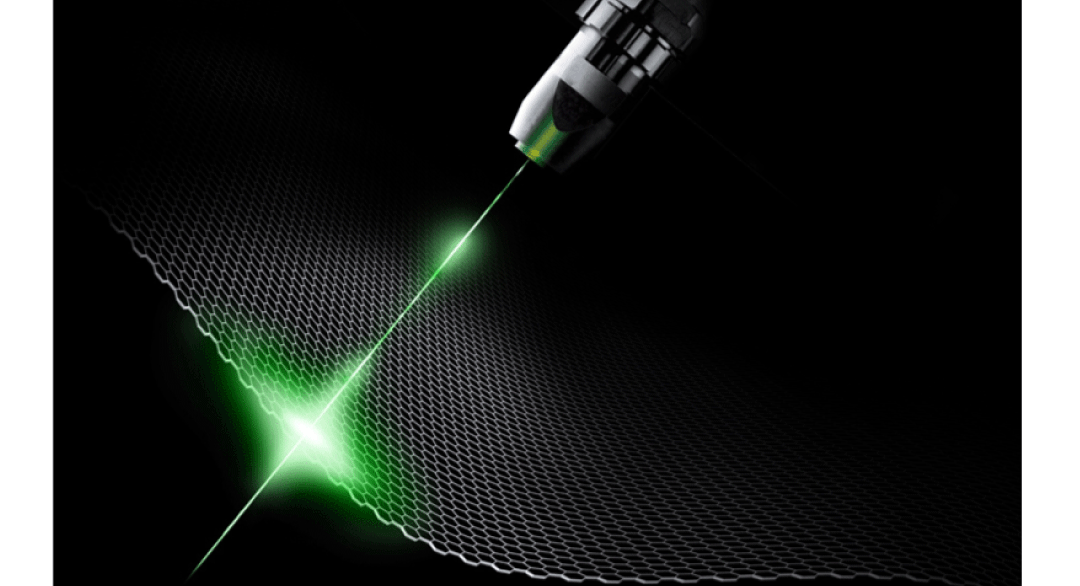

A waterbeam is formed by passing a green laser that is not easily absorbed by water at high speed inside a water jet sprayed from a waterbeam nozzle with a diameter of several tens of micrometers during repeated total reflections.

When the waterbeam collides with the workpiece, the laser is initially absorbed by the workpiece, generates heat, melts the workpiece, and then it is cooled by the water jets. At the same time, residue is washed away by the water jets.

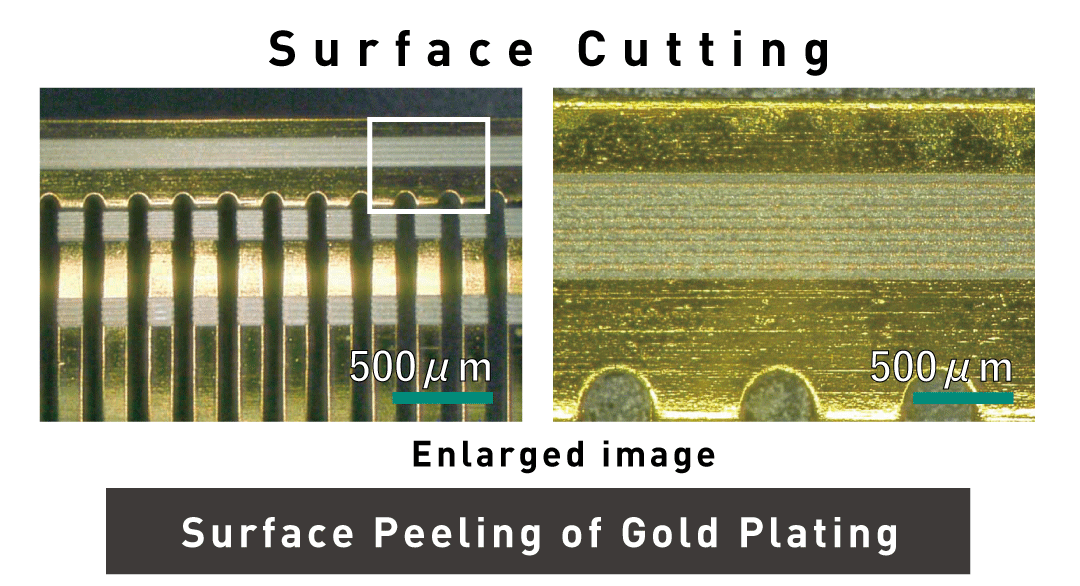

Clean cuts, grooving, and surface processing are possible with an extremely small heat effect.

Features

- Small heat damage and less burrs

Drop in fracture strength and oxidation of workpiece can be reduced. - No focal length restrictions

Because there are no focal length restrictions, the waterbeam can reach the bottom of even thick workpieces. - Supports a wide range of material

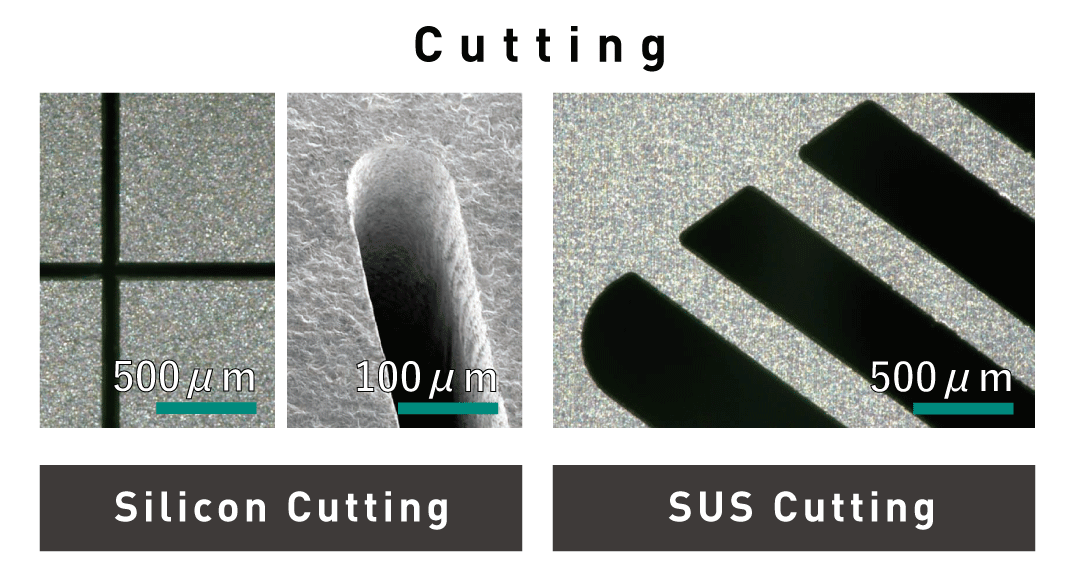

It can process semiconductor materials (Si, GaAs, SiC), metals (stainless steel,

shape memory alloy), ceramics (alumina, low-temperature sintering

substrate) and other materials. - Implementation of high-precision microfabrication

High-precision microfabrication is possible by using an ultrafine waterbeam of a diameter of 10 μm or less and high-functioning drive system.

Application Examples

Medical equipment manufacturers

… Microfabrication of SUS materialSemiconductor material parts manufacturers

… Microfabrication of silicon wafer

… Scribing

… Shaping of hardened materialAutomotive parts manufacturers

… Micro drilling of hardened materials