Jet Storm Washer P-type: Aeration Jet Type Washing Machine

JET STORM WASHER-P

The “Jet Storm Washer P-type” is an aeration jet type washing machine capable of automatically performing all processes from washing, degreasing, air blow, and hot-air drying.

It offers a reduction in energy consumption, improvement in quality, and a reduction in the environment load during washing of various types of workpieces from wide-ranging industries.

Video

Features

- The compact main unit contains a large washing tank

Even at a width of 850 mm, the washing machine is provided with a 65-L washing tank which can be used to simultaneously wash several irregular-shape workpieces. - High-power washing and degreasing performance

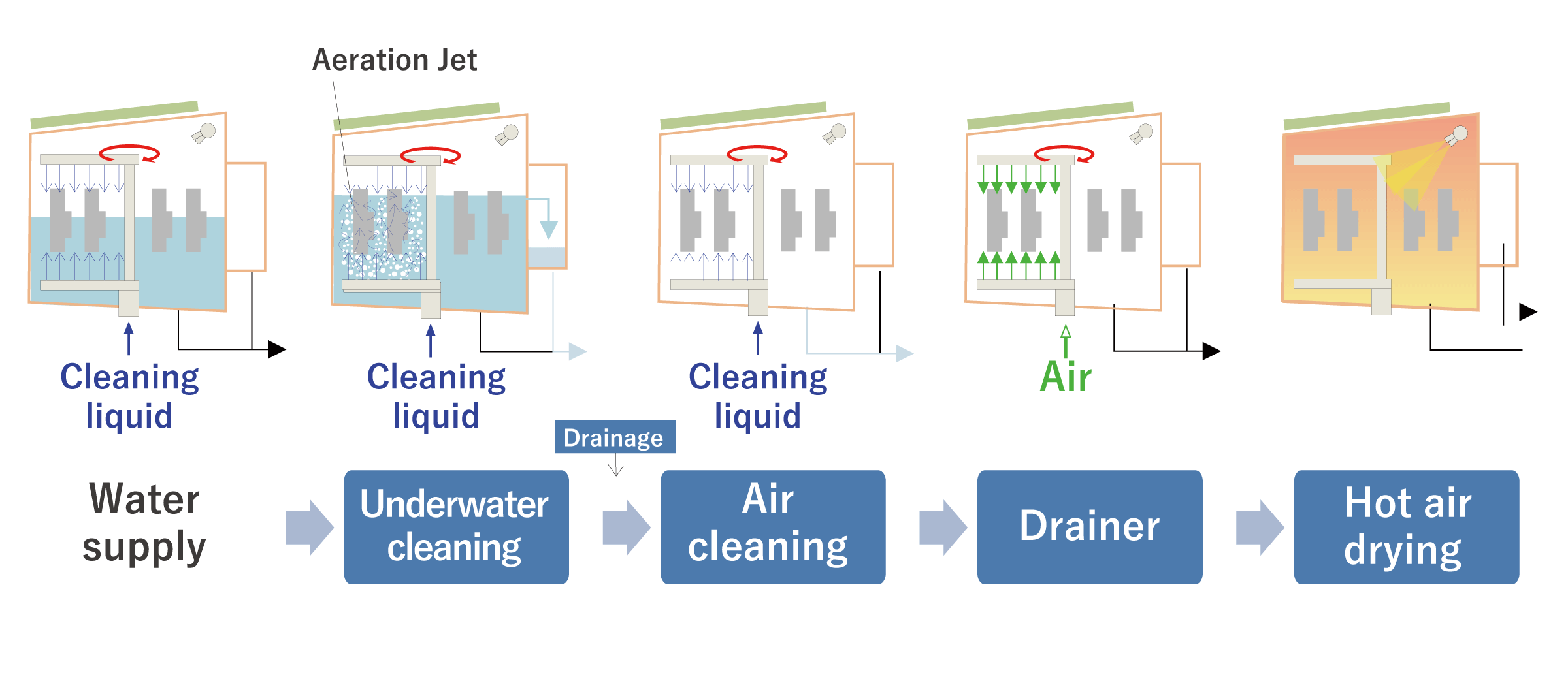

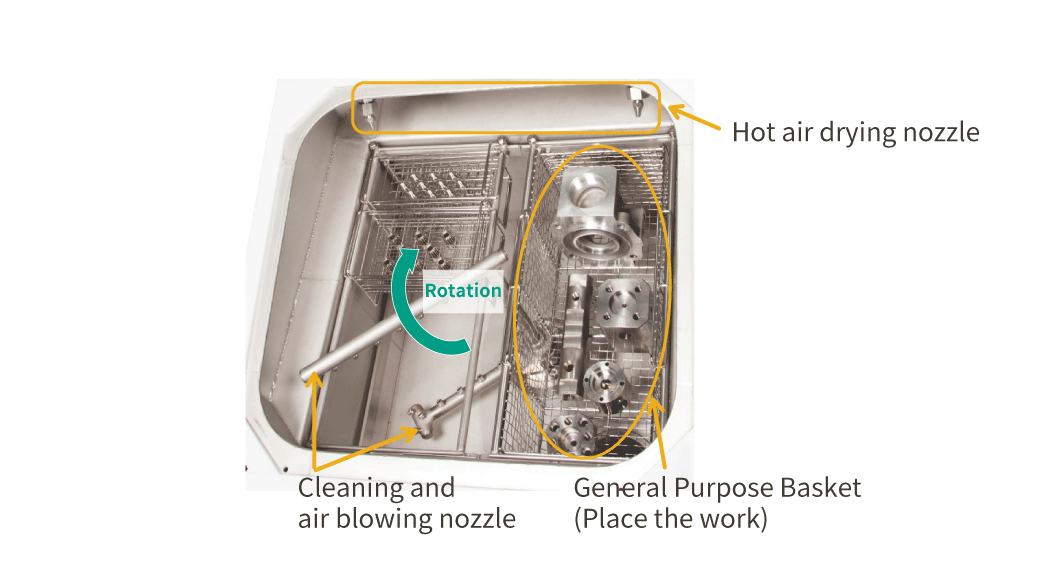

Because of the upper and lower, two systems of rotating nozzle and the swirling flow, even workpieces with a complex shape can be washed without leaving any blind spots. As a result of the aeration jet and heating, high power degreasing and removal of impurities is achieved without the use of an organic solvent. - Fully Automatic Processes from Washing to Drying

All processes from submerged and open-air washing to drain by air blowing, and hot-air drying are performed automatically. Products are dried immediately after washing without going through human hands, which prevents the occurrence of rust and water marks.

Features

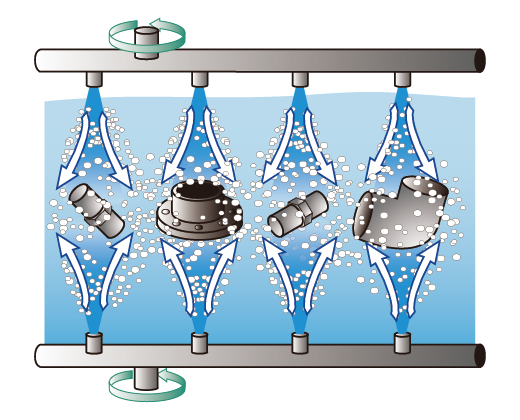

1. The underwater aeration jet provides powerful cleaning even inside parts!

An aeration jet is a jet stream containing air bubbles. The aeration jet emitted from a rotating nozzle reaches every hole and inside the workpiece, pulling away dirt and oil. The force of the aeration jet emitted from both above and below thoroughly removes dirt even from the inside of parts with complex shapes.

2. This one machine can do everything from washing to drying!

The two upper and lower rotating nozzles and swirling flow allow for cleaning of complex shaped workpieces without any blind spots. The aeration jet and heating effects enable powerful cleaning and foreign matter removal without the use of organic solvents. In addition, the process can be fully automated, from cleaning in water and air to draining with air blowing and hot air drying. Drying can be performed immediately after cleaning without manual intervention.

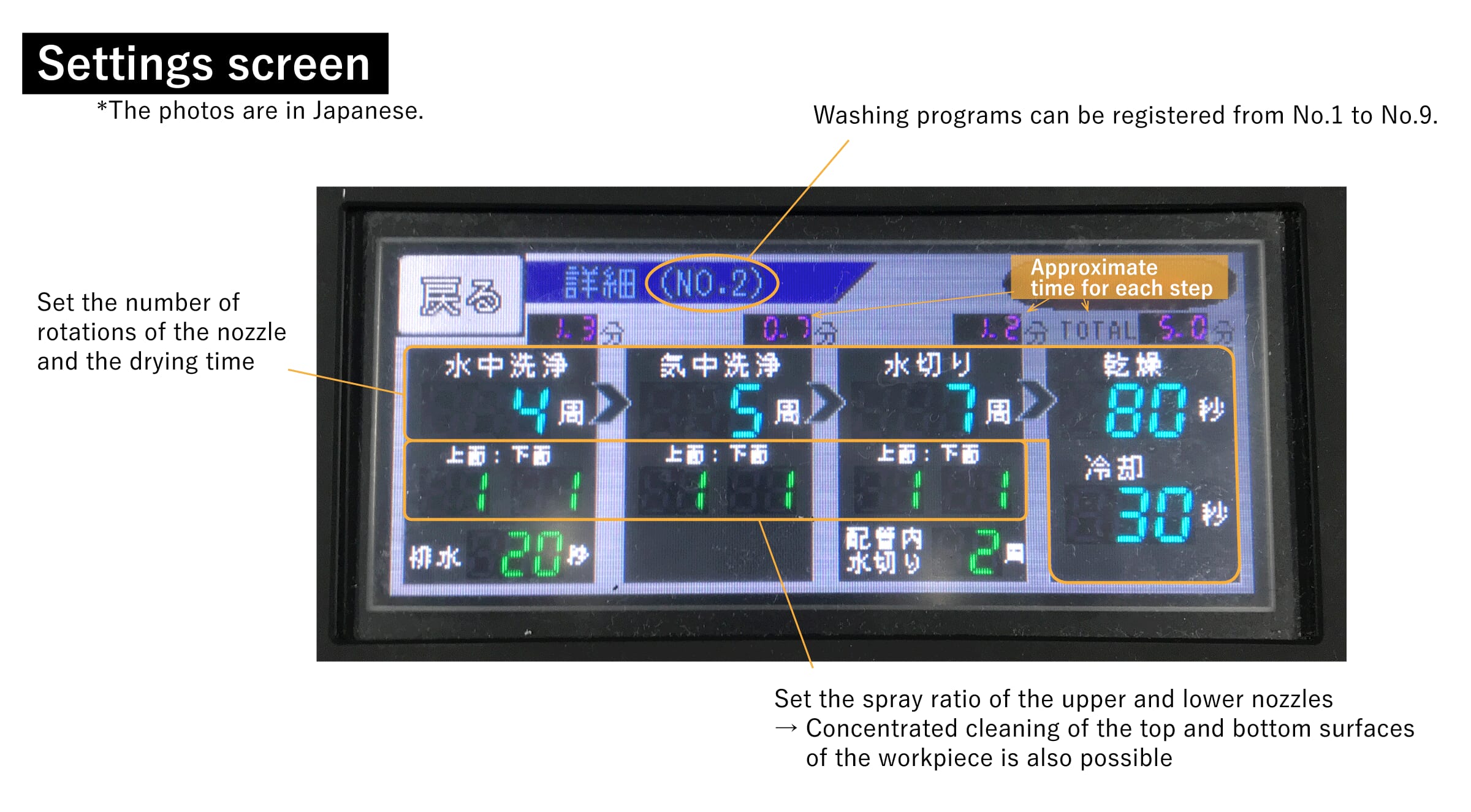

3. Detailed settings can be achieved with simple operations!

Setting washing conditions is simple, just enter values into the touch panel, so anyone can use it easily. In addition, up to nine washing conditions can be saved, so you can simply select a saved condition and press the operation button to complete washing and drying of the workpieces.

4. Compact design, smaller than one tatami mat

The device itself is compact, measuring just 850mm wide and 1,450mm deep, and fits within the space of a single tatami mat. It is effective even in limited installation spaces.

Specifications

| Model | JSW-P08N | |

|---|---|---|

| Washing spec. | Cleaning Method | Aeration jet + nozzle rotation |

| Pressure x Flow Rate | 0.8MPa×60L/min | |

| Cleaning solution | Water-soluble cleaning solution (neutral to weak alkaline) |

|

| Cleaning tank size | W500×D500×H220mm | |

| Washing solution heating | Max.60℃ (Electric heater: 7kW) | |

| Draining method | Air Blow | |

| Drying method | Hot air drying | |

| Machine spec. | Workpiece mounting method |

Basket type (General-purpose basket inner dimensions: W185xL445xH151mm) |

| Machine Dimensions | W850×D1,450×H1,150mm | |

| Weight | 450kg | |

| Tank Capacity | 150L | |

| Ancillary Facilities | Cleaning pump, line filter, oil skimmer, level gauge, pressure switch, casters, etc. | |

| Power spec. | Three-phase AC200V 50/60Hz | |

| Power supply capacity | Max. 14kVA (unheated: 8kVA) | |

| Utilities | Compressed air, industrial water | |

| Option | Baskets, magnetic separators, signal towers, etc. | |

Names of each part

Basket

By using a special basket that matches the shape of the workpiece, contact between the workpieces is prevented.

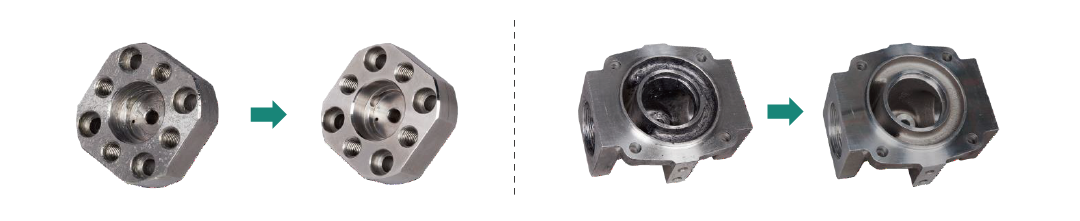

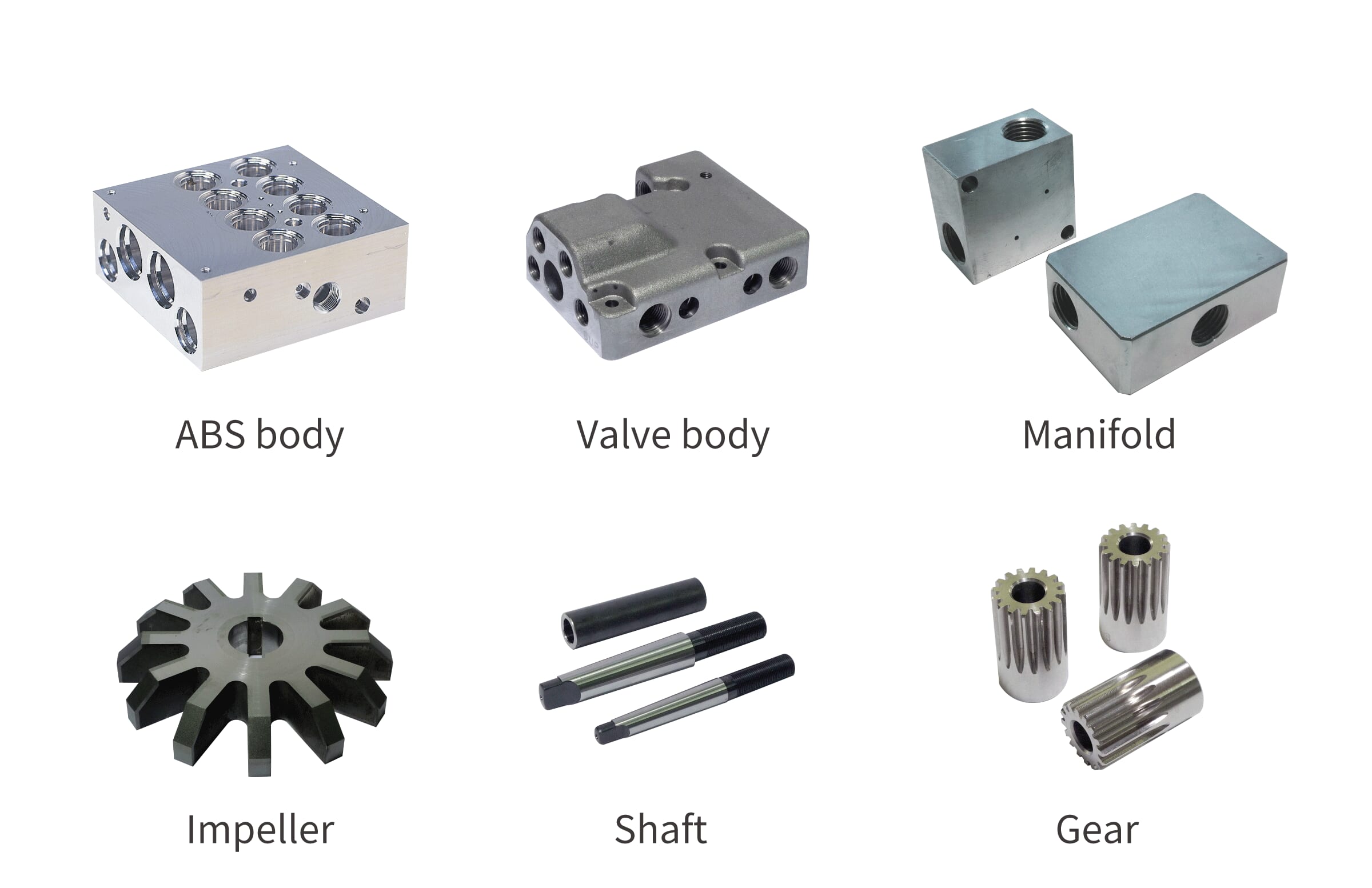

Application Examples

Washing and drying of all machine parts

Implementation track record (examples)

Cleaning Examples