DRY BURST DB-100S CE: Twin Impeller Counter Current for Small Scale Production Dry-type Milling Equipment

DRY BURST DB-100S

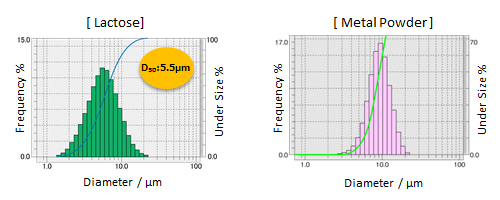

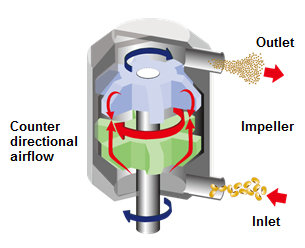

The “Dry Burst DB-100S CE” is a space-saving dry-type milling device that supports continuous production of low-contamination powder with a particle diameter of less than 10 µm. The powder is produced by colliding the raw material particles with one another using the air flow generated by two rotating impellers.

Compared with jet mills, the particle diameter can be better adjusted without over-pulverization.

Furthermore, the running costs are lower since the unit’s power consumption is low.

Features

- High pulverization capability

The unit’s counter air flow enables micron-order pulverization, while also producing a sharp particle size distribution. - Low thermal effect

The unit comes with a standard water jacket and an air classification that helps to minimize the thermal effect. - Highly maintainable

The pulverization compartment can be opened without the use of any tools, making access easy during maintenance work./li> - High reliability

The unit makes use of our proven high-precision mechatronics and know-how in atomization technology.

Pulverization Mechanism

Superior Cleaning and Maintainability

Specifications

| Max. rotation speed | rev/min | 20,000 | |

| Processing capacity | kg/hr | ~4 (differs depending on materials and particle size) | |

| Main Body | Dimensions (W × D × H) | mm | 535 × 410 × 480 |

| Weight | kg | 50 | |

| Power supply | – | Single phase 230 V 2.2 kVA | |

Application Examples

- Inorganic materials (electronic parts materials, etc.)

- Organic materials (pharmaceutical raw materials, food, and biomass)

- Wet materials, etc.

Pulverization Data