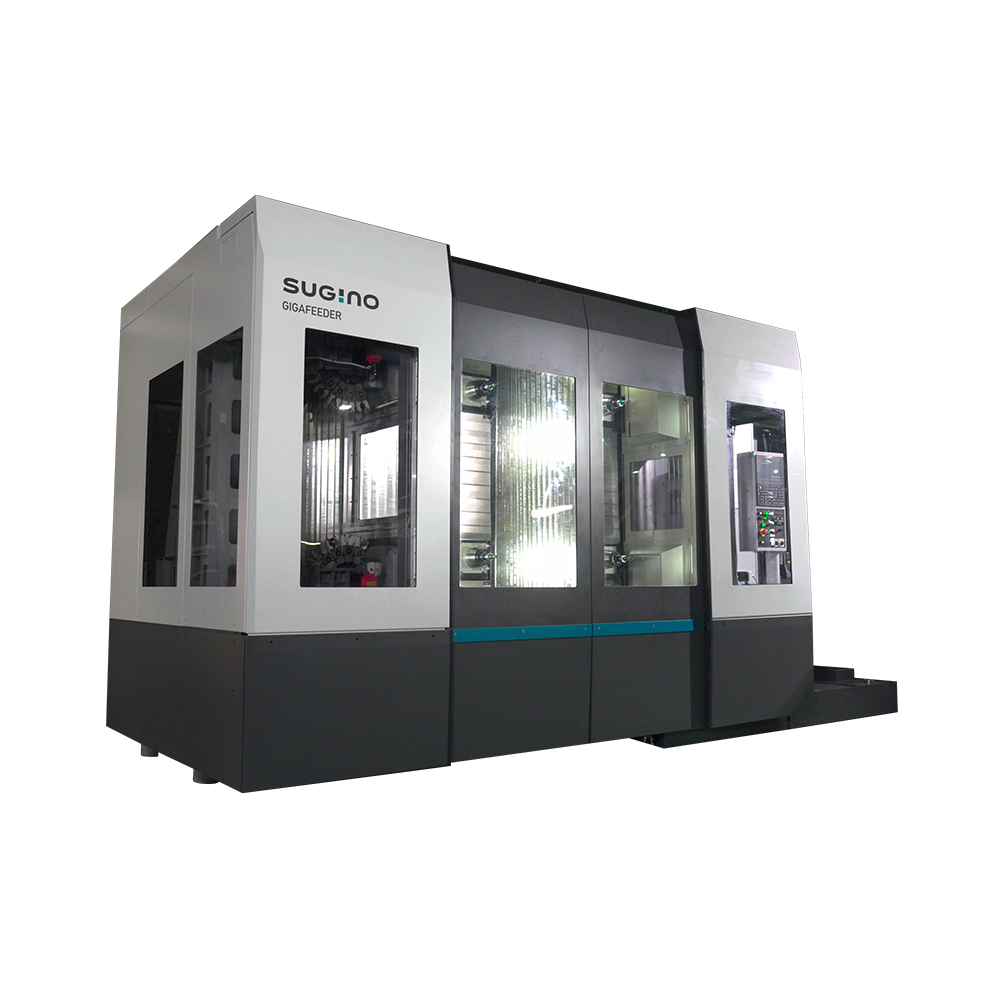

GIGAFEEDER: Large size part processing machine

GIGAFEEDER

GIGAFEEDER is a large size part processing machine that has evolved the usability of the renowned drilling and tapping unit ‘SELFEEDER’.

It features a large stroke moving axis and an added ATC function, enhancing its versatility. It also incorporates the machine rigidity and machining performance developed from the #30 machining center, achieving superior cutting performance.

Here’s a recommendation for customers with these concerns!

For those who need extensive machining but only require light cutting and haven’t found the perfect machine.

- In the trend toward electric vehicles (EVs), there is a growing demand for lightweight components, leading to an increase in the use of aluminum die casting for vehicle body structures.

- The machining precision required for vehicle body structure components is not very stringent.

- While the focus is on light cutting, drilling, and tapping, there are still few dedicated machining facilities due to the novelty of the new components.

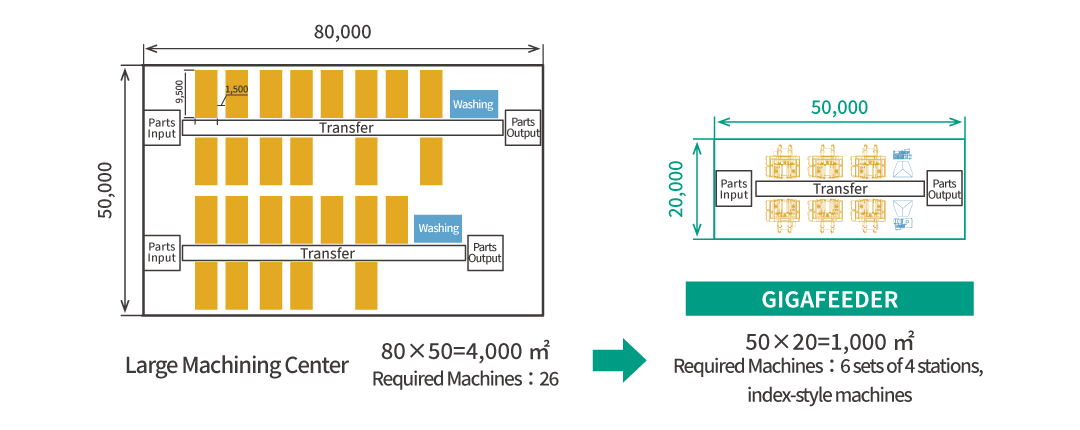

Machining EV components takes up a significant amount of factory space due to the large size of the equipment.

- As component sizes increase, the machining equipment itself also becomes larger.

- Compared to conventional lines, the space occupancy in the factory will be significantly larger.

- There is a strong demand for a machine that offers a large machining area while being space-saving.

Product introduction video

Features

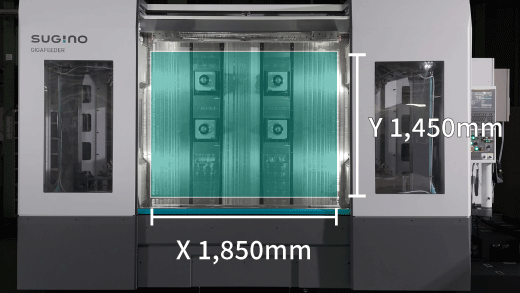

Spacious processing area to accommodate large EV components

The four standard horizontal spindles provide a processing area with X-axis of 1,850mm, Y-axis of 1,450mm, and Z-axis of 350mm, ensuring ample stroke for machining large EV components

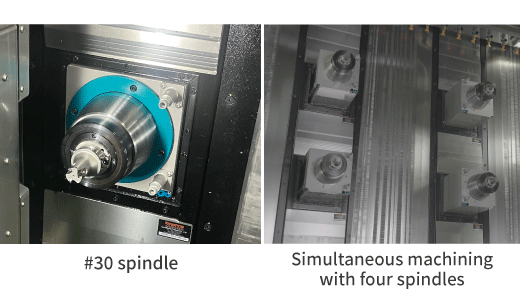

Reduce processing time with simultaneous machining at multiple locations using the #30 spindle.

Each unit (1 module) is equipped with 4 spindles as standard, and can be configured with up to 6 spindles.

Since each spindle operates separately and simultaneously, processing time can be significantly reduced.

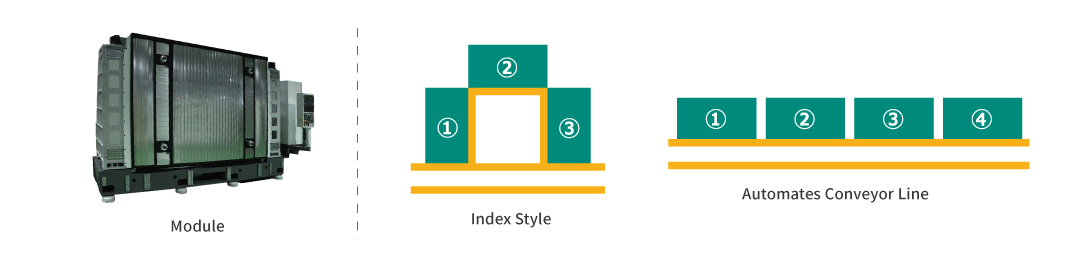

Additionally, by combining multiple modules in an index-style arrangement, even shorter processing times can be achieved.

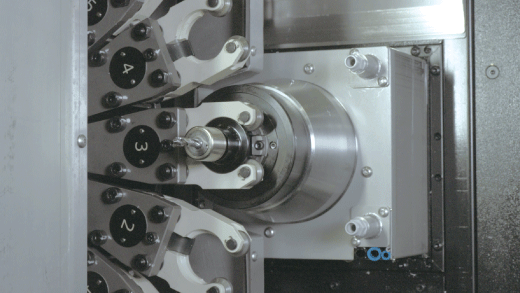

Equipped with ATC for flexible machining

Each spindle comes equipped with an ATC magazine that holds up to 11 tools.

In addition to drilling and tapping, flexible processing such as milling can be performed.

Space-saving design minimizes the production line

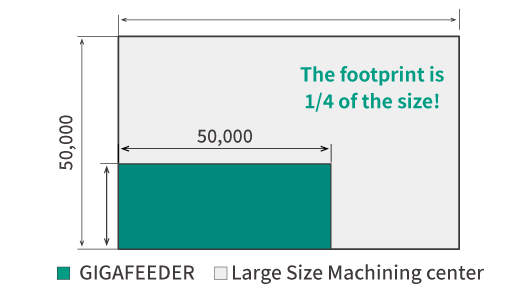

The spindle of the GIGAFEEDER is mounted horizontally, and the workpiece is attached to a tombstone, similar to a horizontal machining center. Compared to gantry-type machining centers or large vertical machining centers with similar machining areas, the footprint is remarkably compact.

Modular design provides customers with the optimal line layout.

GIGAFEEDER features a modular design, allowing it to be configured to meet customer requirements for cycle time, transport systems, and factory layout, providing the optimal production line. Additionally, even if the parts being produced change in the future, the equipment can easily be adapted by reconfiguring the modules, making it highly versatile and flexible for repurposing.

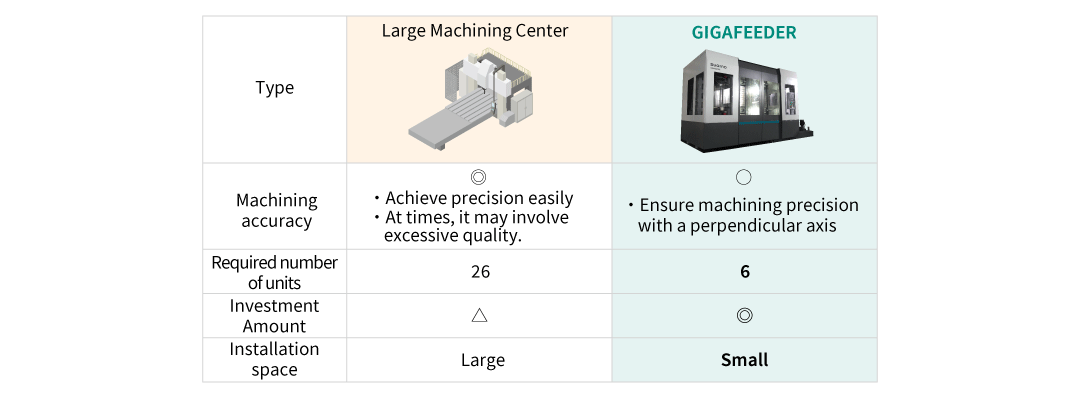

Comparison with Other Methods

Comparison table

While ensuring the necessary and sufficient machining accuracy, you can adopt it with exceptional space-saving and cost-efficiency.

Comparison of Installation Space

Specifications

| Spindle rotation speed | Max. 12,000 min-1 |

|---|---|

| Number of spindles | Maximum 6 (standard 4 <horizontal direction> + optional 2 <vertical direction>) |

| Main shaft taper hole | NT30 |

| Number of tools | 11 each (maximum 66) |

| External dimensions | Width 5,350mm x Depth 2,780mm x Height 2,800mm |

| *Total length of device body excluding coolant tank: 4,100mm | |

| Max, processing area | X-axis 1,850mm, Y-axis 1,450mm, Z-axis 350mm |

| Rapid traverse speed (X, Y, Z axis) | X-axis 60m/min, Y-axis 60m/min, Z-axis 48m/min |

| Processing ability | Drill: 13 drill, tap: M8, milling cutter: φ25 cutter (material: aluminum) |

* Specifications such as dimensions are for reference only and may vary depending on factors such as the number of spindles. Please consult with a sales representative for more details.