STANDRILL SYNCHROTAPPER ST4M : Automatic tapping stand

STANDRILL SYNCHRO TAPPER ST4M

Operational on the same day!

It is a high-precision automatic tapping stand.

Max. tapping capacity ——- Steel M20 / Aluminum M27

Maximum stroke ——- 120mm

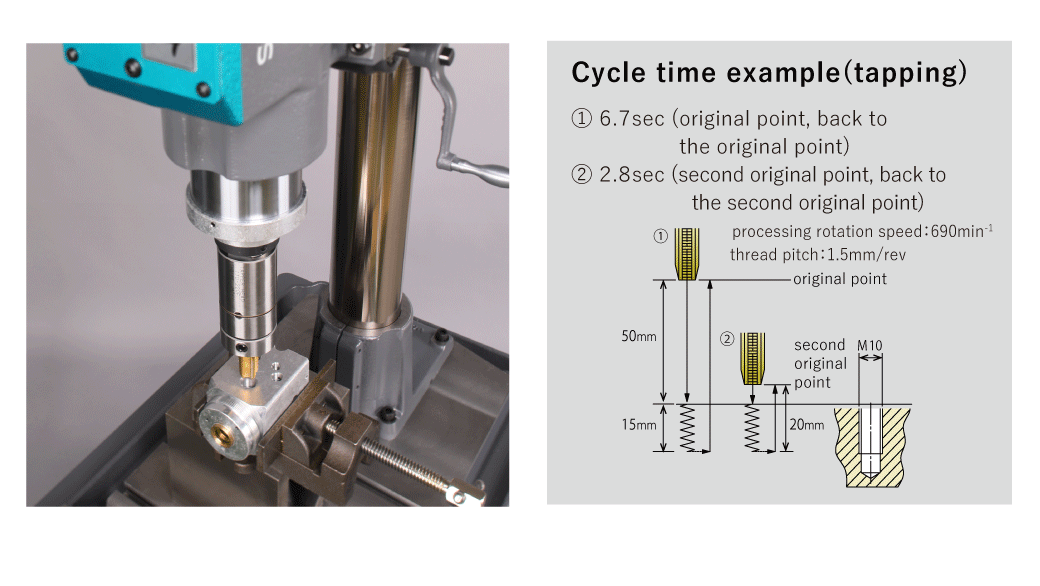

Maximum spindle speed —– 690min-1

Features

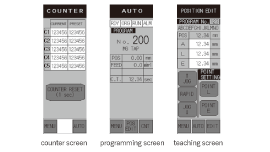

Equipped with a 4.5-inch compact touch panel for manual operation and processing program settings.

No programming knowledge is required; operation is possible with just input for stroke and rotation speed.

Therefore, it is also easy to update from outdated tapping ball screw machines.

Easy operation

Operates on the same day with a 200V power supply

It can be operational from the day of delivery.

Easy programming

We have pre-prepared the processing patterns required for tapping, so you can easily create processing programs by simply inputting the cutting start and end points, as well as the spindle rotation speed at each point.

Abundant functions

Preset counter with 6 digits × 5 units

Program registration capacity: 200 units

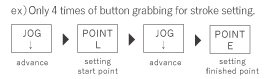

Equipped with a simple teaching function

With the JOG feed and the setting buttons for cutting start and end points, you can intuitively set the stroke.

Customization available

By adding service input/output signals (optional), continuous control of customer-prepared jigs and safety doors is possible.

Labor-saving for various types of nut threading processes

It is possible to easily automate tasks that were previously done manually, such as removing spatter from welded nuts and re-tapping the plating that has adhered to the inner diameter.

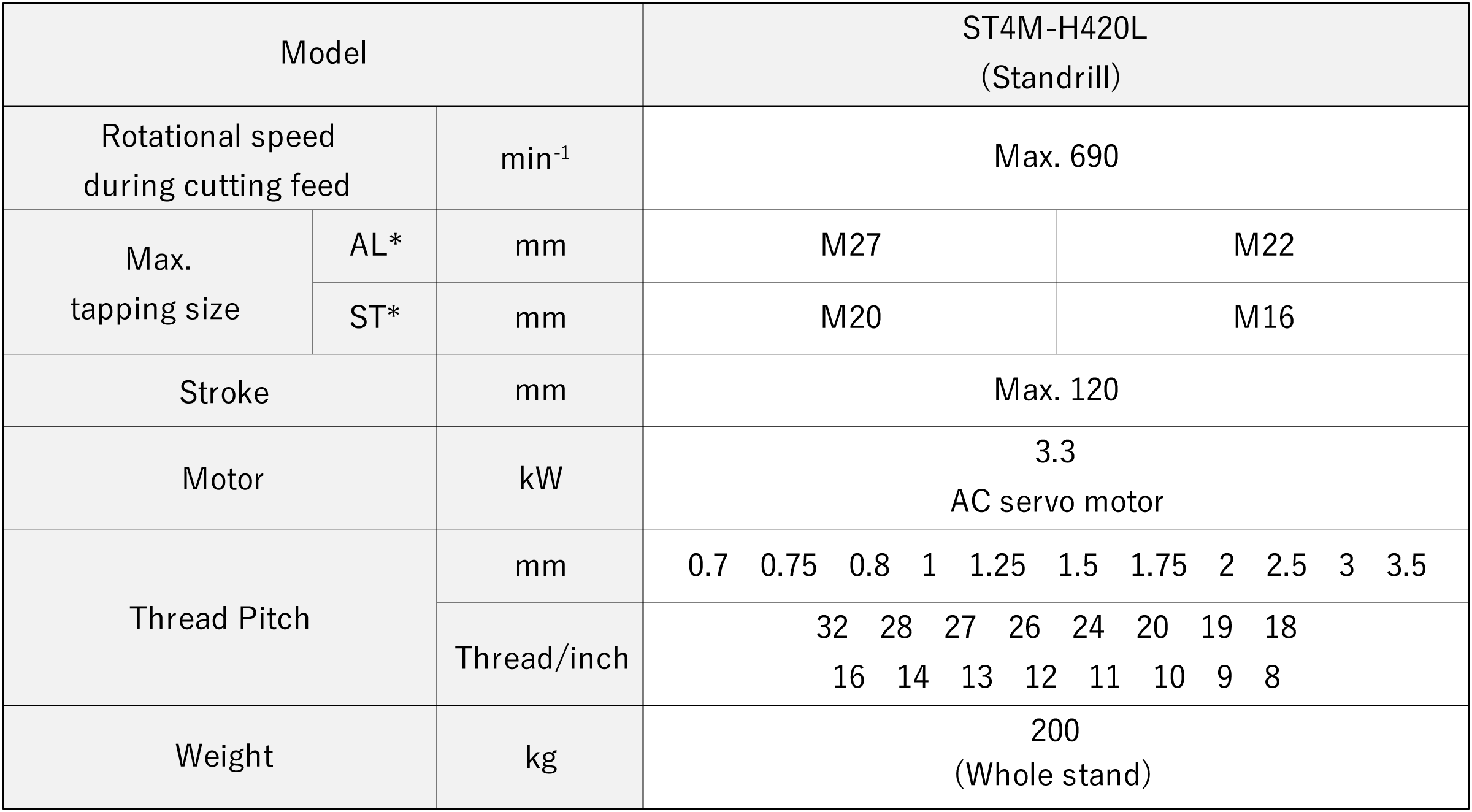

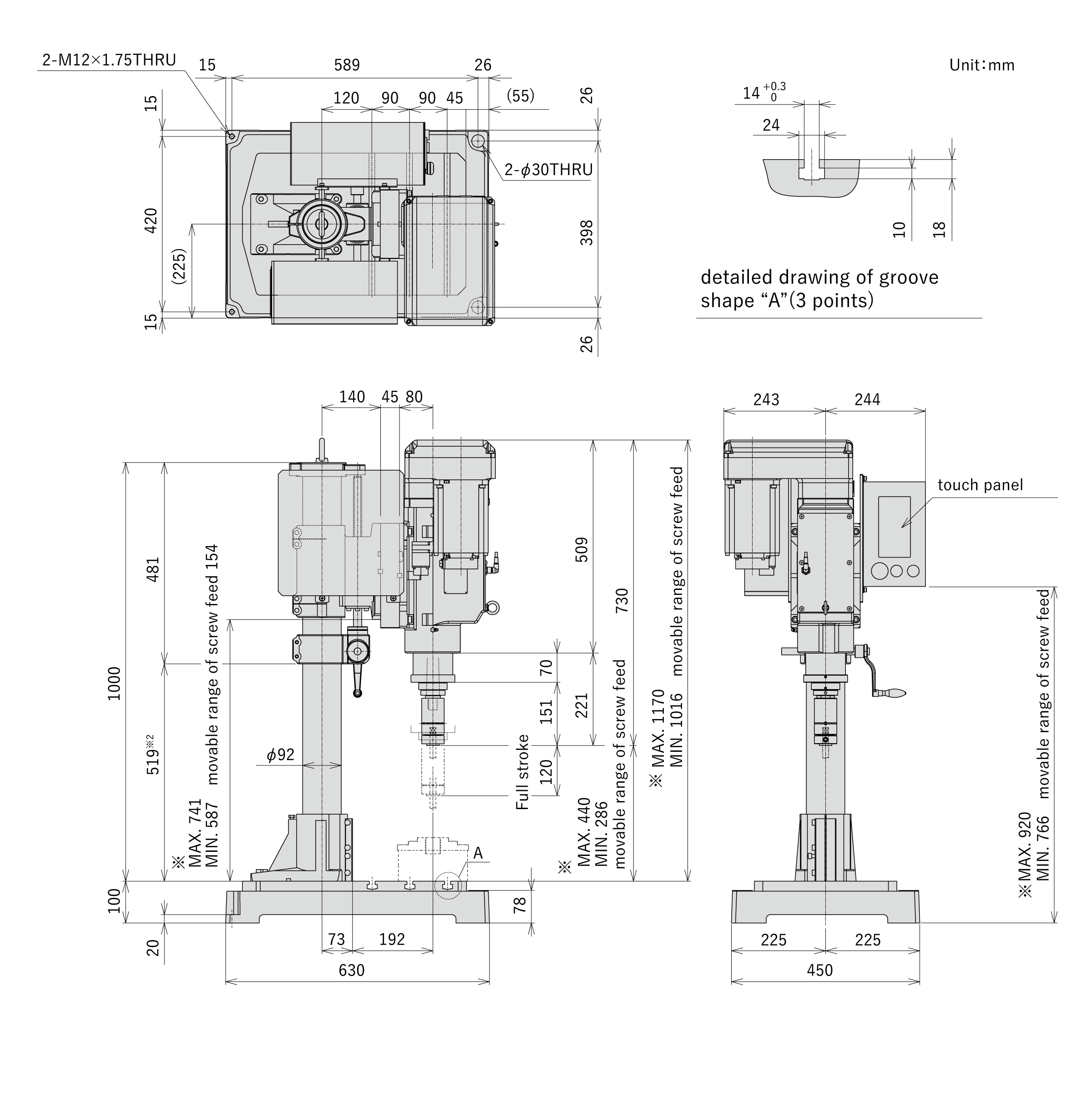

Specifications (Performance Chart & Dimensional Drawing)

Note:

The upper column of the chart is for a spiral tap and a point tap. The lower column is for hand tap No.2. Tapping capacities are conditional on the depth of tapping being limited to 1.5 times of the tap diameter.

Please determine the cutting feed rate and rotational speed based on factors such as workpiece material, machinability, tap diameter, tap material, and cutting speed.

Please specify the pitch of the tap you will be using. Changing the pitch will require replacing the feed gears.”

The rapid feed and cutting feed rate vary depending on the thread pitch and rotation speed.

For more details, please contact the nearest sales office.Depending on the tap size, the single tapper head will come with either the 1TD-220F (with a sleeve for M12 to M22) or the 1TD-160F (with a sleeve for M4 to M16).

*The dimensions are based on the installation of the screw set FS-92SS at the dimensions specified in section 2.

The above illustration shows the single tapper head 1TD-220F. Dimensions will differ when using the 1TD-160F.