SUPER! TECHNOLOGY

SUPER! TECHNOLOGY

SUPER!

TECHNOLOGY

We unlock “SUPER” levels by fine-tuning technology. We consistently deliver surprises and excitement that surpass our customers’ expectations.

We are always adapting to changes, to continually push the “SUPER” boundary.

SUGINO has maintained this stance since the beginning.

We know that a completely different global sight lies ahead beyond the “SUPER” level of technology.

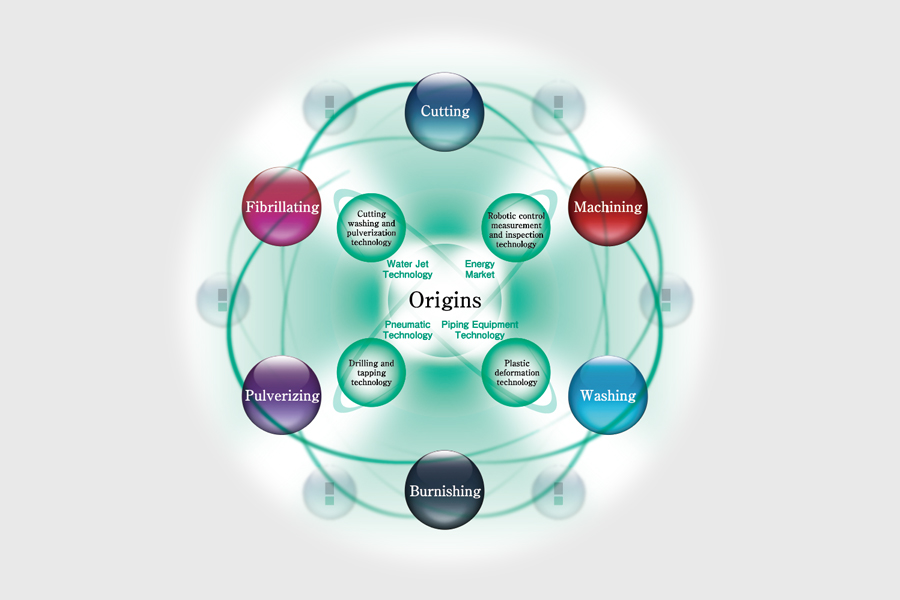

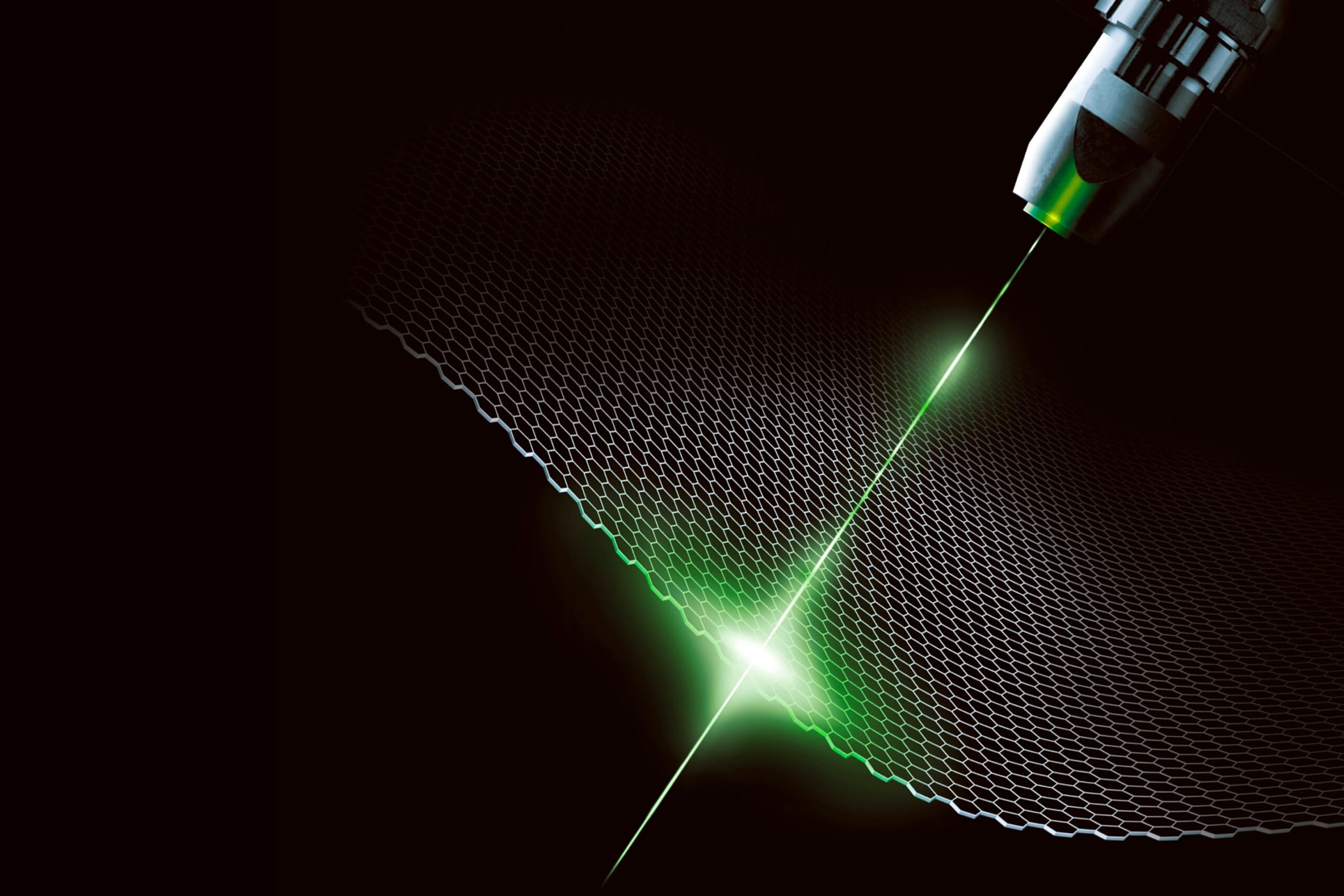

CUTTING

Water is pressurized up to 6,000 atm, and sprayed through a 0.1 mm diameter nozzle.

The energy contained in this high-speed, high-density ultrahigh-pressure water technology is used to cut materials.

The same technology was also used to develop pressure test machines for large storage tanks used by hydrogen stations.

We will use this knowledge to help develop the hydrogen energy societies of the future

Field

- Cars Interior and exterior trimming

- Energy Pressure testing of large storage

- Aircrafts Cutting special materials

- Food Cutting foods, pressurization disinfection, etc.

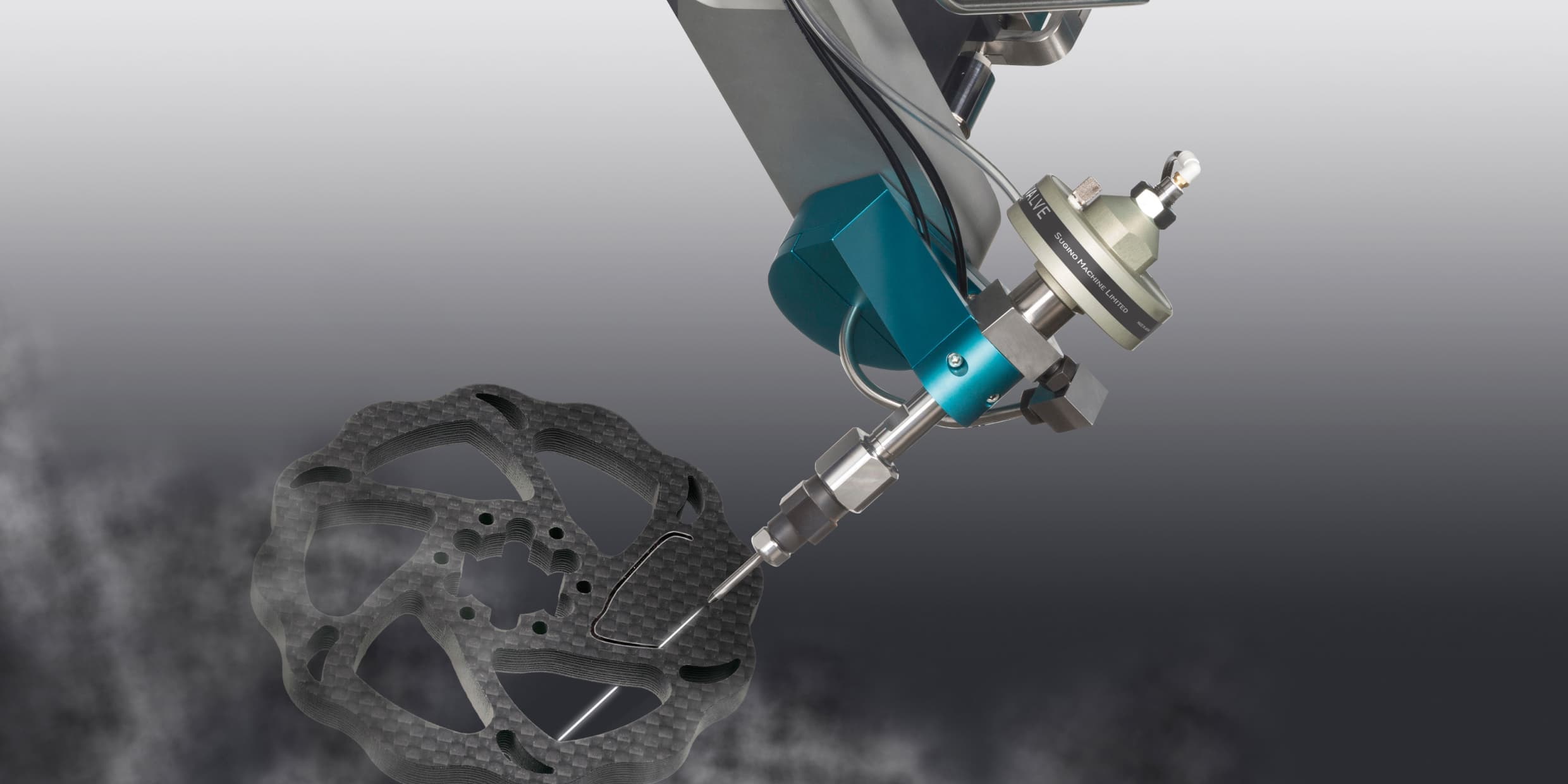

MACHINING

Extensive cutting and machining advancements using pneumatic, water pressure, and electric drive sources, have been developed from our core technology.

From drilling and tapping units to 5-axis control machining centers and combined machines, we provide customers with the optimum solution from our broad product lineup.

Field

- Cars Precision machining of engine and AT parts

- Construction machinery Precision machining of hydraulic parts, etc.

WASHING

Water that is pressurized up to 500 atm washes and removes burrs and cutting chips from various parts.

SUGINO is the only company in the world that manufactures high-pressure pumps and washing machines in-house.

This technology is also used for urban, infrastructure, and other development projects by pressurizing water up to 2,000 atm to remove deteriorated concrete from bridges, pylons, and other structures.

Field

- Cars Precision washing of engine and transmission parts

- Shipbuilding Washing ship hulls and boilers

- Steel Washing of descaling and coking facilities

- Engineering Chipping and peeling concrete structures

- Plants Washing of condensers, heat exchangers and pipes, etc.

BURNISHING

Roller burnishing uses one or more rollers to apply pressure to a metal surface to achieve a smooth finish.

The process displaces the metal through pressure, resulting in an end-product with enhanced residual stress, increased abrasion resistance, and improved fatigue strength.

Field

- Cars Surface improvement of pistons, valve bodies and other parts

- Construction machinery Internal cutting and finishing processing of hydraulic cylinders

- Plants Expansion of heat exchanger tubes, etc.

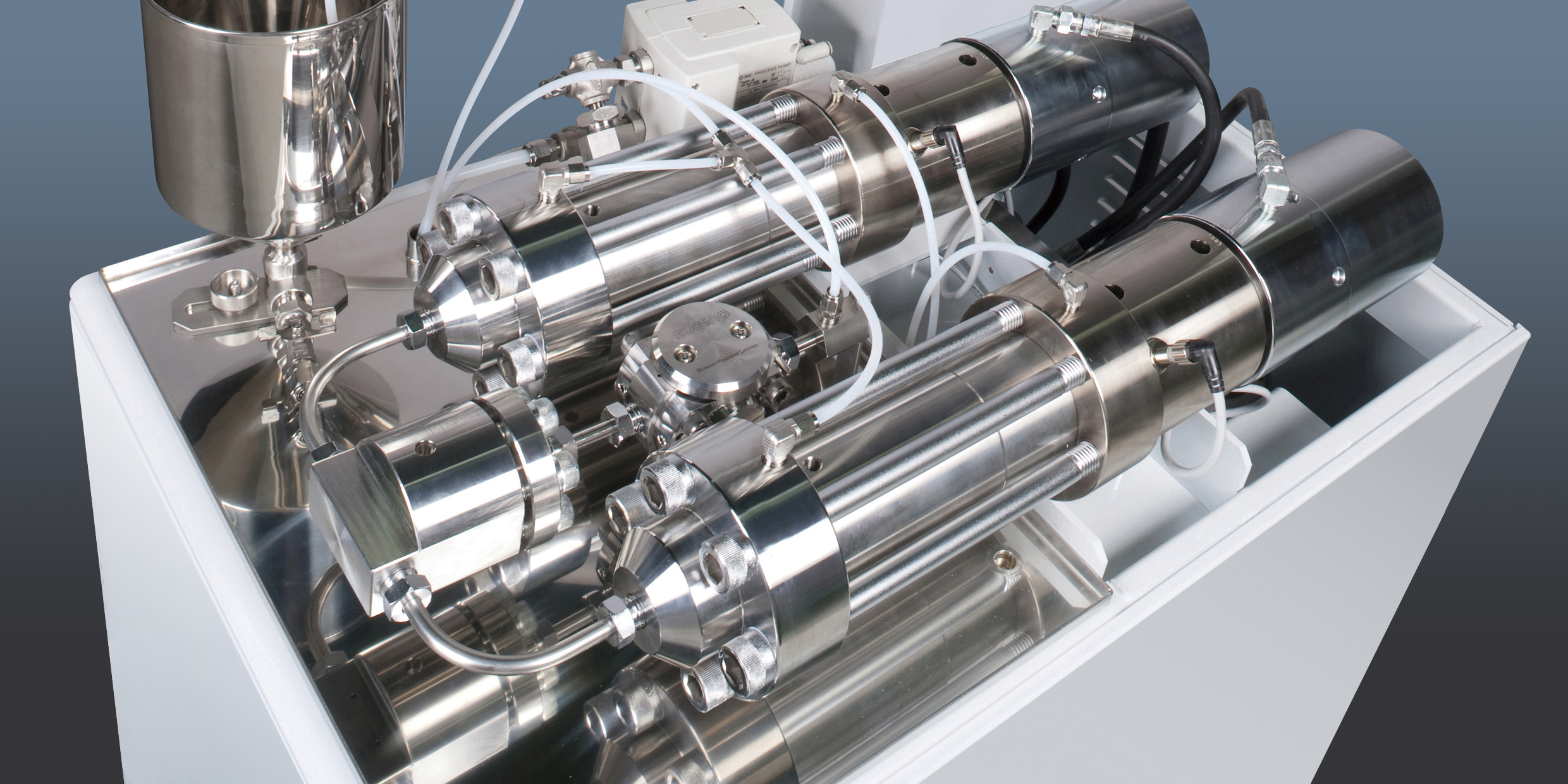

PULVERIZING

Making materials smaller increases their available surface energy ratio. It also changes or enhances a material’s properties to maximize its benefits.

SUGINO’s atomization technology developed from water jets allows tiny particles to be manufactured, free of impurities, ideal for industries that require an ultra-clean environment, such as cosmetics, pharmaceuticals, and electronics.

Field

- Cosmetics Atomization of lotions and UV protectants

- Pharmaceuticals Atomization of injection drugs and ribosome

- Electronic parts Atomization of battery materials, CMP slurries

- Pigments Atomization of toners and printer ink

- Food Atomization of spices and antioxidants, pulverization of uncooked rice and tea, etc.

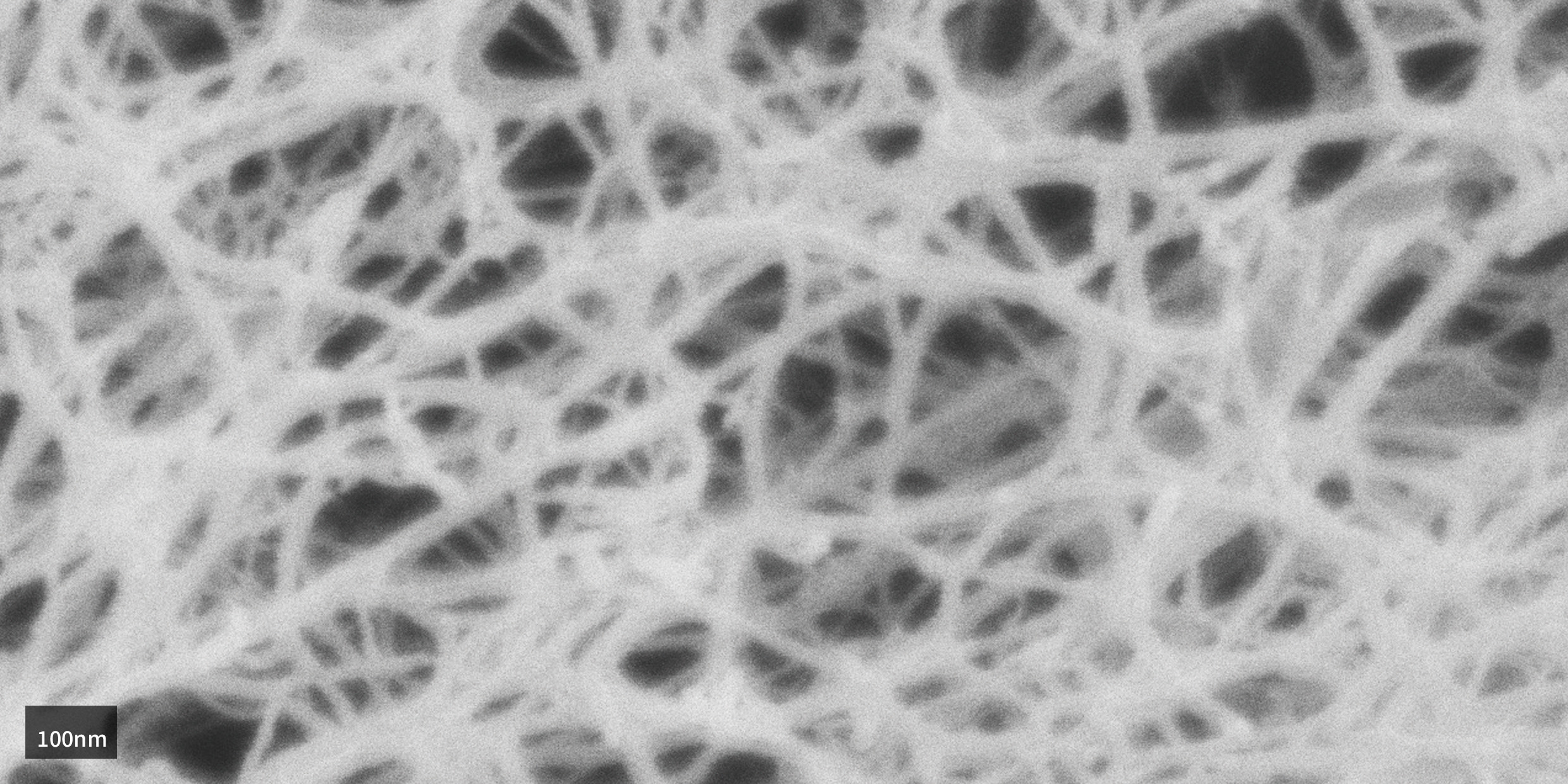

FIBRILLATING

Ultra-fine biomass nanofibers are produced by ultra-high-pressure water jet technology.

They are made from biomass fibers of cellulose, chitin, chitosan, and silk, with an average size of 10-50 nm wide and several µm long.

Biomass nanofibers have low linear thermal expansion, effect elasticity, transparency, biocompatibility, antibacterial features, improvement of physiological functions, high strength, high aspect ratio, high specific surface area, high viscosity, high shape retention, and high hydrophilicity with applications across a variety of fields.

Field

- Chemicals Resin reinforcing materials, transparent base materials, filters

- Electronics Electrode materials, auxiliary conductive materials

- Fibers Reinforcing materials, binding agents, absorbents

- Cosmetics Base materials, moisturizers, sunscreen

- Food Performance substances, thickeners, moisturizers and fillers

- Pharmaceutical Biologically compatible materials, filming agents, hemostatic agents

- Construction materials Multi-functional construction and internal materials, etc.