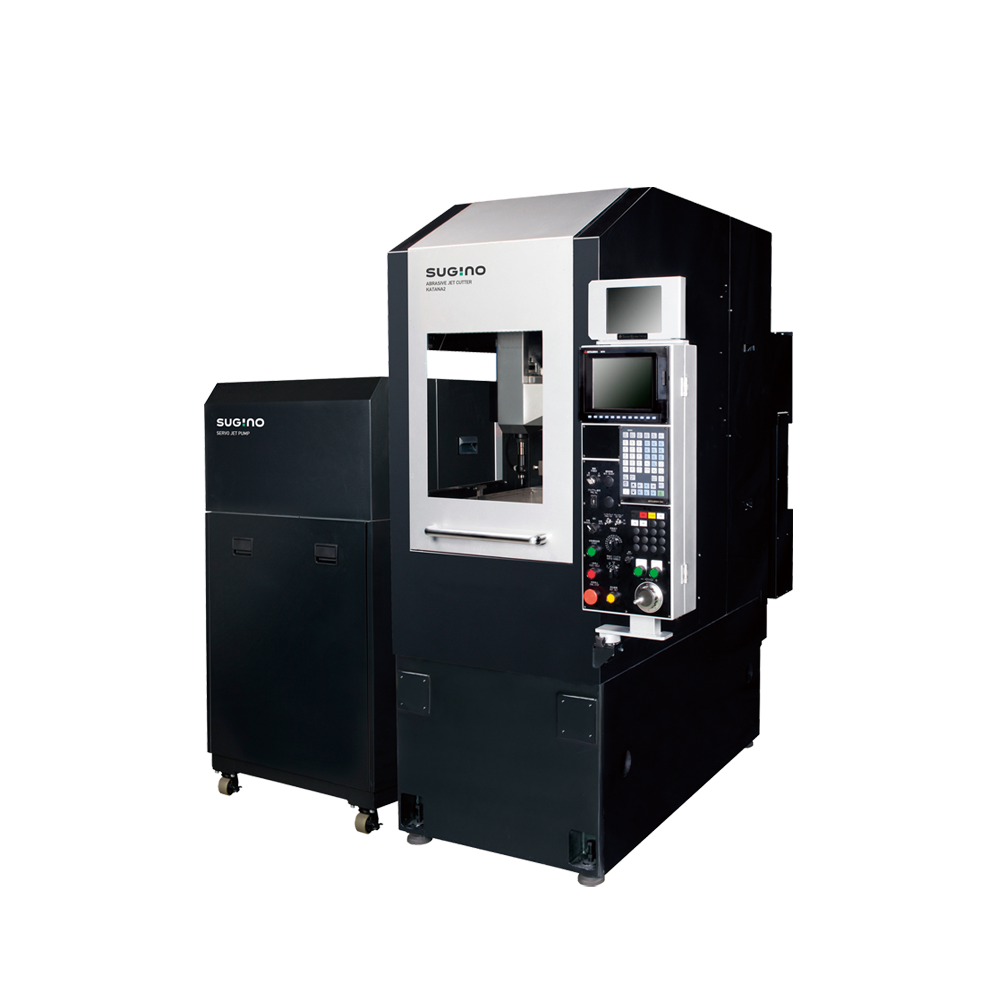

Water Jet Cutter KATANA2: Comapct Ultrahigh-Pressure Water Cutting Equipment

ABRRASIVE JET CUTTER KATANA2

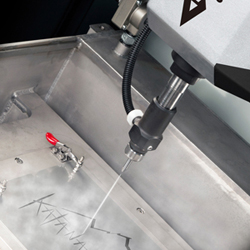

“Water Jet Cutter KATANA2” is a cutting device that cuts both hard and soft materials into any flat shapes by jetting a mixture of abrasive materials and water jet.

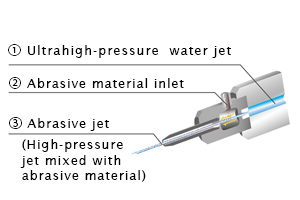

With a newly developed nozzle of no bigger than Φ0.5mm, it not only reduces the cutting allowance, thermal effect and noise but it also saves energy and the amount of abrasive materials, reduces initial costs and running costs, and has a low impact on environment.

Features

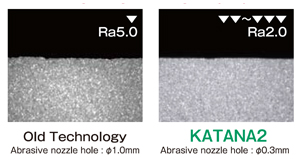

It processes more accurately!

By developing an ultrafine abrasive nozzle of Φ0.3 mm, it can process a cutting allowance as fine as 0.3mm.

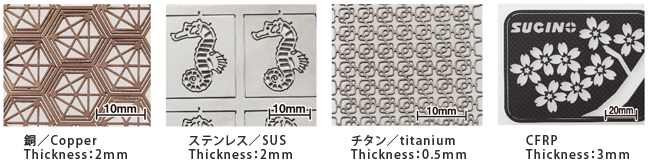

Accurately processes many types of materials

Accurately processes many types of materials

Besides all the merits of water jet processing, with a newly developed nozzle it can process high-grade products and improve the roughness of the surface.

Suitable materials:

Glass, stainless steel, copper, CFRP, laminated materials, resin, rubber, foam, paper, etc…

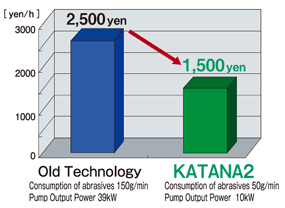

Energy saving, cost saving, space saving

Reduce 60% of abrasive materials.

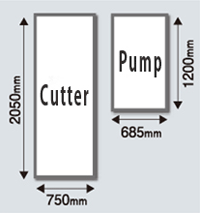

Installation space is only 3 m2.

Drastically reduces initial costs and running costs.

Specifications

| Diameter of abrasive nozzle | mm | Φ0.3 – 1.5 | |

| Movement range | X-axis | mm | 240 |

| Y-axis | 200 | ||

| Z-axis | 200 | ||

| Discharged pressure | MPa | Regular use 300, Max. 350 | |

| Discharged flow rate | L/min | Max. 0.65 | |

| Speed of fast-feeding | m/min | 30 | |

| Dimensions (body) | Width | mm | 750 |

| Depth | mm | 2,050 | |

| Height | mm | 2,100 | |

| Dimensions (pump) | Width | mm | 685 |

| Depth | mm | 1,200 | |

| Height | mm | 1,530 | |

| Power supply | ― | AC 200 V 18 kVA | |

Specifications above are just an example.

Application Examples

Machine parts: High-grade curve processing and micro processing for processing resistant materials

Cars, airplanes: Processing products of various kinds that are small in quantity, such as composite resin panels and difficult-to-cut materials

Job-shop: Processing and trial manufacturing new materials

Used instead of laser processing: Processing materials that laser processing does not work well on, such as glass and copper

Processing Examples