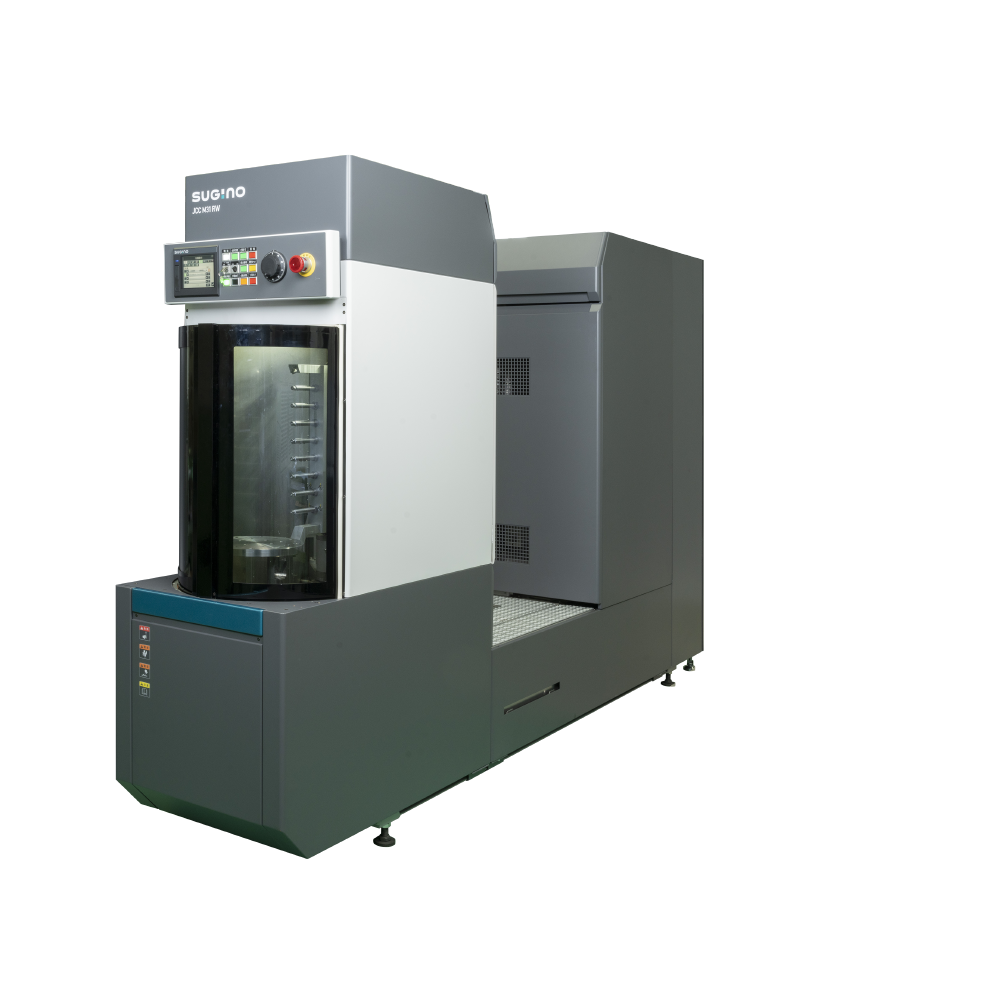

JCC-Module : Modular Washer

JCC-Module

Despite its incredibly compact width of only 600mm, this machine ensures reliable removal of chips from tapped and blind holes with its ‘Swing-Aiming Washing’ feature.

With large-flow washing using multiple nozzles, chips and oil on the workpiece surface are quickly and thoroughly cleaned.

By reducing manual chip removal and inspection processes, production costs are minimized!

- Product introduction video

- The secret to high-speed and high-precision cleaning: ‘Swing-Aiming Washing’(PAT.)

- Pursuing ease of installation and daily usage.

- Additionally, automation and labor-saving for washing and drying can be easily achieved by combining multiple units with transport systems, thanks to NC control.

- Main Specifications

Product introduction video

The secret to high-speed and high-precision cleaning: ‘Swing-Aiming Washing’(PAT.)

The ‘Swing-Aiming Washing ‘ system features three synchronized servo axes—one for the rotation axis of the workpiece and two for the vertical and horizontal movements of the nozzles—ensuring continuous, precise targeting and spraying at the holes.

By precisely targeting tapped and blind holes, high-precision washing is achieved.

Additionally, high-speed positioning with multiple axes and large-flow spraying from multiple nozzles enable rapid washing of the entire workpiece!

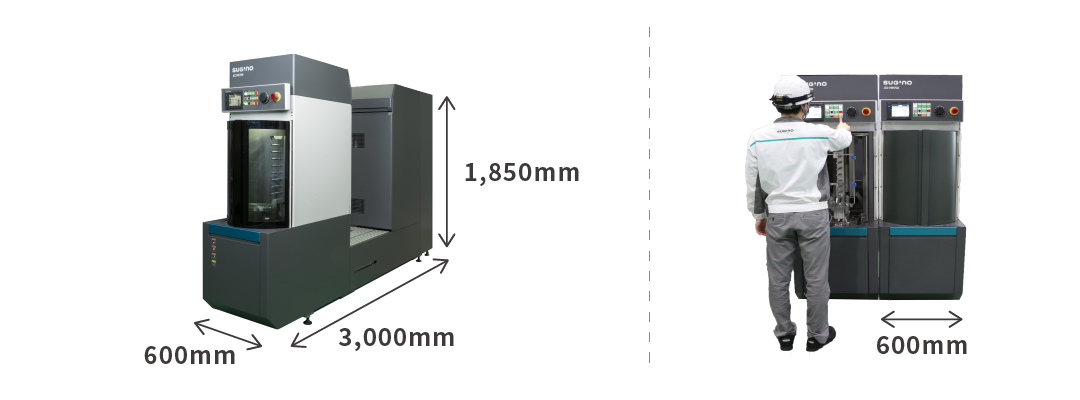

Pursuing ease of installation and daily usage.

Each module is compact with a width of 600mm, allowing for use even in limited space within the factory.

Necessary functions and processes can be added to existing lines as well.

Additionally, automation and labor-saving for washing and drying can be easily achieved by combining multiple units with transport systems, thanks to NC control.

Additionally, automation and labor-saving for washing and drying can be easily achieved by combining multiple units with transport systems, thanks to NC control.

JCC-Module received the 2021 Good Design Award!

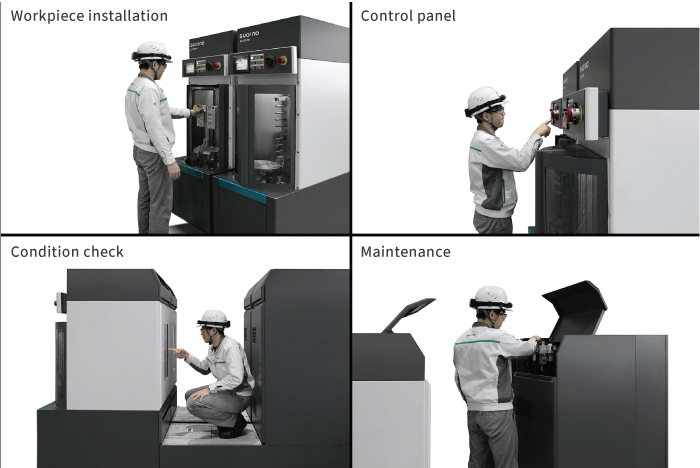

Focusing on intuitive design, we aimed to create a system that is easy to operate whether using a single unit or multiple units, regardless of the operator’s skill or experience.

Key Design Features

Thoroughly compact design for easy integration into any factory, with a modular structure that separates functions.

An intuitive layout height for easy handling by users, including the workflow, operation, and maintenance.

Functional color-coding for clear differentiation.

Main Specifications

| Product Name | 「JCC-Module」Modular Washer |

| Applications | ・Removal of cutting chips stuck in tapped holes and blind holes ・Removal of chips and oil adhering to the entire surface of the workpiece. Degreasing Application examples: parts for EV/HV vehicles, transmission gears, shafts, car air conditioning units, etc. |

| Washing Specifications | 1.0MPa×100L/min or 7.0MPa×15L/min |

| Controller | CNC |

| Positioning | Oscillation (Servo) + Up/Down (Servo) |

| Machine Dimensions | W 600mm × D 3,000mm × H 1,850mm |

| Applicable workpiece size | W 250mm × D 100mm × H 450mm *Workpiece size is indicative; larger workpieces may also be accommodated. Additionally, larger workpieces can be cleaned with the JCC-MULTI as well. |

| Machine Weight | 1,600kg |