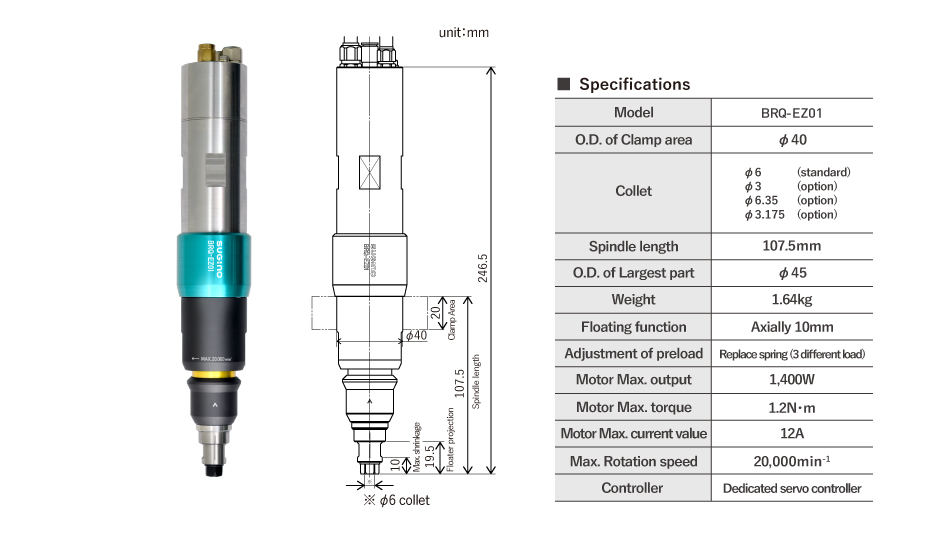

BARRIQUAN BRQ-EZ01: Spindle Motor for Automated Deburring with Robots

BARRIQUAN BRQ-EZ01

Typical deburring problems arise from automation

Features of BARRIQUAN BRQ-EZ01

1

Float mechanism flexes 10mm

The self-compensating float mechanism maintains even, constant pressure for uniform deburring without overcutting.

2

Highly Customizable

The floating holder is easily exchanged based on your needs, specific quality requirements, and part features.

4

Servo control resists load fluctuations

Maximum speed 20,000min-1. Servo controller provides stable control of motor even with load fluctuation.

5

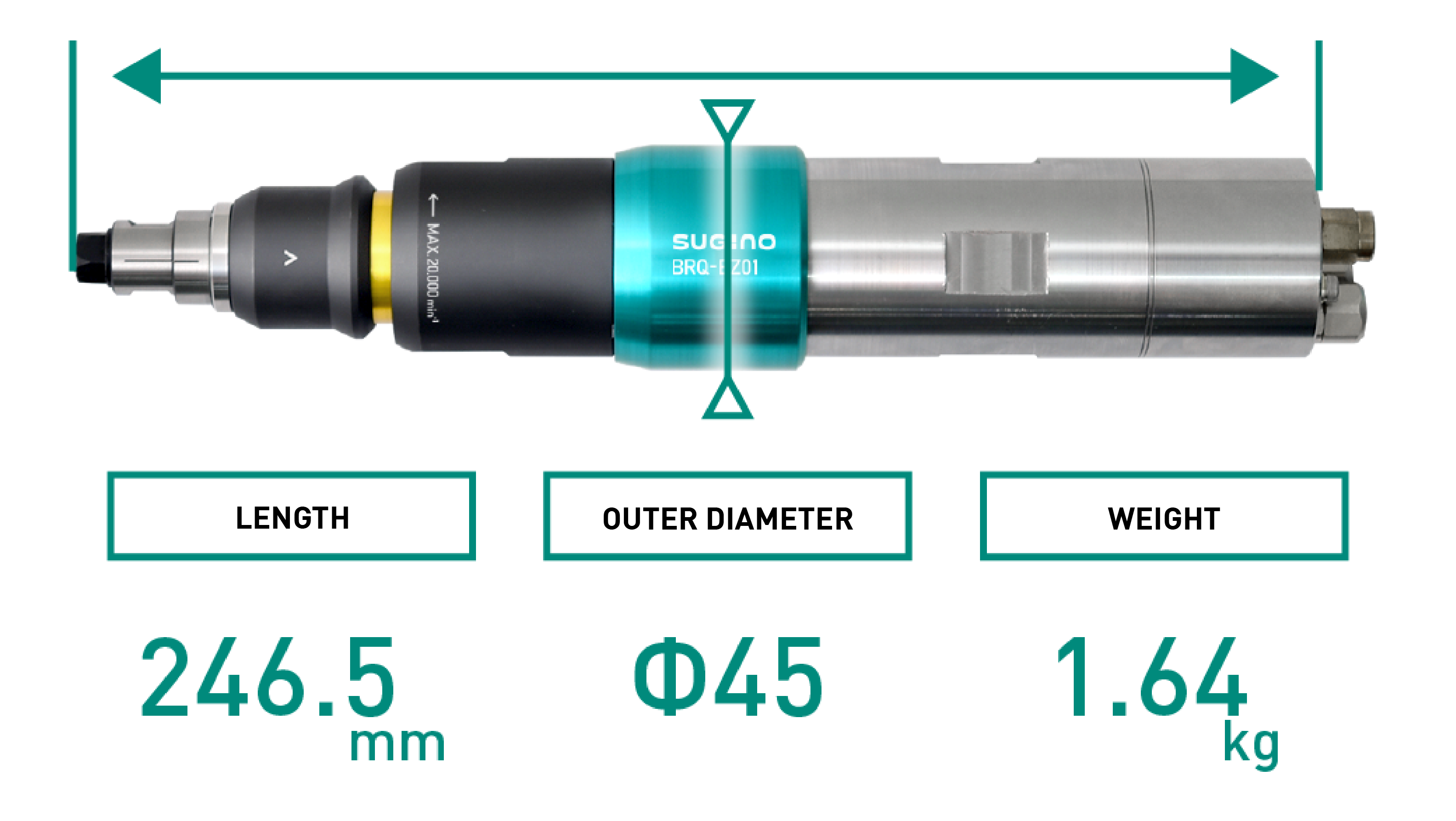

Slim design for less interference

Weight: 1.64kg, O.D.φ40×246.5L

Compact design.

1 10mm telescopic floating mechanism

Float deburring automatically adjusts the tool to the shape of the workpiece at a constant pressure, preventing residual burrs and over-shaving.

Finish with a uniform processing surface

The 10mm telescopic floating mechanism follows variations in the shape of the workpiece and compensates for ambiguity in the robot’s trajectory – for stable, uniform deburring.

Small robot friendly

The floating mechanism reduces the load on the robot and cutting tools, so it can be used with small robots (7 kg or more).

Stabilization of Tool Life

The floating mechanism reduces tool wear, even with intermittent and heavy load fluctuations.

2 Highly customizable

LG floater (standard type)

This standard type floats with thrust due to a straight-shaped sliding guide groove.

Because it is easy to change the size of the chamfer depending on the processing conditions, this standard model has a wide range of adaptations and can be used for most general purposes.

SG floater (highly responsive type)

A highly responsive type that floats, not only in thrust, but also in cutting torque due to the spiral-shaped sliding guide groove.

With improved tracking, and more sensitive floating than the standard type, the SG is recommended when targeted chamfer quality is required. Ideal applications include uniform deburring of complex shapes and thread chamfering of materials with good processability such as aluminum and copper.

SG floater for back (high reaction type) for back burrs

This high-reaction type for back deburring has an extended reach.

It is possible to deburr parts that are difficult to access with normal tools, such as missing burrs of drills and chamfering the back of large workpieces.

3 Quick disconnect of tool

BARRIQUAN BRQ-EZ01 has a one-touch mechanism for the part that holds the tool (floater).

Various cutting tools can be easily interchanged, reducing the time required to determine conditions for blade selection, speed of rotation, and feed rate.

External setup is possible, reducing the time required for tool changes.

Maintenance is also easy, and with proper maintenance, the product can be used for a long time.

4 Servo control resists load fluctuations

A servo controller is used.

Can be set to any rotation speed up to 20,000min-1.

5 Slim design for less interference

BARRIQUAN BRQ-EZ01 is slim and compact design prevents interference with workpieces and jigs, and allows a high degree of freedom in deburring motion, allowing approaches from various directions.

BRQ-EZ01 Specifications