Instruction Manual BARRIQUAN [ C-FSB01 ]

Instruction Manual (Web Manual) of BARRIQUAN BRQ-TX01 for back burr removal, a tool holder for deburring with floating mechanism.

1. Precautions

2. Tool Selection

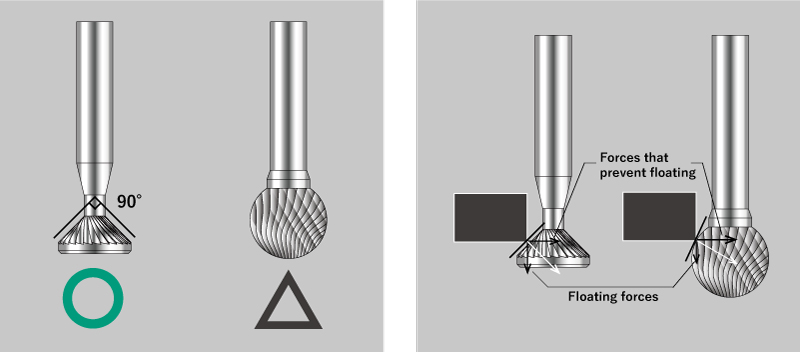

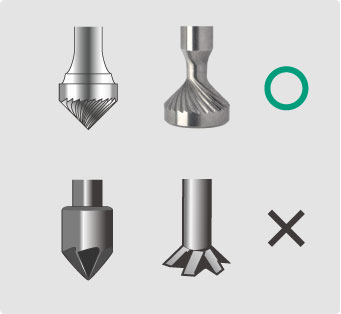

Cutter: 90° angle at the tip is recommended

A conical carbide rotary bar with a tip angle 90° is recommended.

Use of spherical cutters will shorten the life of the tool due to forces that prevent it from floating.

Cutter: The more blades, the better

A cutter with a large number of blades is preferable for float processing.

Fewer blades will deteriorate the finished surface.

3. How to Attach/Remove the Tool

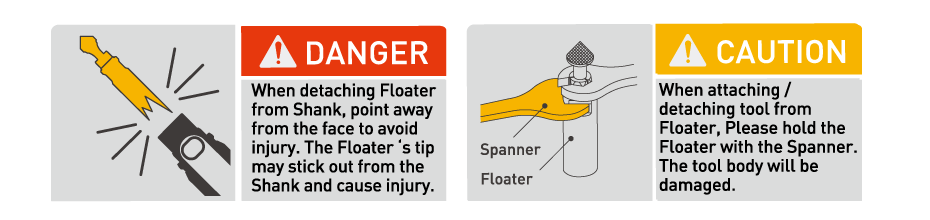

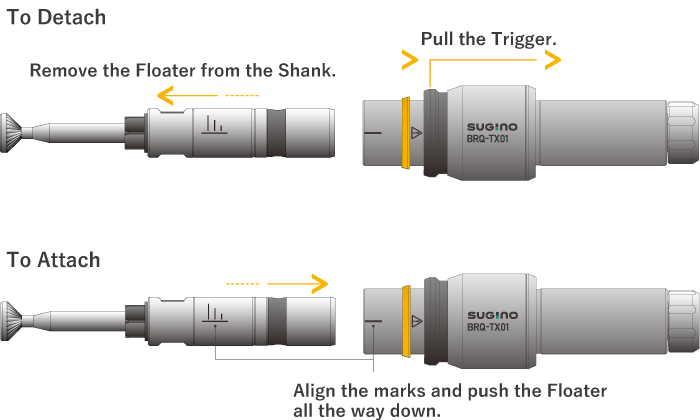

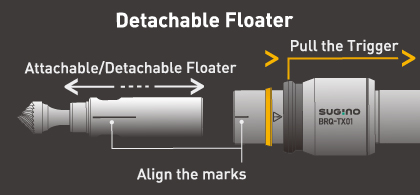

1. Remove the Floater from the Shank.

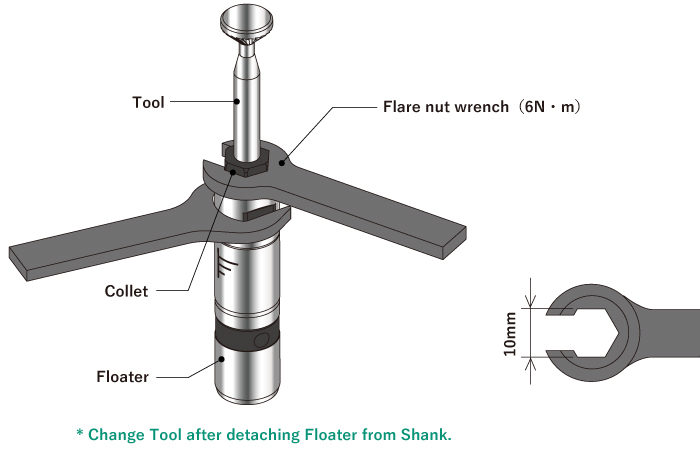

2. Attach the tip tool to the Floater. (Remove the tip tool from the Floater.)

CAUTION

- Use a flare nut wrench (3-point support) to screw in the collet.

- Using a spanner (2-point support) to screw in the collet causes deflection of the tool and affects the finish of the working surface.

- Attach the tip tool to a φ6 collet (spanner size 10, 13).

- The tightening torque of the collet is 6 N・m.

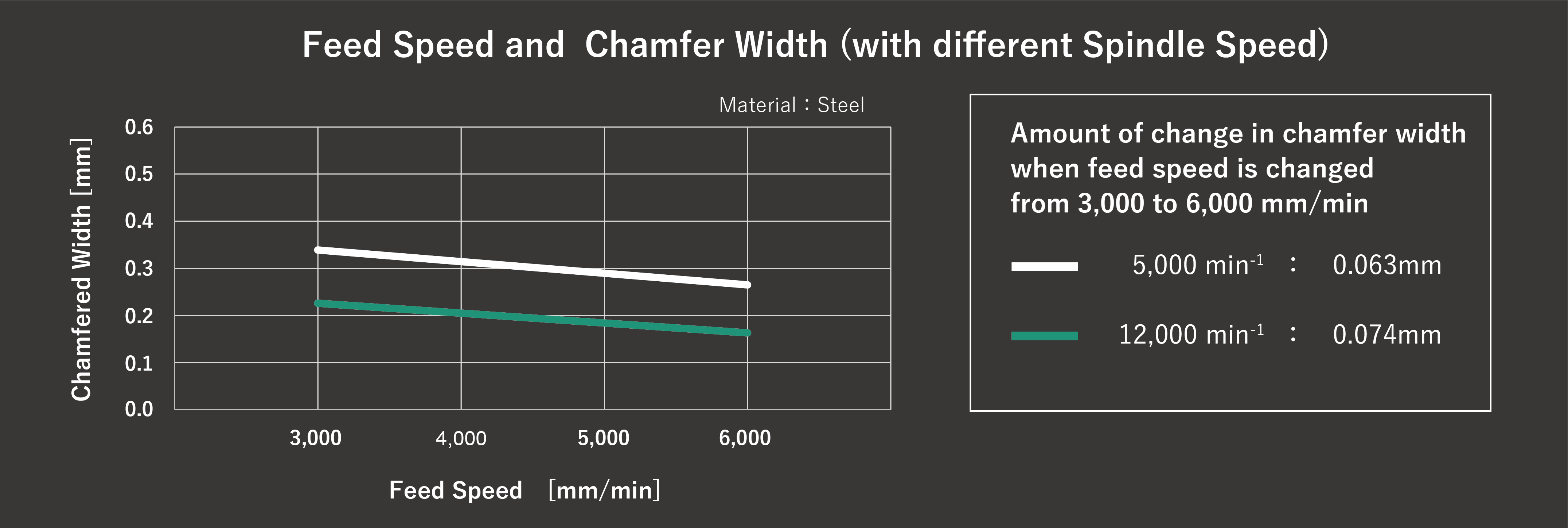

4. Rotation Speed and Feed Speed

Use a rotational speed in the range of 2,000 to 12,000 min-1.

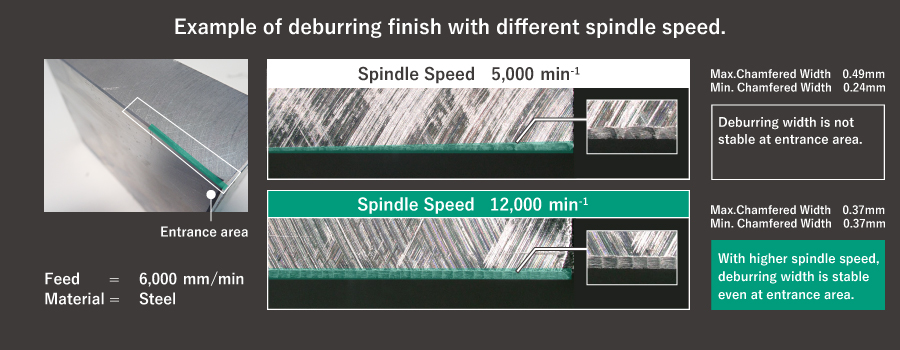

Although the entrance area is one of the most difficult areas with float deburring, you can obtain stable deburring surface with high spindle speed.

High-speed, high-feed processing shortens cutting time

The guideline ratio of spindle speed (min-1) and feed speed (mm/min) is approx. 1 : 0.3 – 0.6.

Higher spindle speed enables higher feed speed.

Smaller deburring cuts can be obtained at higher spindle speeds.

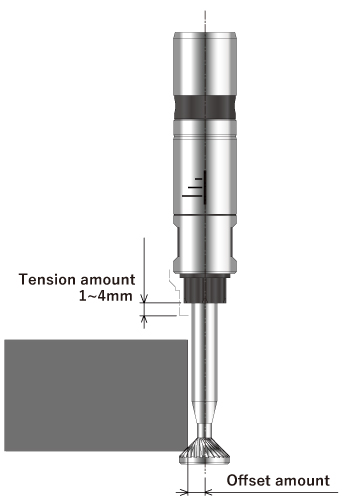

5. Offset Amount and Compression Amount

Set the offset amount to 4.5 mm for the cutter C-BF01 (made by Sugino Machine) for back burrs as a guide.

Set the compression amount from 1 to 4 mm as a guide.

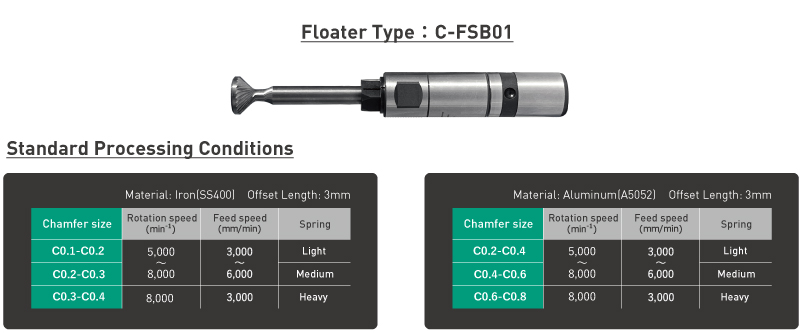

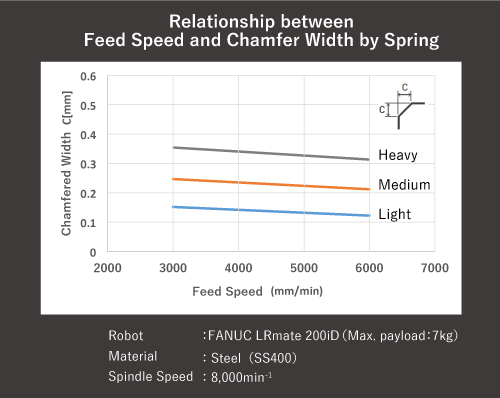

6. Approximate processing conditions

For ferrous materials, the minimum chamfer width is 0.1 mm and the maximum is approx. 0.4 mm.

For nonferrous materials (such as aluminum A5052), the minimum chamfer width is 0.2 mm and the maximum is approx. 0.8 mm.

Soft materials tend to have large chamfer widths.

If runout occurs when installing the tool, the chamfer width will increase.

Set the tip runout accuracy of 0.01 mm/rev or less when processing smaller chamfer widths.

7. Setting the Pressure

First, use the Spring (medium) assembled in the main body for processing.

If you want to increase the chamfer, replace the Spring (heavy).

If you want to make the chamfer smaller, replace the Spring (light).

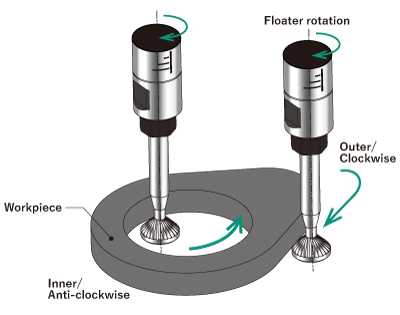

8. Setting the Tool Path

Create a Tool path so that a down-cut is performed.

9. Maintenance

1.Replacement of Tip Tool

Replace the tip tool with a new one when the blade is chipped or cutting power is significantly reduced.

2.Maintenance/Replacement of Floater

Replacement of Floater

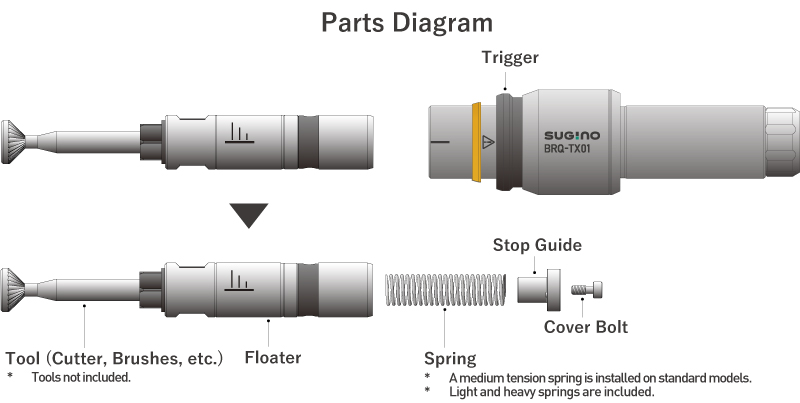

You can pull the Trigger and change the Floater in 3 seconds.

No need to waste your time for tool changes.

Maintenance

No tool is required for daily maintenance.

Daily maintenance will extend lifetime of BARRIQUAN.

Replace the Floater when scratches or dents occur on the outer surface of the Floater.

CAUTION

- Be careful to avoid deformation of the two-sided portion of the Floater when attaching/removing the tool. If the Floater is deformed, the extending/contracting mechanism may not operate properly.

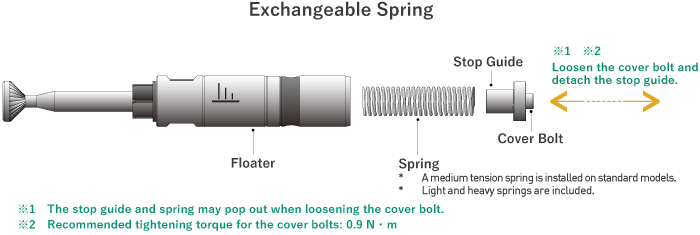

3.Replacement of Spring

Replace the Spring after 100,000 cycles.

Coil springs lose tension after prolonged use.