SELFEEDER DUO SD4 : Servo Feed Drilling and Tapping Unit

SELFEEDER DUO SD4

SD4 type is a model with increased spindle torque and thrust copared to the SELFEEDER DUO (SD3), which is capable of both drilling and tappig in one unit.

Increased productivity by high-speed, high-feed machining, and speed reducer plus simultaneous machining multiple holes.

Max. drilling size … φ18(Steel)/φ12(Aluminum)

Max. tapping size … M24(Steel)/ M22(Aluminum)

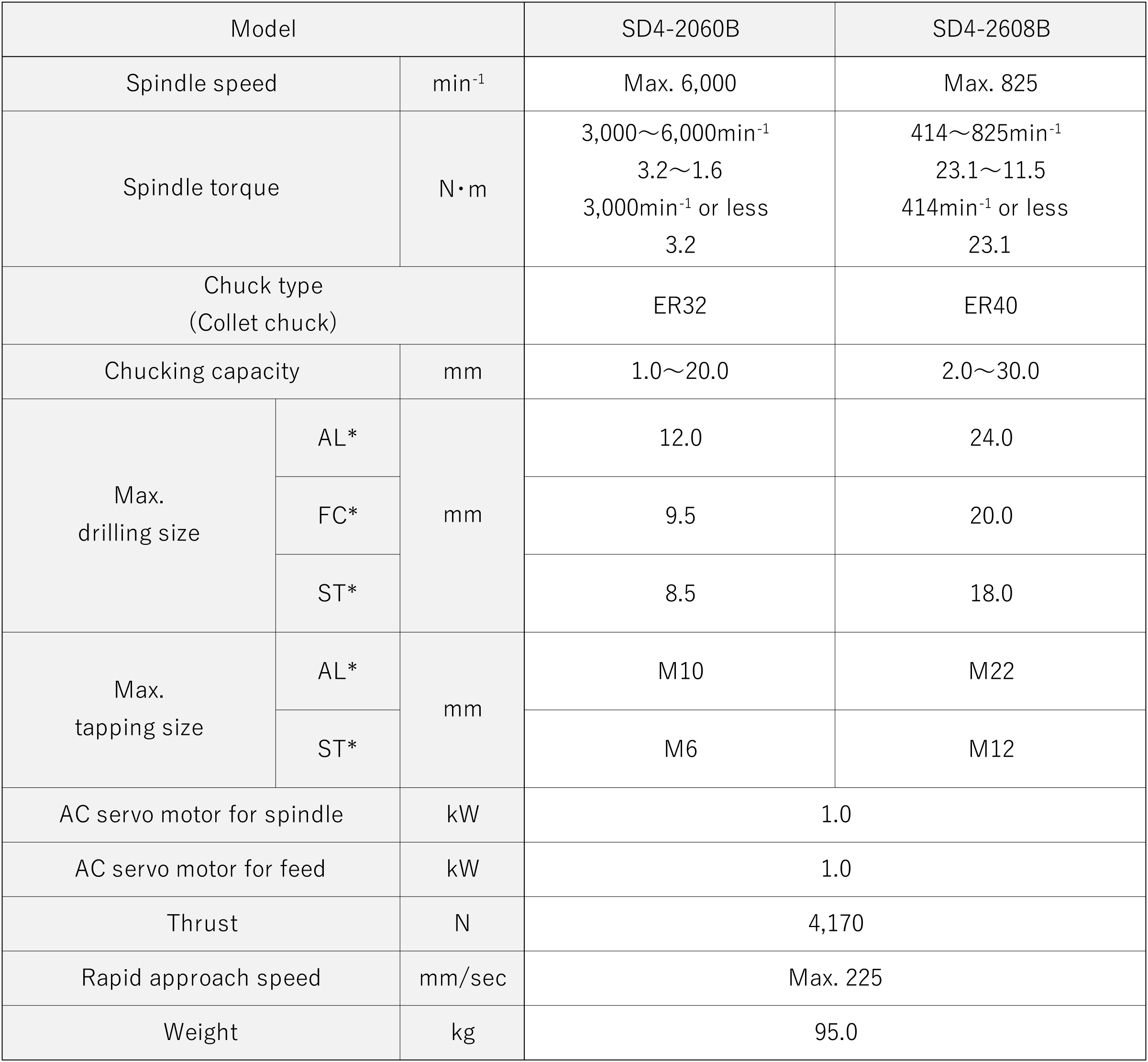

Specification Chart / Drilling and tapping dual-purpose type

Notes:

Select a model based on workpiece specifications, machinability, tool specifications and cutting speed.

The maximum drilling capacity shown above is the value at a drilling depth of twice the drill diameter.

Tapping capacities are conditional on the depth of tapping being limited to 1.5 times of the tap diameter.If the maximum drilling capacity exceeds the chucking capacity, special tools (with steps) shall be prepared by the customer.

If your drilling and tapping needs exceed the figures in the capacity chart, please contact the nearest sales office.

ER collet is adopted for spindle nose. Use collet ER-GB when chucking a tap.

Misalignment between a pre-hole and a tap can cause early tap damage, select a tap holder.

A servo motor for feed is with a holding brake, “B” is added to the end of SELFEEDER DUO model number.

AL : Aluminum(ADC12) , FC : Cast iron(FC200) , ST : Steel(S45C)

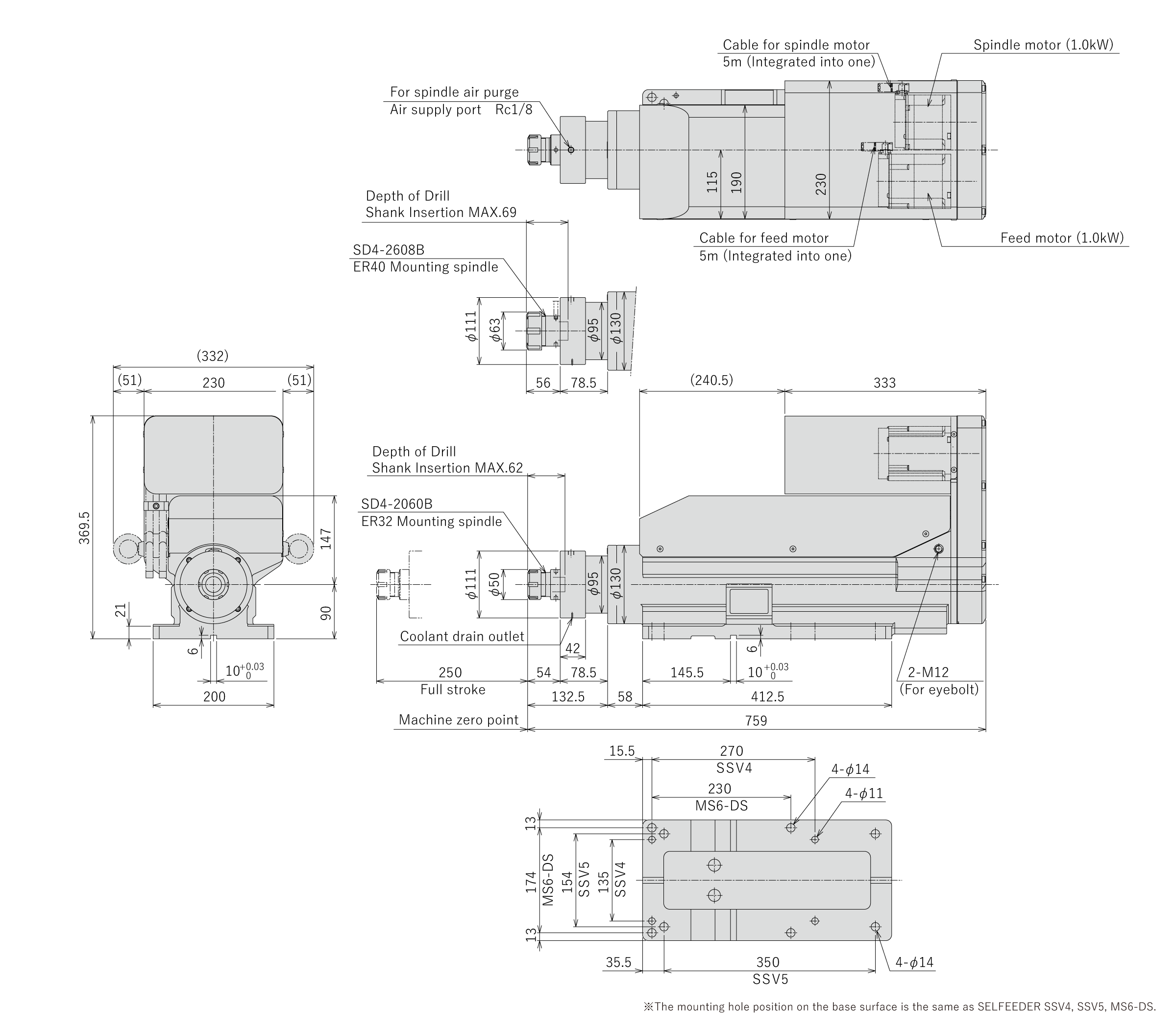

Dimensions

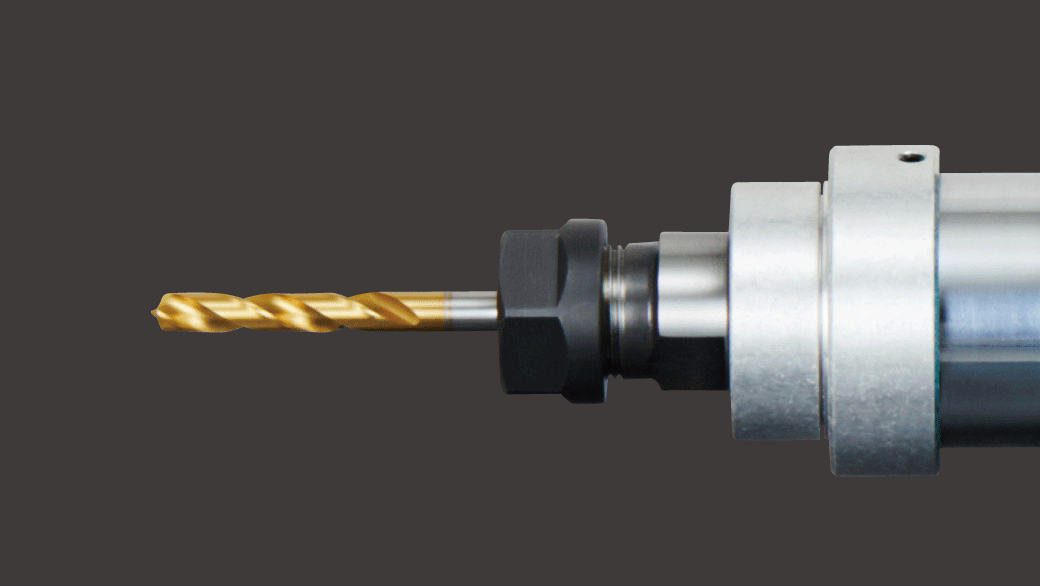

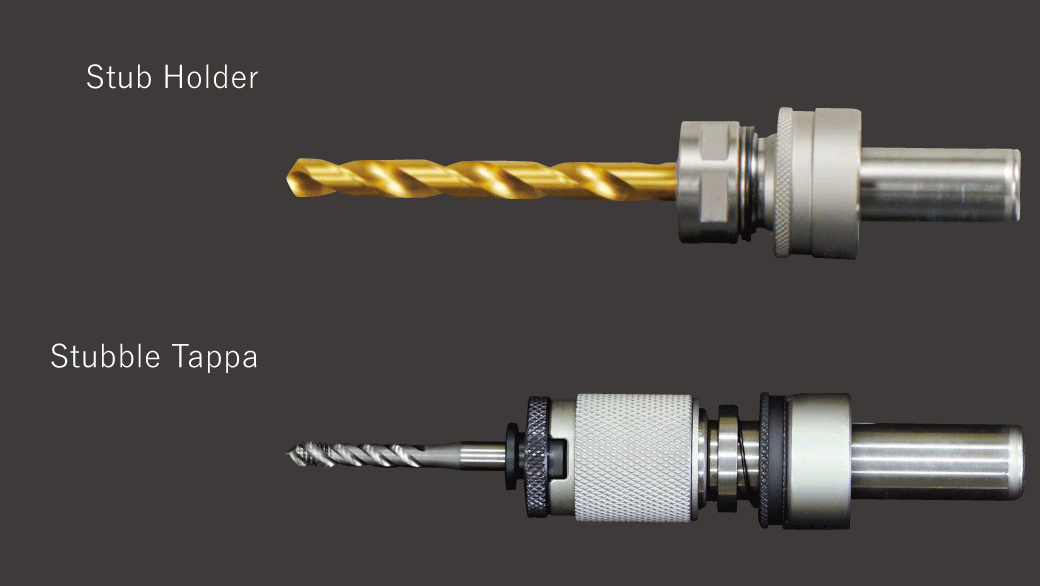

Selectable Spindle

Collet Chuck Spindle Nose Specification

Adjustable Spindle Nose Specification

Tap Holder

*Detailed drawings are listed in the catalog. CAD data can also be downloaded.

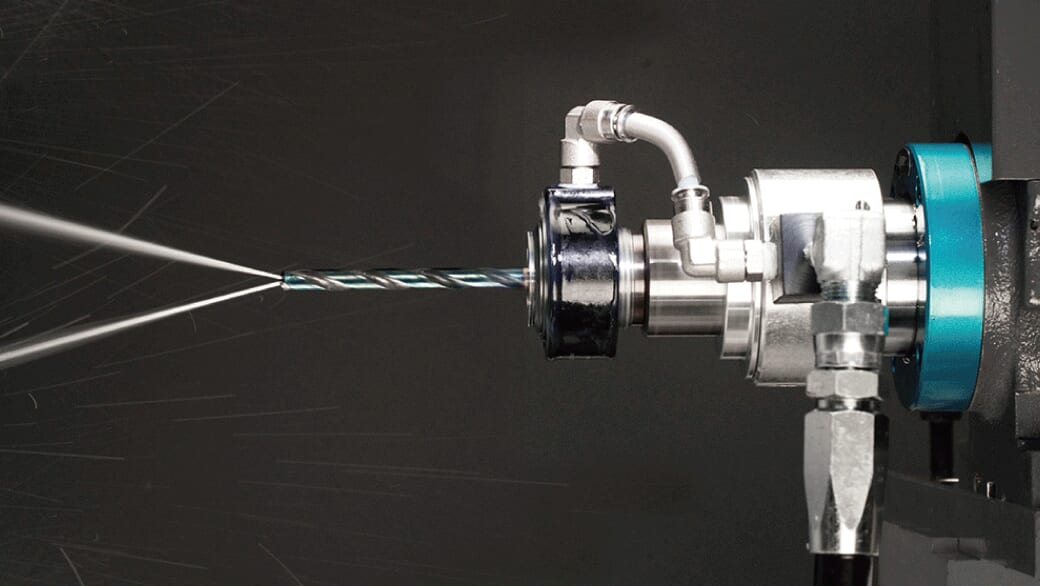

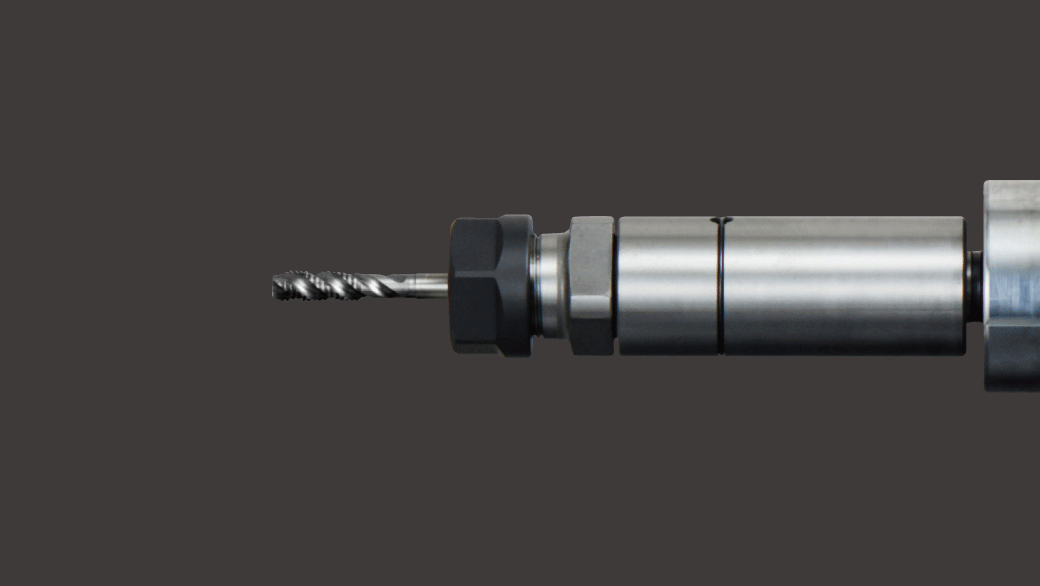

Coolant Through

Drills adn taps with oil holes can be used, and highly efficient deep hole drilling is possible.