SYNCHRO TAPPER SSTB : Mechanical Feed Tapping Units

SYNCHROTAPPER SSTB

Equipped with fast approach speed and fast return mechanism. A lightweight and compact mechanical feed type tapping unit.

“Synchro Tapper SSTB” can reduce the cycle time using the fast approach and fast return mechanism.

Compact and lightweight, with a high degree of freedom in mounting orientation, the dedicated machine can be space-saving.

The STB type has been renewed by replacing induction motor with a PM motor.

Max. tapping size… M10(Steel)/M12(Aluminum)

Features of the PM motor

1.Energy Saving

Energy consumption can be reduced by approximately 20% compared to a three-phase induction motor with the same output.

2.Global Support

Not subject to overseas high-efficiency motor regulations, making it easy to apply to equipment to be exported overseas.

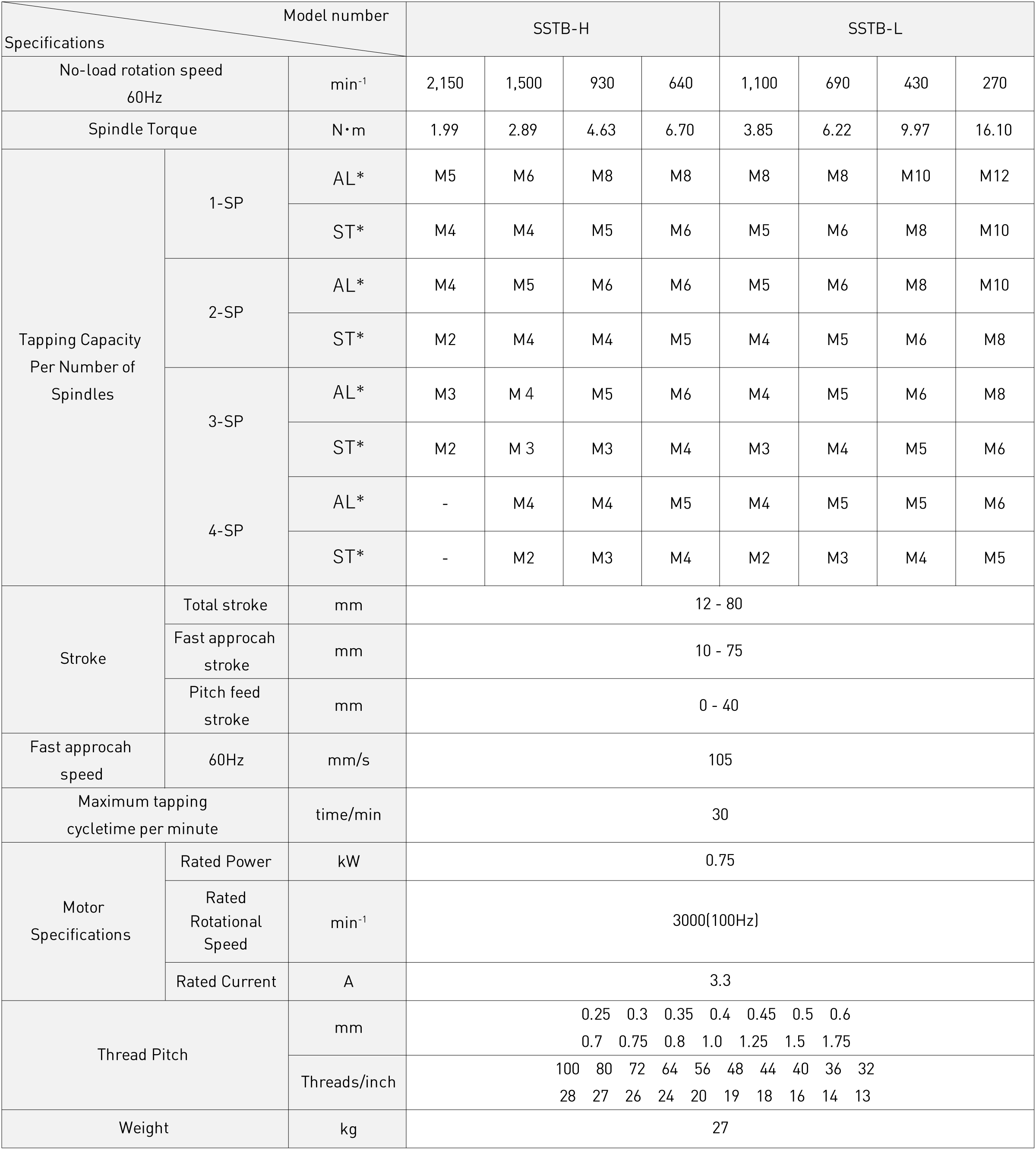

Specifications

Notes:

Regarding the two-step description of tapping capacity per number of axis, a spiral tap or a point tap is used for the upper column of the tapping capacity chart and hand tap No.2 is used for the lower column.

The allowance weight for the installable multi-spindle attachments is as follows: Waterproof and dust-proof measures for the Synchro Tapper main body are required for upward processing. For more information, please contact your nearest sales office.

(Sideways processing: 15 kg, Upward processing: 10 kg, Downward processing: 8 kg)AL : Aluminum(ADC12) , FC : Cast iron(FC200) , ST : Steel(S45C)

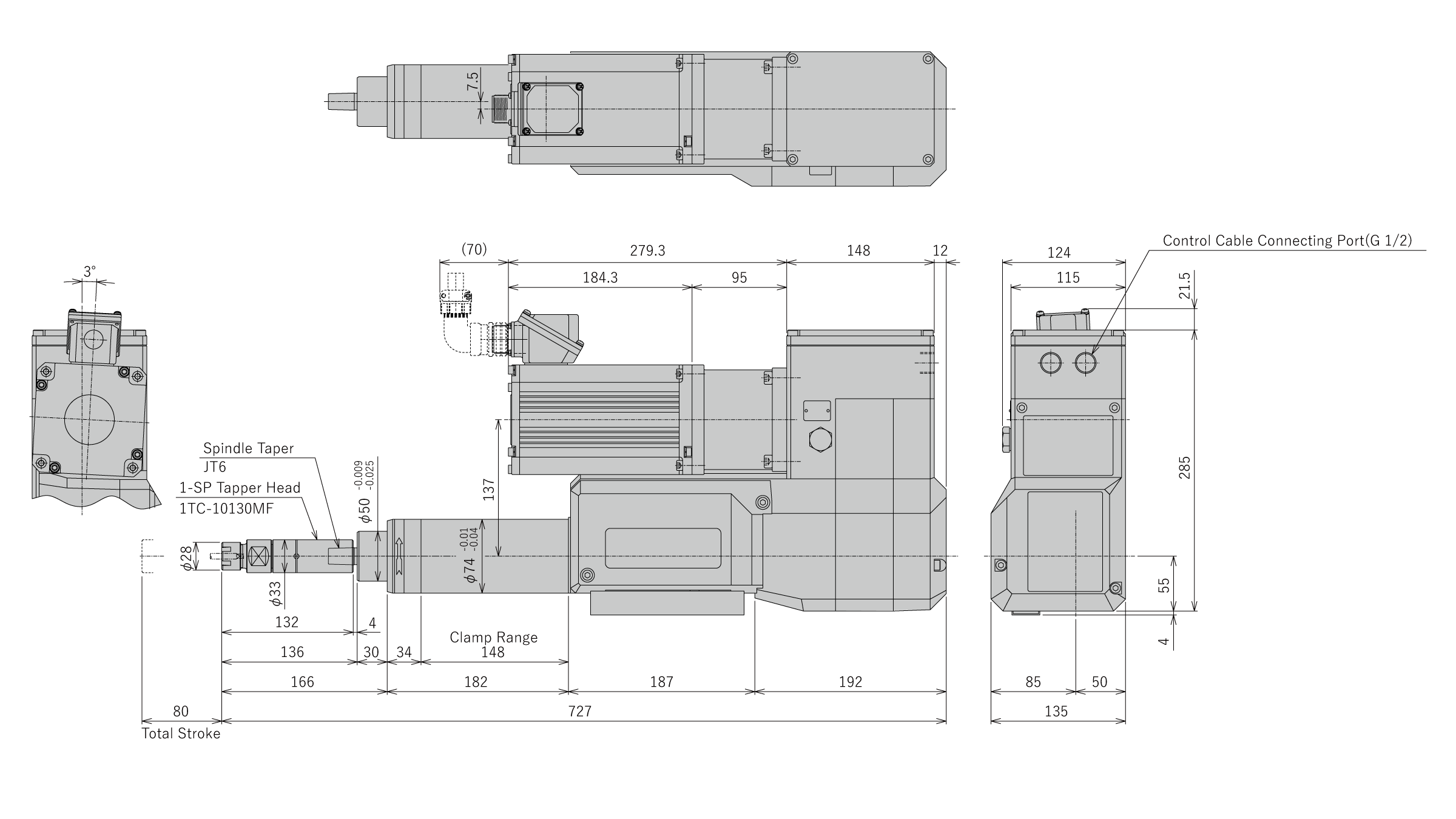

Dimensions

Peripherals (Optional)

Stand for unit installation

- Angle-adjustable stand “Flex Stand”

- Fixing attachment “Level Clamp”

Attachment

- Multi-Spindle Tapper Head

- 1-SP Tapper Head

Controller

- UC-30