Intensifier – Type Pumps / Water Jet Pump Units

SUGINO PUMP WATER JET PUMP

Intensifier-type pump units that can generate ultrahigh-pressure water up to 600 MPa.

Water Jet Pump: Hydraulic Intensifier Type / Ultrahigh-Pressure Pump

Hydraulic ultrahigh-pressure pump units that can generate ultrahigh-pressure water

up to 600 MPa. Using a hydraulic-driven intensifier (booster), this unit can generate

ultrahigh-pressure by intensifying the pressure of the secondary side 14 to 20 times higher

than the primary side hydraulic pressure.

Max.Discharge Pressure : 600MPa

Max.Discharge Rate : 13.5L/min

Max.Required power : 77kW

Features

- Continuous operation is possible.:Ultrahigh-pressure pump units with excellent durability capable of long continuous operation at a ultrahigh-pressure up to 600 MPa.

- Various Models Available:A wide variety of models are available from 19kW to 77kW. Proper model can be selected according to application.

- Long-lasting:Features a new intensifier that makes it possible to deliver a high flow rate while maintaining a lightweight, compact size. Maintenance is easy, and the system’s long life helps keep running costs down.

- Stand-alone Pump Operation Possible:ポA control panel enabling stand-alone pump operation is fitted as a standard equipment. The control panel is equipped with operation and display functions for immediate use once the system is delivered, with due consideration paid to safety in the design. Operational control using external signals is also possible.

- Excellent Operability:Offers excellent operability through the use of a touch panel. Besides a monitoring function which allows the user to monitor the state of the pump, the system also comes equipped with a troubleshooting function to allow a quick response to be provided when an alarm sounds.

Application Examples

Cardboard cutting

Urethane cutting

Trimming of automotive interior materials

Glass profiling

Precision cutting of artificial marble

Packing profiling

Instrument panel trimming

AQUA SERVO PUMP: Servo motor driven type / Ultrahigh-pressure pump units

Aqua Servo Pump are ultrahigh-pressure pump units that can generate ultrahigh-pressure water up to 600MPa.

Stable pressure waveforms from extremely low pressure to ultrahigh-pressure can be obtained by servo energy saving control.

Max.Discharge Pressure : 600MPa

Max.Discharge Rate : 4.4L/min

Max.Required power : 47kW

Energy-saving model

Features

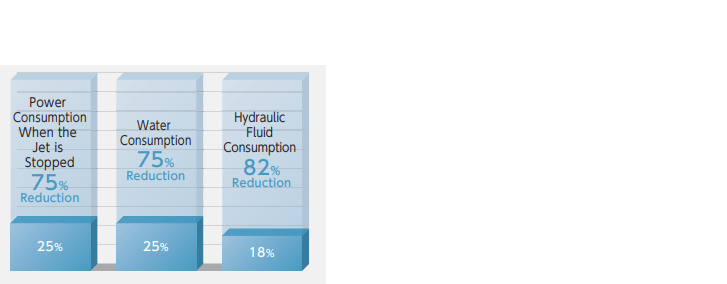

Energy Saving

The efficiency of the hydraulic circuit is improved by the dual directional control of the servo motor. The power consumption, water consumption, and hydraulic fluid consumption can be reduced. (compared to our company’s conventional models)

Reduction Control of Pressure Fluctuation is Possible

A constant pressure can be maintained through feedback control of servo motor rotation.

High Quality Piercing is Possible

Delamination or peeling of difficult-to-cut materials such as CFRP can be reduced by the stable control of low pressure.

Long Life of High-pressure Accessories

Impact pressure at the time when the intensifier switches or injection stops is suppressed to reduce impact loading to the high-pressure line.

Application Examples

■ Objects whose cutting surface roughness must be Highly Accurate

■ Piercing of the difficult-to-cut materials

■ Installation in facilities where the supply of hydraulic fluid is restricted

SERVO JET PUMP: Servo motor driven type / Ultrahigh-pressure pump units

Clean ultrahigh-pressure pump units with no hydraulic oil is used.

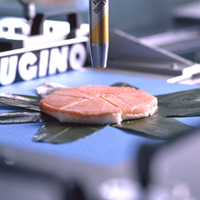

Best suited for cutting, emulsification,and cleaning of food, pharmaceuticals, semiconductors,etc.

Max.Discharge Pressure : 600MPa

Max.Discharge Rate : 4.4L/min

Max.Required power : 47kW

Clean/ Oil-free

Features

High efficiency and energy saving: Due to the direct drive system using a ball screw, the pump operates with high efficiency and does not require cooling water. When the injection stops, the load on the servo motor decreases, which also reduces power consumption.

Easy maintenance: No need to refill or replace hydraulic fluid, and the pump structure is extremely simple. The amount of maintenance work can be significantly reduced.

Low noise: Driven by a servo motor, it operates with low noise, providing a better working environment.

Application Examples

■ Emulsification of cosmetics and pharmaceuticals,

depolymerization, high pressure crystallization

■ High-pressure deburring of semiconductor parts

■ Cutting of printed circuit board and electronics parts

■ Cutting of Textile and disposable diaper

■ Cutting, sterilization, and denaturalization of food