Roller Burnishing Tool SUPEROLL SB [Inner Surface Blind-hole]

SUPEROLL SB

Multi Roller Type

Basic type SUPEROLL for inner surface burnishing (For blind-hole).

Equipped with tool diameter adjustment in increments of 0.0025mm.

![]()

Video

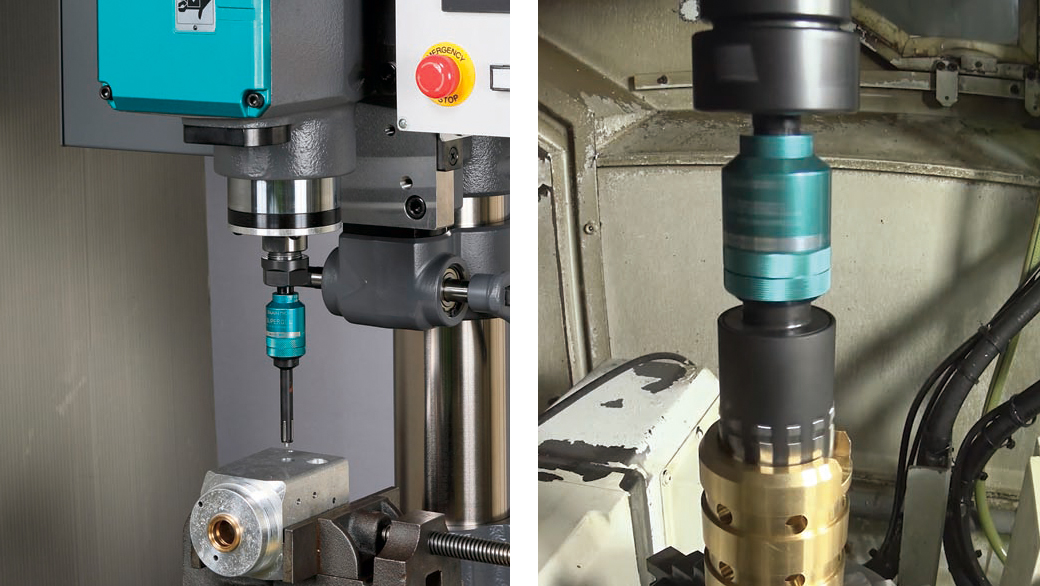

Burnishing scene

Product Information

Available workpiece shape: Blind-hole

Available driving units: Machining center, Engine lathe, Turret lathe, Drilling machine, Drilling unit

Hole size:

Standard: φ8.5 – φ200mm

Special: φ6.0mm or more

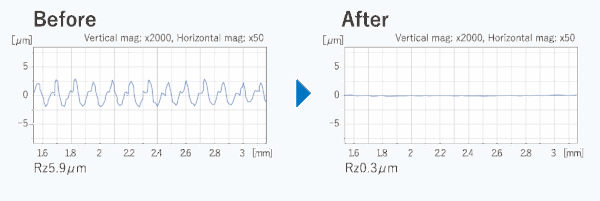

Burnishing data:

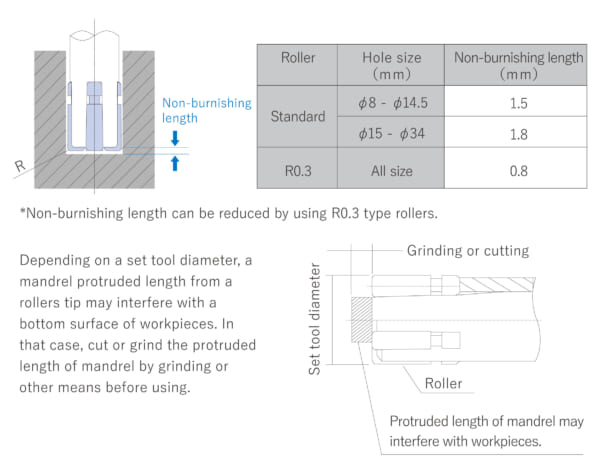

Non-burnishing length:

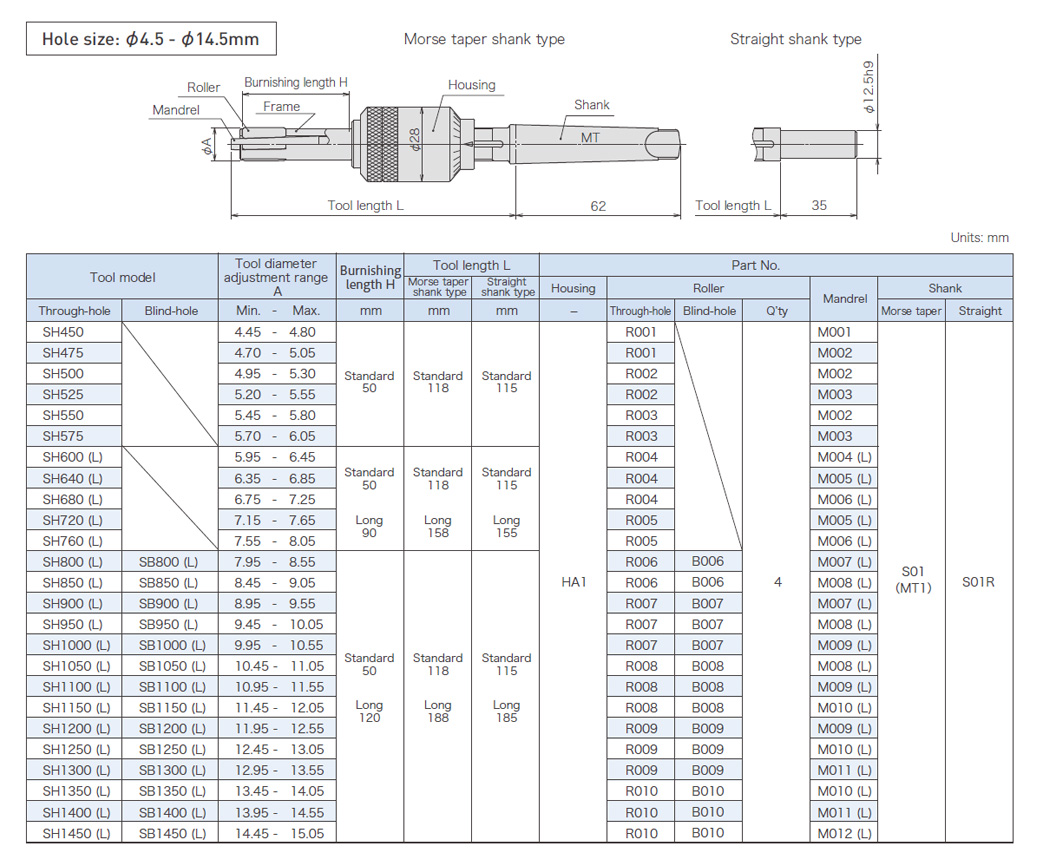

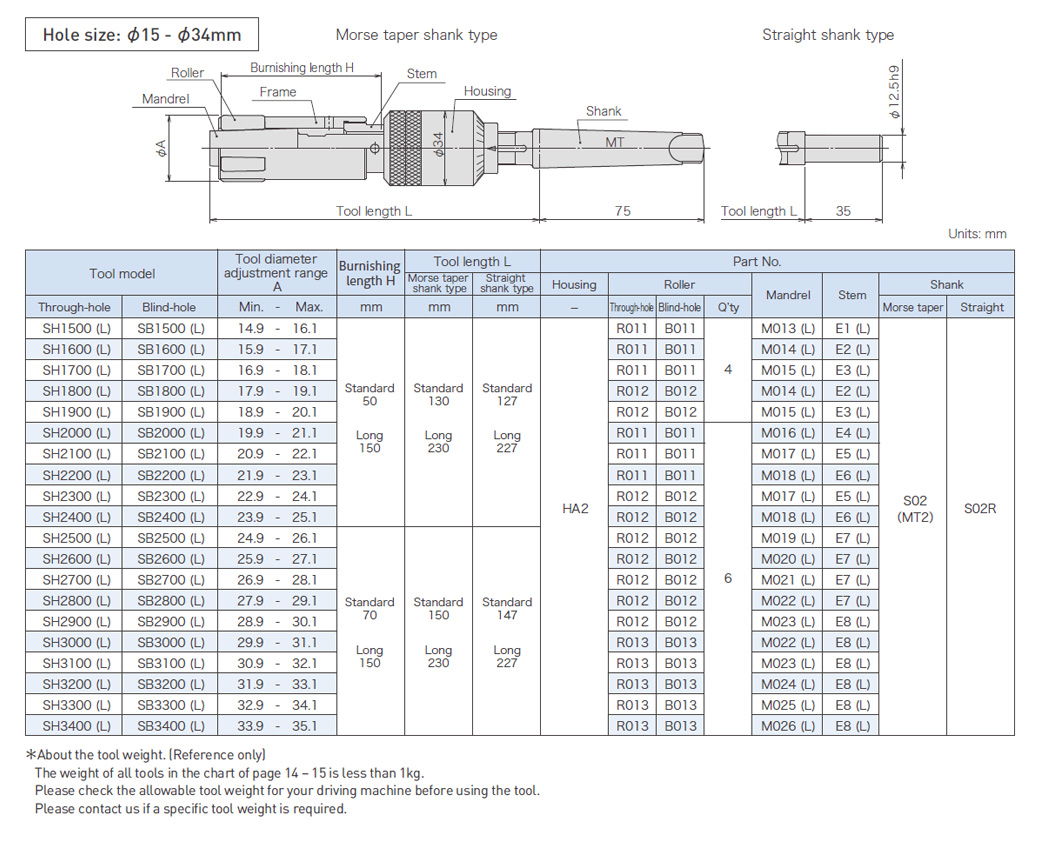

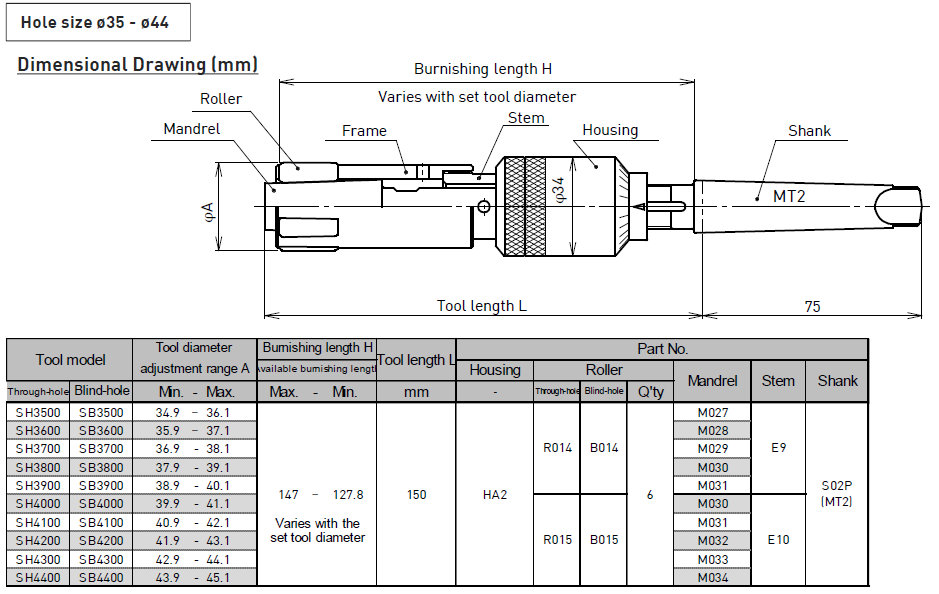

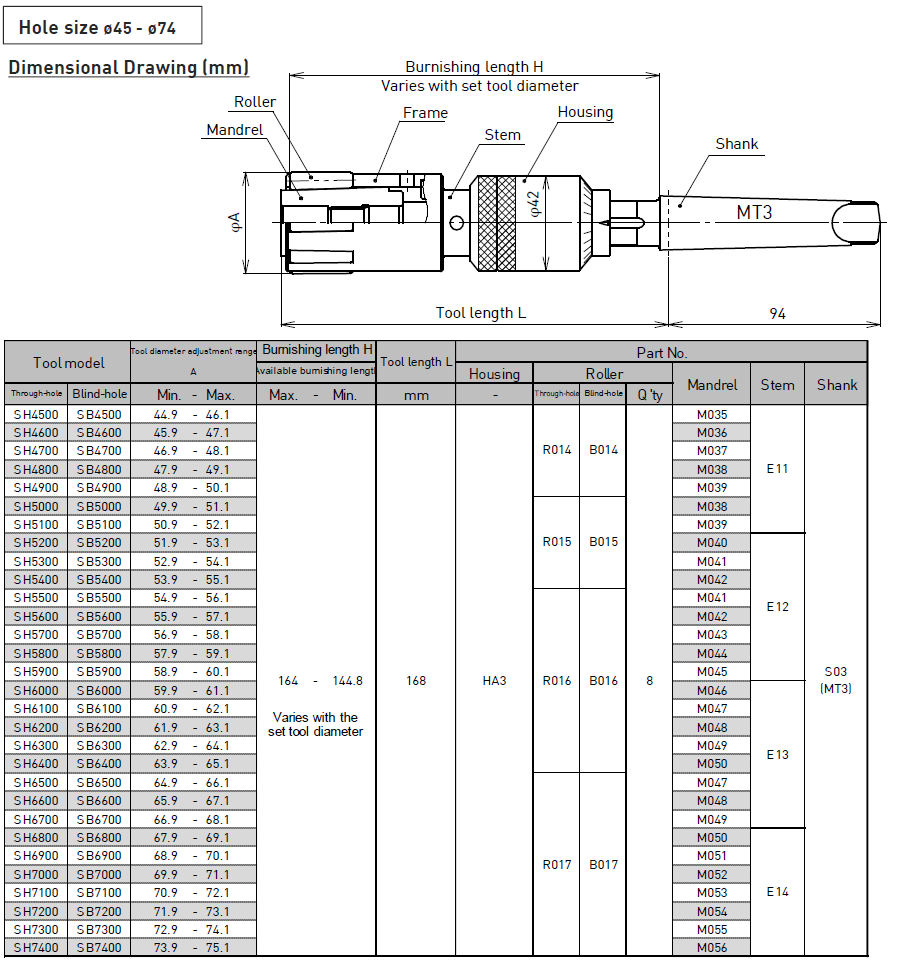

Selection chart (For hole size φ4.5 – φ74)

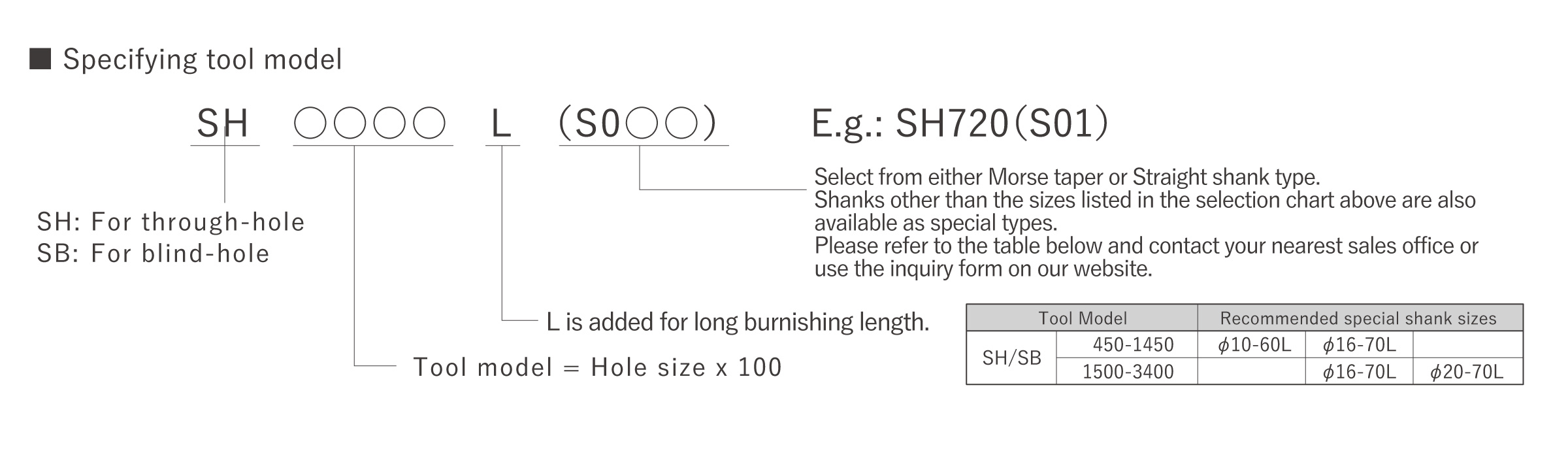

Specifying tool model

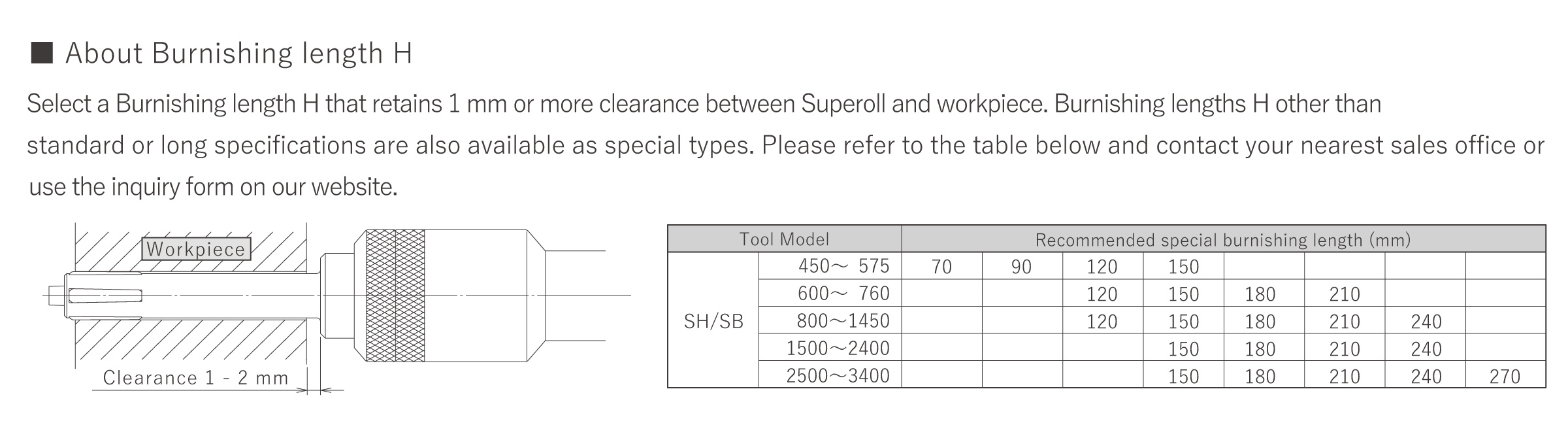

About Burnishing length H

Select a Burnishing length H that retains 1 mm or more clearance between SUPEROLL and workpiece. Burnishing lengths H other than standard or long specifications are also available as special types. Please refer to the table below and contact your nearest sales office by using the catalog inquiry sheet, or use the inquiry form on our website.

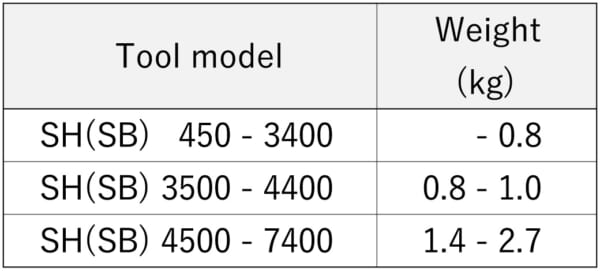

About the tool weight (Reference only)

Please check the allowable tool weight for your driving machine before using the tool.

Please contact us if a specific tool weight is required.

About tool selections

- Select Tool model within the Tool diameter adjustment range A to suit the hole size.

- For request a special dimensions not included in the SUPEROLL SH & SB selection chart, please contact your nearest sales office by using the catalog inquiry sheet, or use the inquiry form on our website.

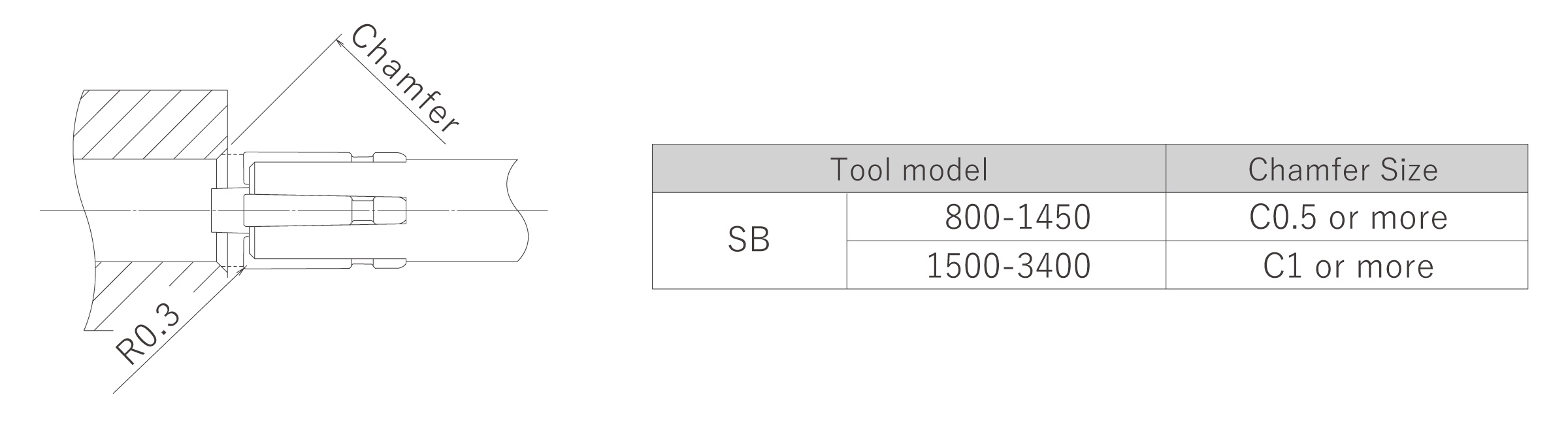

Precaution with R0.3 type rollers for SUPEROLL SB

When using R0.3 type rollers that reduce the non-burnishing length of blind-holes, the hole entrance must be chamfered to prevent interference between the roller tip and workpiece when inserting SUPEROLL SB.

Please refer to the chamfer size chart on the right for details.

Application Examples

- Brake & Master Cylinders

- Bearing insertion surfaces

- Hydraulic valves

- Shock absorbers

- HDD parts, etc.