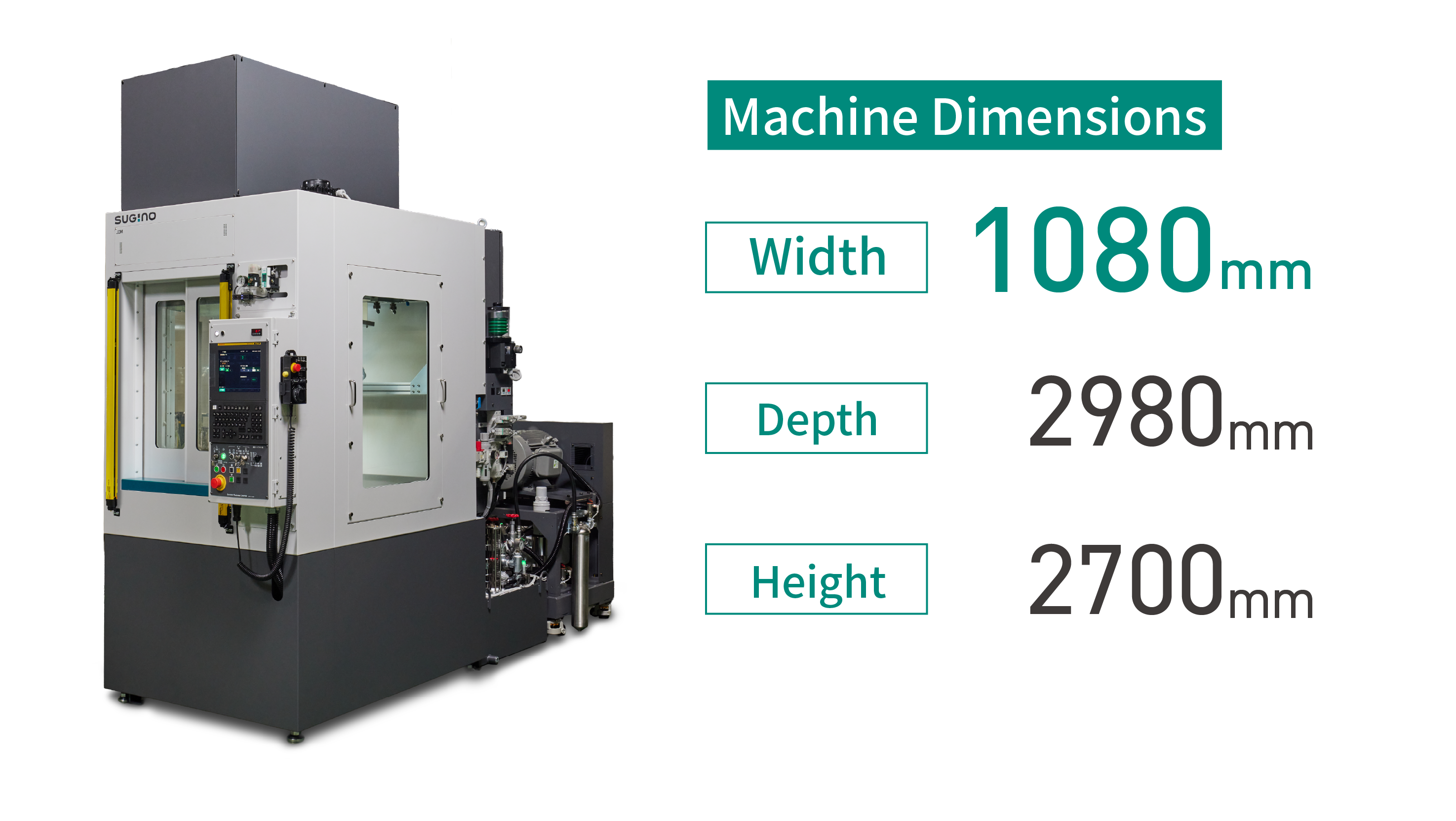

Water Jet Deburring Machine JDM

JDM

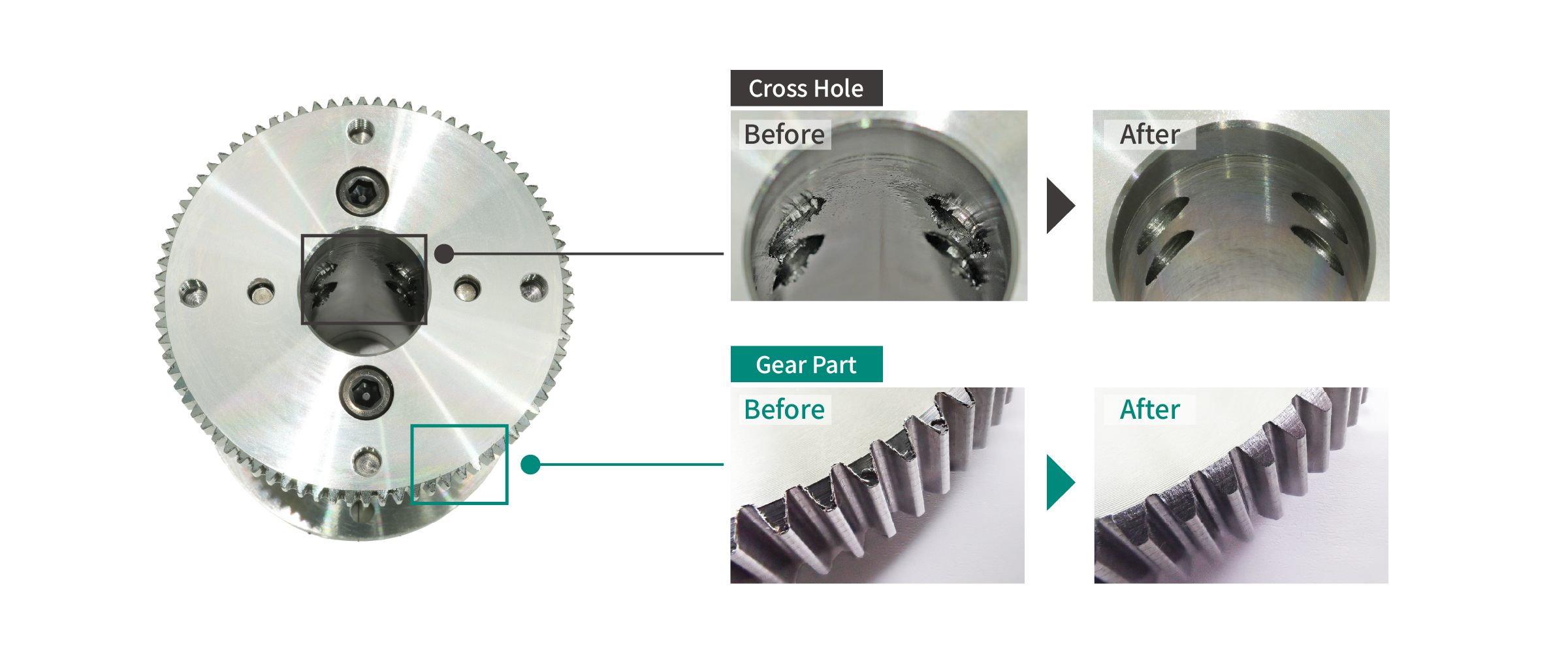

This product solves various burr-related problems using the water jet deburring technology.

It helps automate manual deburring and reduce labor requirements.

Features

1

Removes burrs with high-pressure water up to 70 MPa. Easily reaches areas that are difficult to access with tools.

2

New “Dual-Flow Nozzle” allows burr removal on five surfaces of the workpiece. Quick nozzle switching enables faster burr removal.

3

Equipped with an A-axis, it easily reaches the workpiece’s mounting surfaces.

4

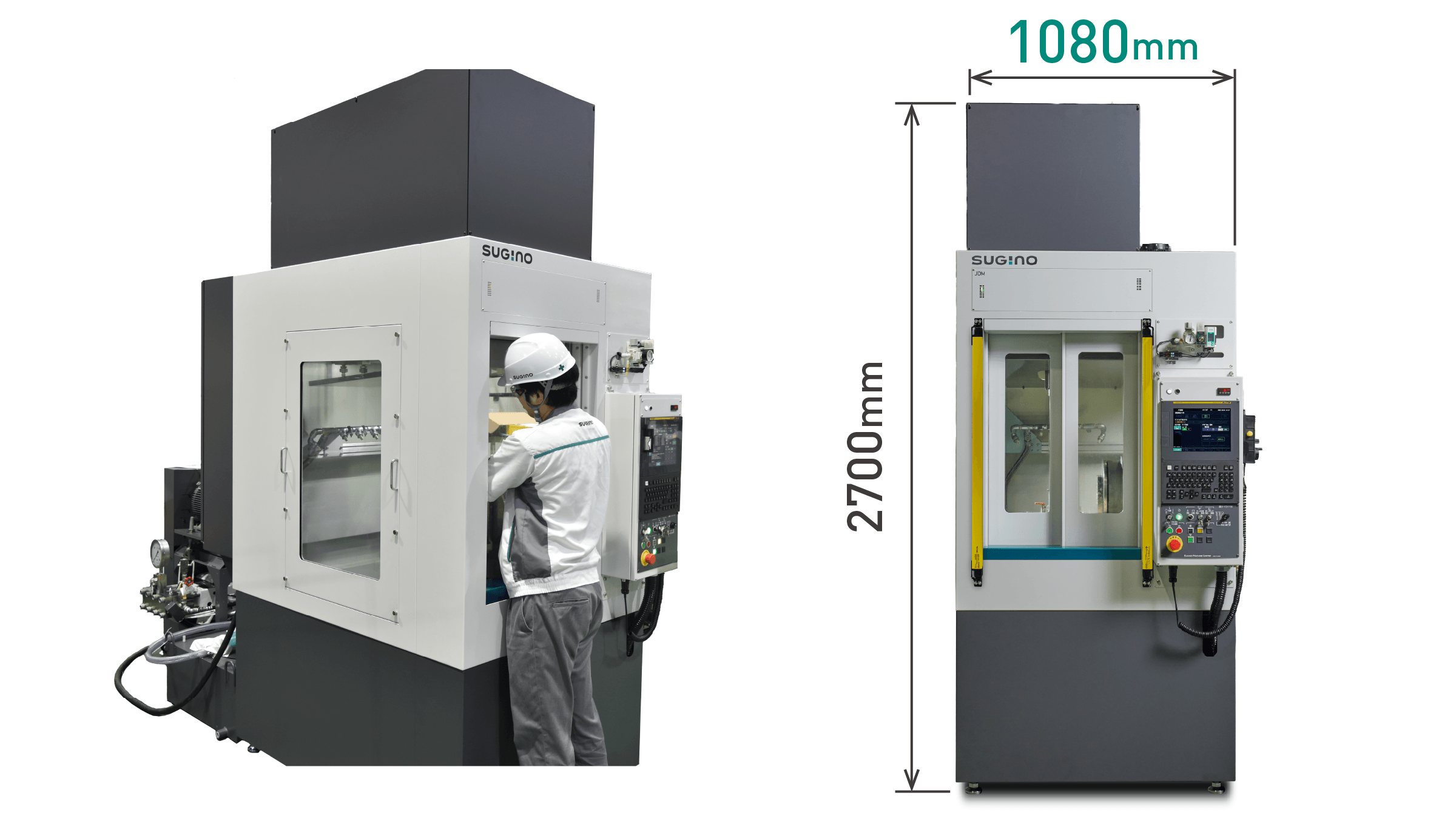

Compact deburring machine with a width of 1,080 mm. Automates deburring in a workspace as small as that of a single operator.

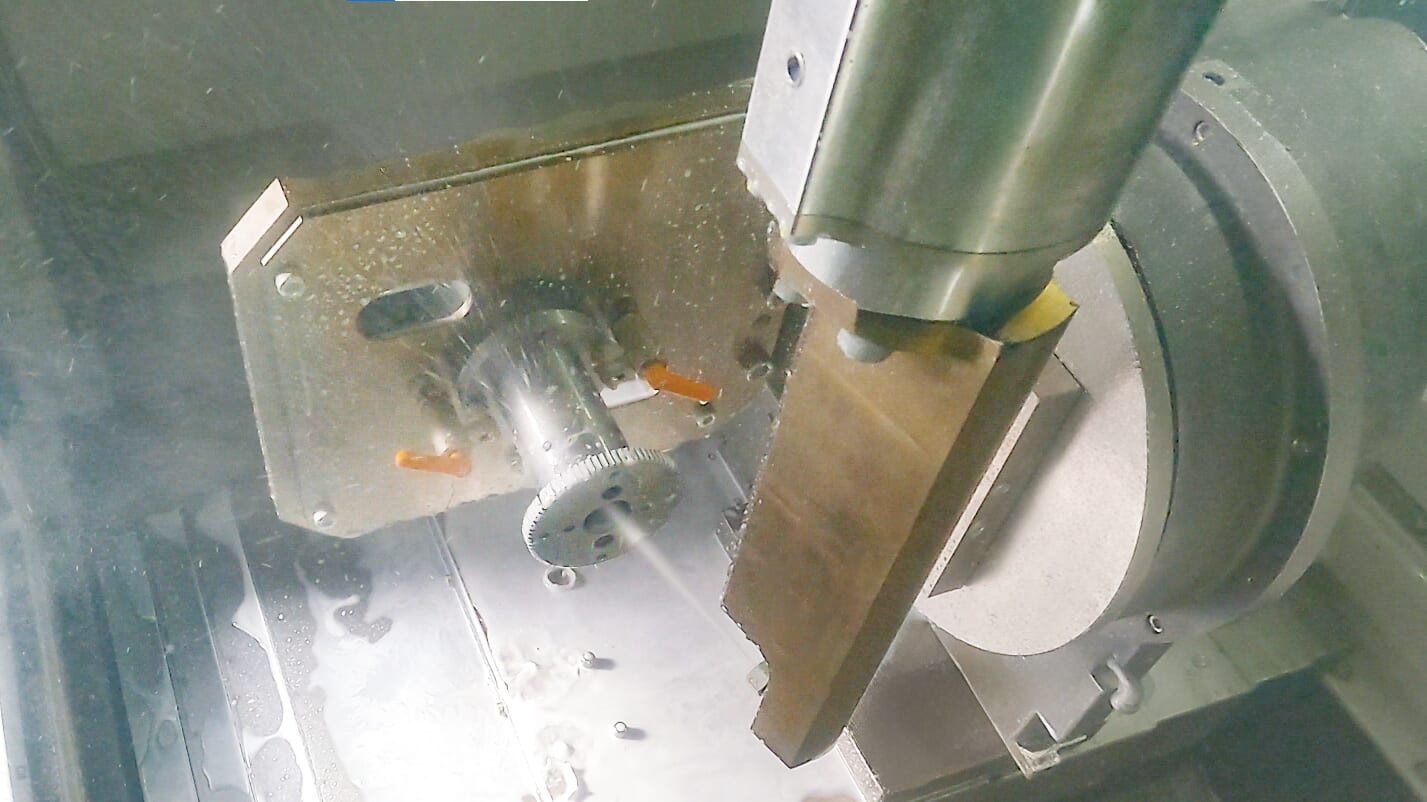

1 Targeted deburring with high-pressure water at up to 70MPa

While the conventional JCC 104 HYBRID deburred at up to 50 MPa, the JDM (Jet Deburring Machine) increases pressure by 40% to a maximum of 70 MPa. The increased pressure improves burr removal efficiency, supporting automation and labor reduction of manual deburring.

※What is water jet deburring?

Water jet deburring is a method that removes burrs using the impact force generated when high-pressure water (a water jet) ejected from a nozzle strikes the burrs.

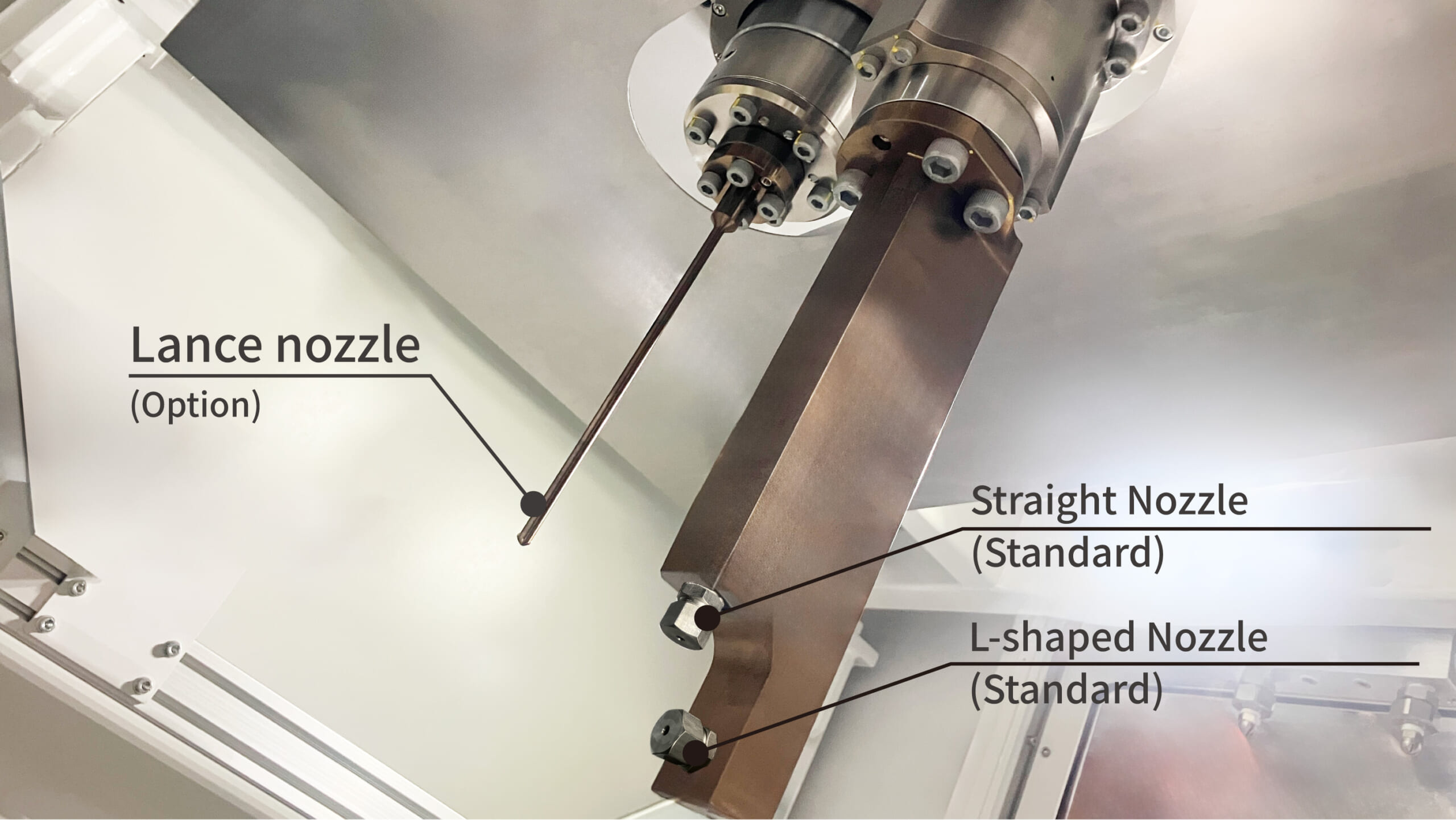

2 New Dual-Flow Nozzle reachs five sides of the workpiece.

The JDM’s new Dual-Flow Nozzle combines a straight and L-shaped nozzle into one, enabling burr removal on five surfaces of the workpiece with faster nozzle switching than a turret system, making it ideal for short-cycle deburring.

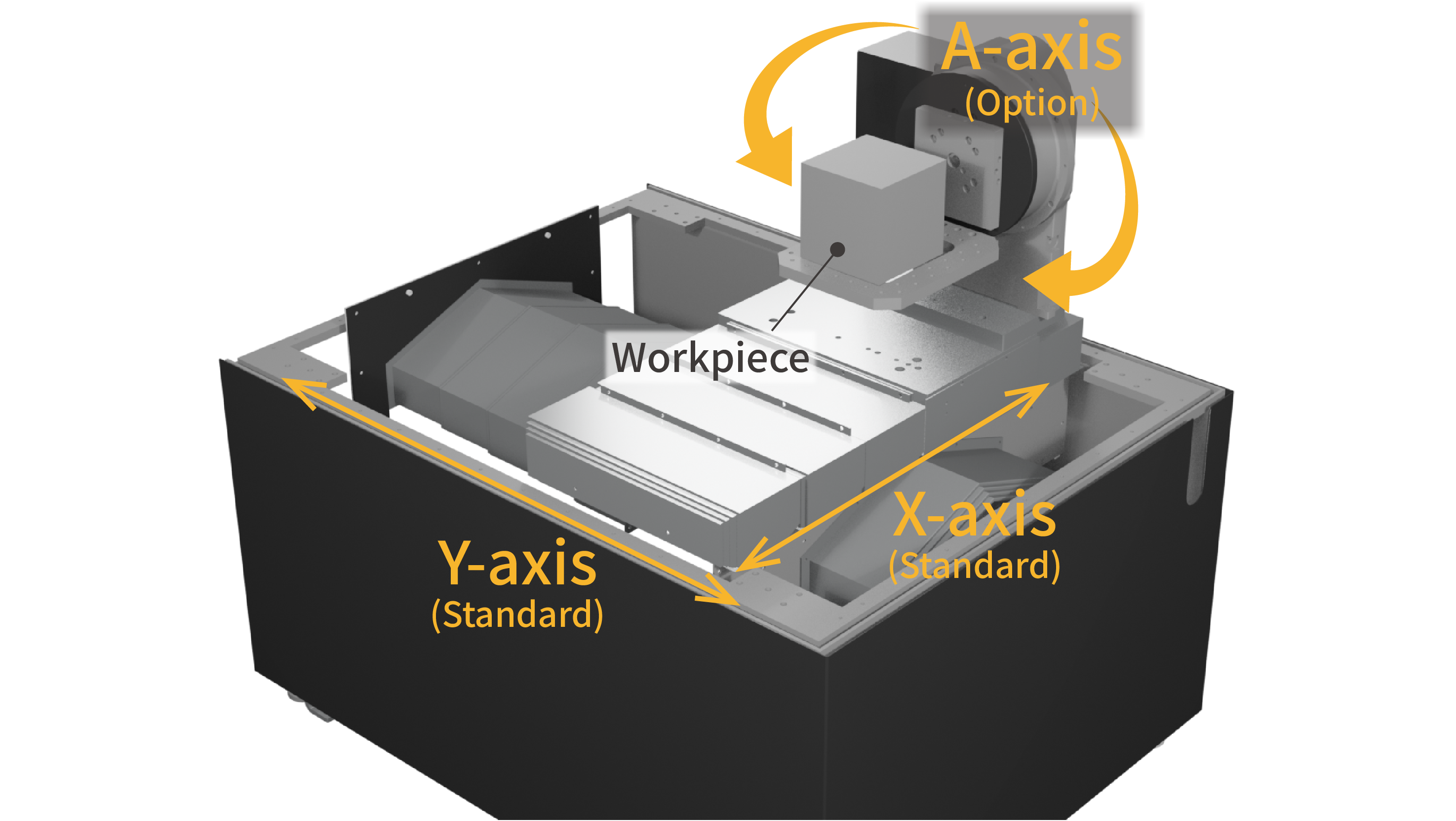

3 Equipped with an A-axis, allowing access to the back side of the workpiece!

With the table-mounted A-axis, the workpiece can be tilted for deburring and even the back side can be reached. Paired with Dual-Flow Nozzle, all surfaces of the workpiece are accessible.

4 Compact deburring machine, only 1,080 mm wide—automates burr removal in just a single-operator-sized space.

Designed with a compact 1080 mm width to fit easily into the area once used for manual deburring.

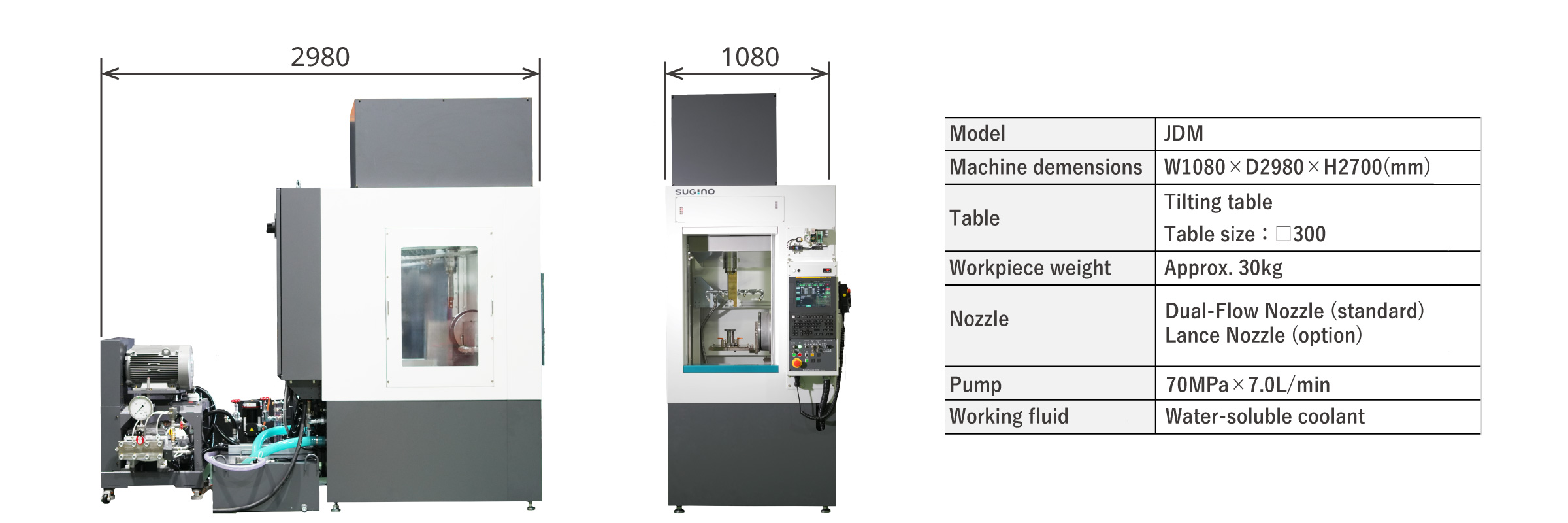

Specifications

Now accepting deburring tests

At Sugino’s “deburr labo”, we are always accepting deburring test requests from customers exploring robotic deburring automation. We don’t just perform deburring tests. First, we work with customers to understand their challenges and define clear goals. The tests are then conducted, and results are delivered in a detailed report.