VARIMOTOR : High-speed Spindle Motor

VARIMOTOR

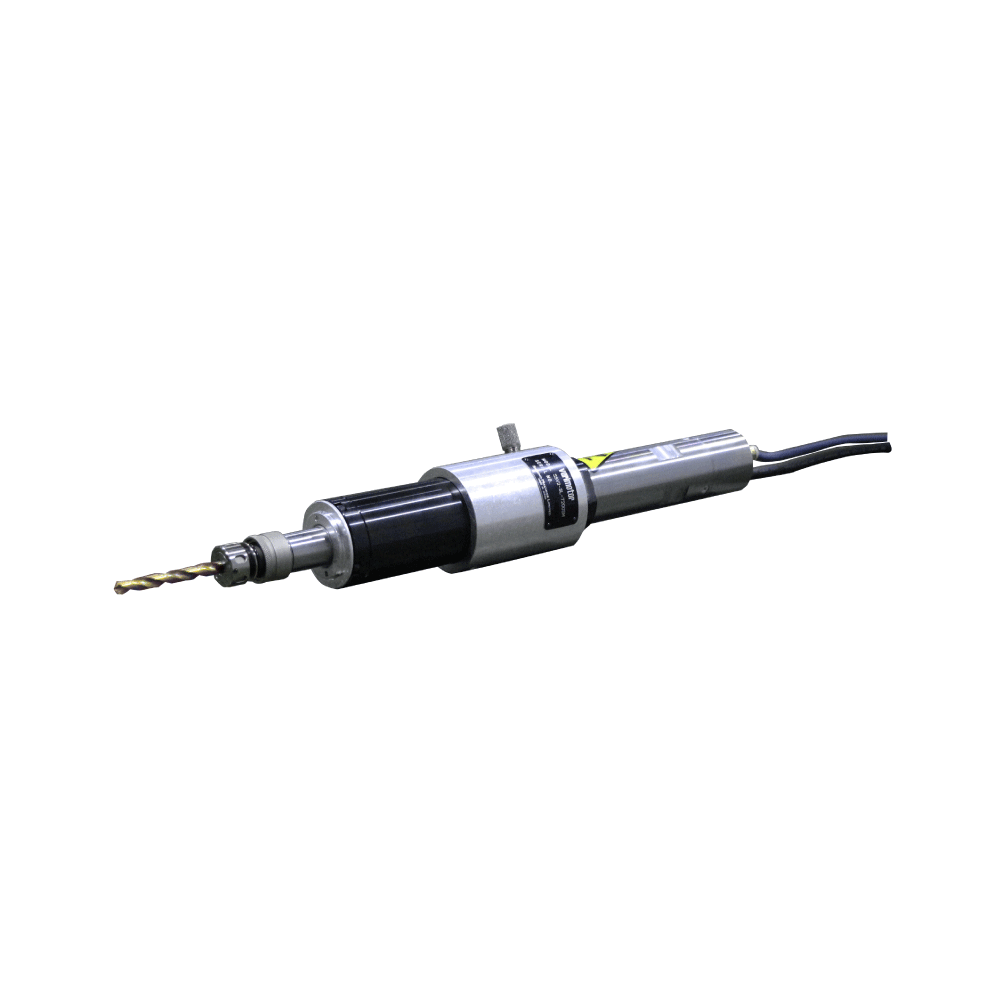

Compact spindle motor with a built-in high-precision, high-power DC brushless motor.

The “Varimotor” is a compact spindle motor with a built-in high-precision, high-power DC brushless motor. We have a line-up of three models that correspond to varying motor output. Direct-connection type and reduced-speed type specifications are available for each model.

Max. drilling size … φ3.5(Steel)/ φ5(Aluminum)

Features

High Precision and High Rigidity

This is a compact spindle motor with a built-in high-precision, high-power DC brushless motor. The unit comes with a precision angular bearing built into the main shaft and this allows the unit to perform deep-cut processing.

Dedicated High Performance

The rotation speed of the main shaft can be arbitrarily set by the inverter. High-level waterproof performance is obtained by combining air purge, via the motor cooling air, and labyrinth seals.

Application Examples

Work such as drilling and end milling is done in combination with a slide unit.

Deburring is done in combination with a robot.

Various types of cutting can be done by mounting the unit on special purpose machines.

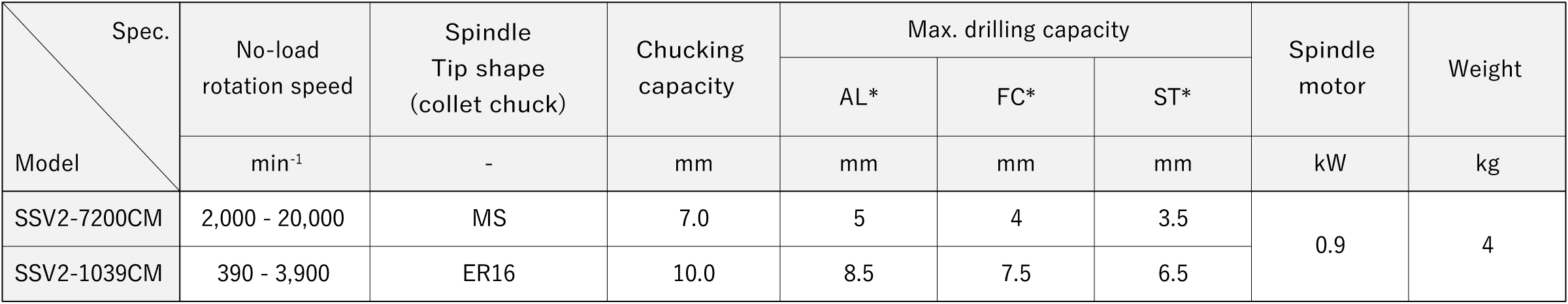

Specifications

Notes:

The selection of models should be based on the shape of the workpiece, material, cutting characteristics, diameter and material of tools, rotation speed (cutting speed), etc.

The drilling capacity displayed in the above table is based on values representing a drilling depth of two times the diameter of the drill.

Power-supply voltage is 3-phase AC200V±10%, 50/60 Hz.

To cool the built-in motor, please supply clean, dry air from the air supply aperture.

Make sure not to block air vents used for motor cooling with clamps, etc.

Furthermore, please make sure that the vents are always facing in the downward direction.Cable pull-out direction differs depending on the the model number.

For more information, please contact your nearest sales office.AL : Aluminum(ADC12) , FC : Cast iron(FC200) , ST : Steel(S45C)

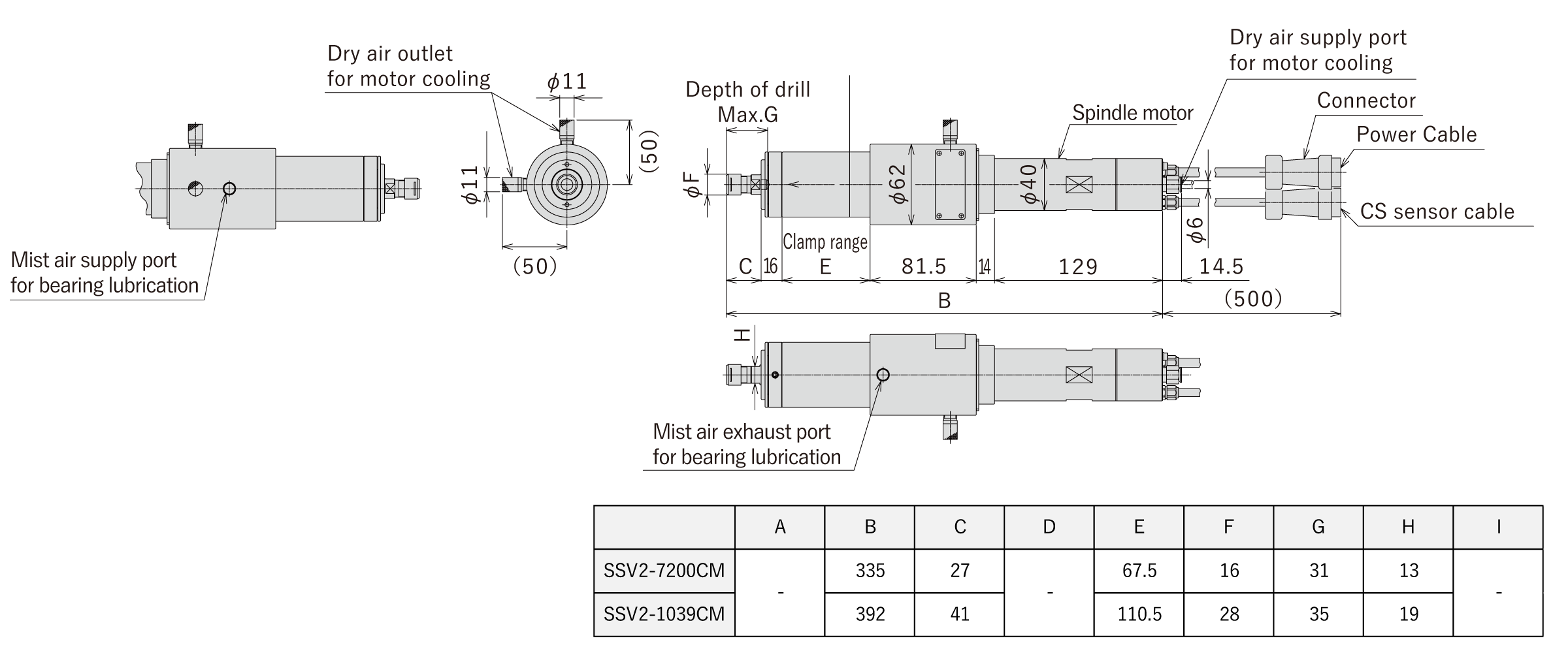

Dimensions