Achieves dispersion, emulsification, pulverization, and exfoliation of fine particles. | What is “STAR BURST”?

- Solves problems that occur when homogenizing particles

- What is dispersion, emulsification, pulverization, and exfoliation by the water jet method?

- Difference from other processing methods

- Characteristics of dispersion, emulsification, crushing, and cleavage by water jet method

- Applications/Industries

- Star Burst by Sugino Machine

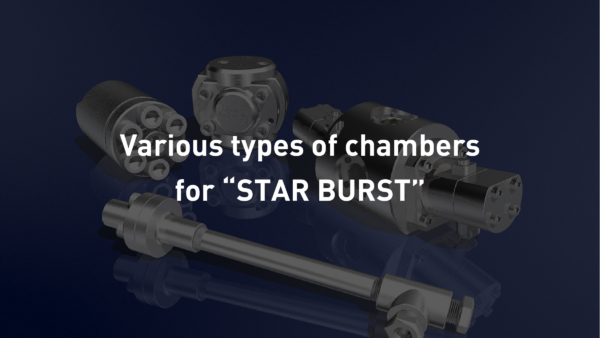

- Diverse Product Lineup from R&D to Production

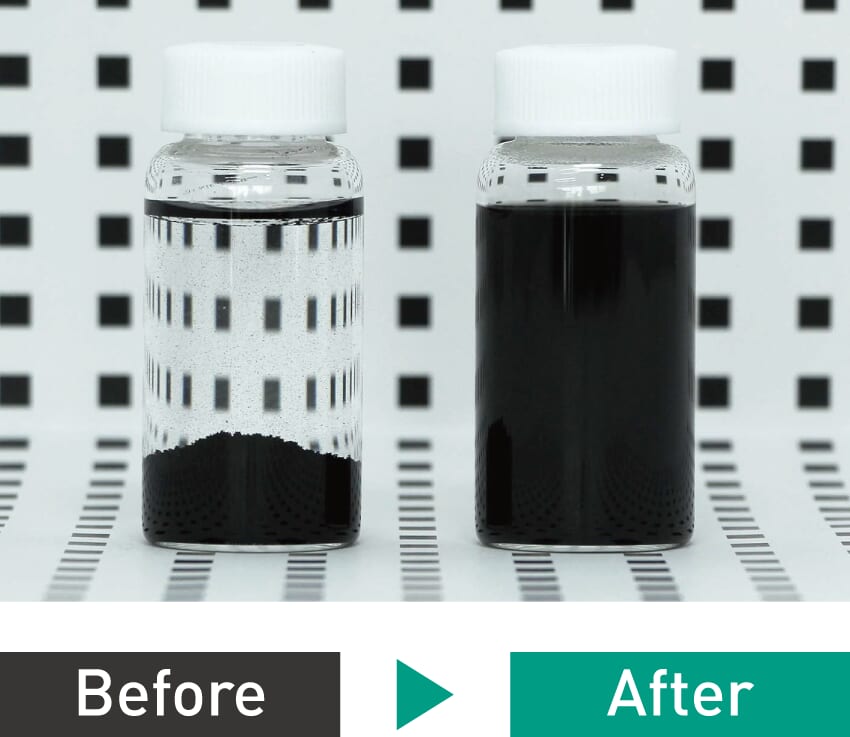

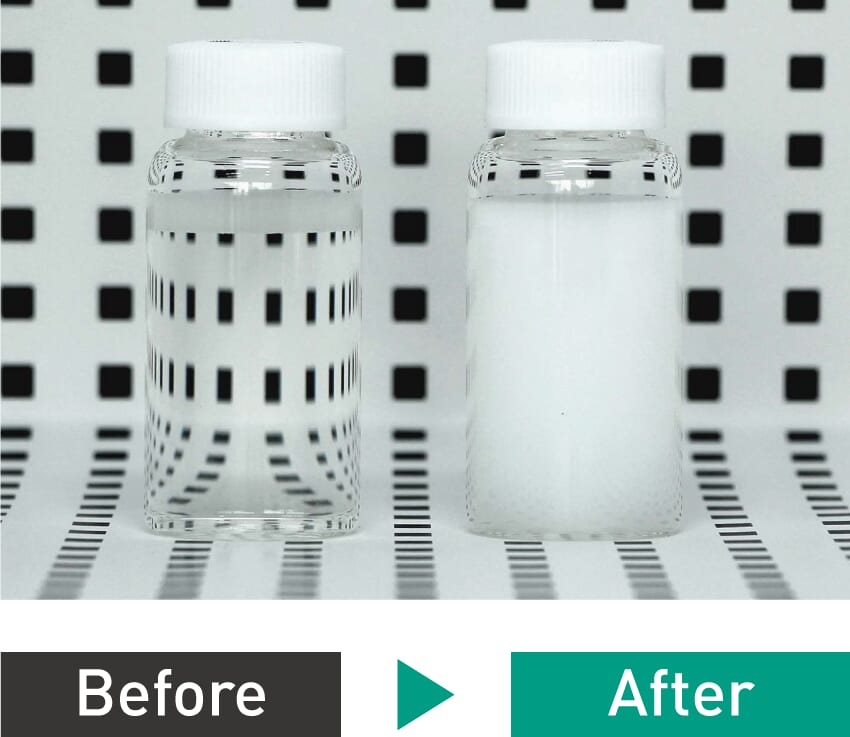

- Homogenization Examples

- Related Articles

- Related Product

Solves problems that occur when homogenizing particles

Processing or homogenizing of particles to nano level size can improve their efficacy. Homogenization of nanoparticles or ultrafine particles refer to the process of reducing the average diameter of a solid material’s particles.

For homogenization:

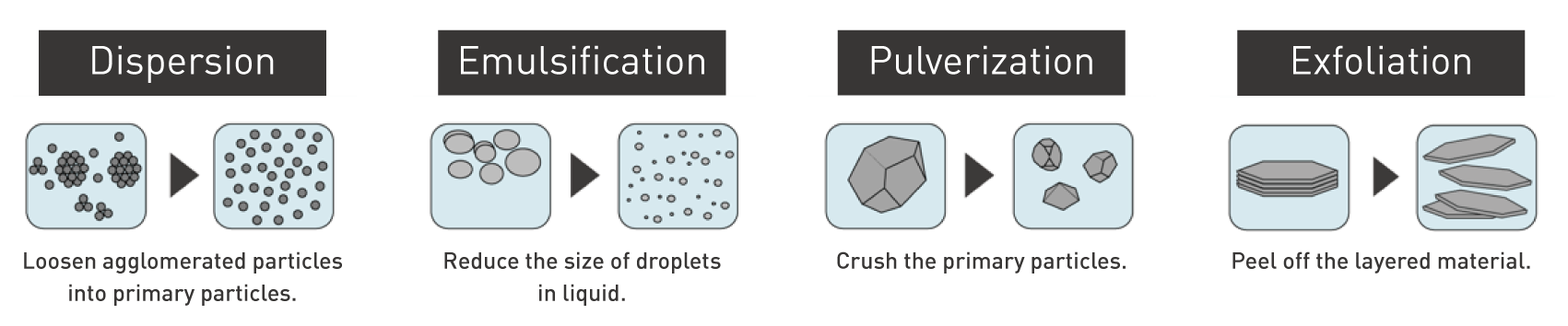

Dispersion loosens aggregated particles into primary particles, Emulsification reduces droplet size in a liquid, Pulverization refers to crushing primary particles, and Exfoliation peels layered substances while maintaining the aspect ratio – cleavage, etc.

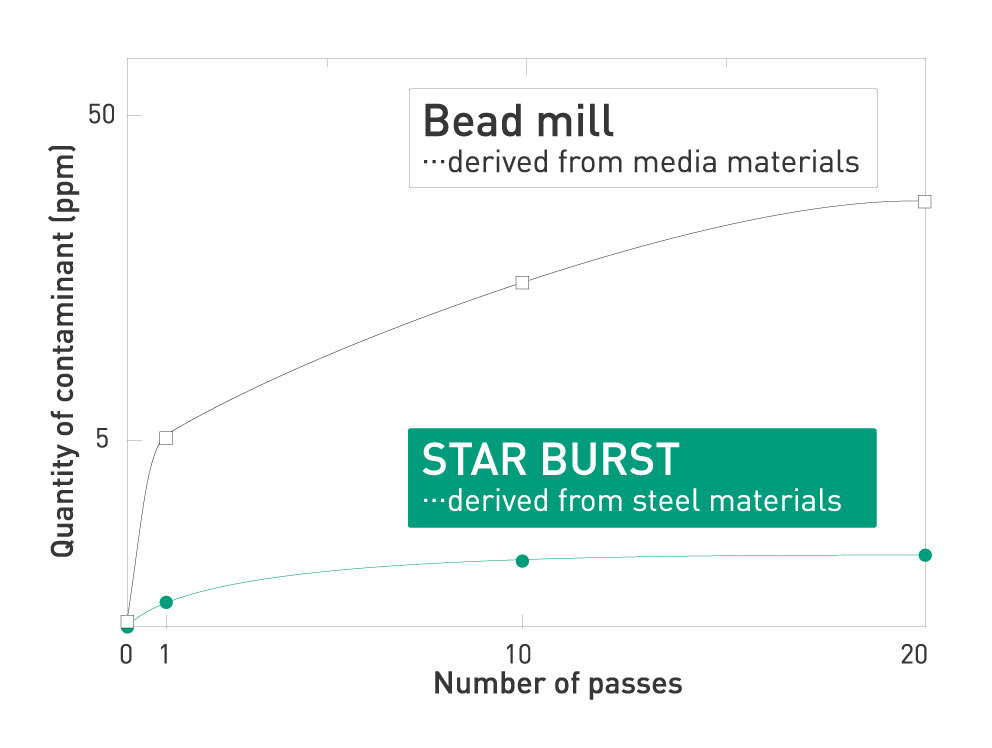

However, when milling with grinding media like a beads milling, there can be contamination problems (impurities).

Star Burst’s water-jet method solves these problems.

What is dispersion, emulsification, pulverization, and exfoliation by the water jet method?

What is a water jet?

High pressure water sprayed from a thin nozzle that exceeds the speed of sound.*

* Injection speed of 245MPa: Mach 2 (700m / s)

Powerful enough to cut iron, ideal for material processing.

Star Burst utilizes the power of water jet technology.

The raw material (slurry or emulsion) is jetted from the nozzle at high speed to make a water jet.

The strong shearing force applied during injection and the energy generated by collisions between raw materials atomize the raw materials to the nano level.

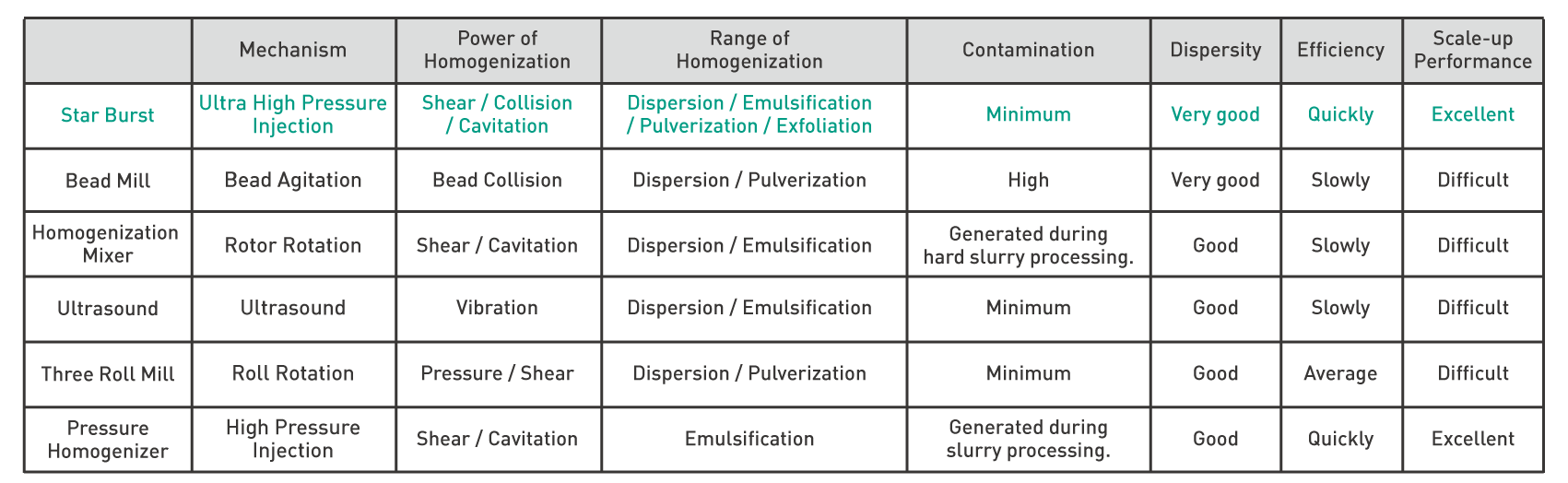

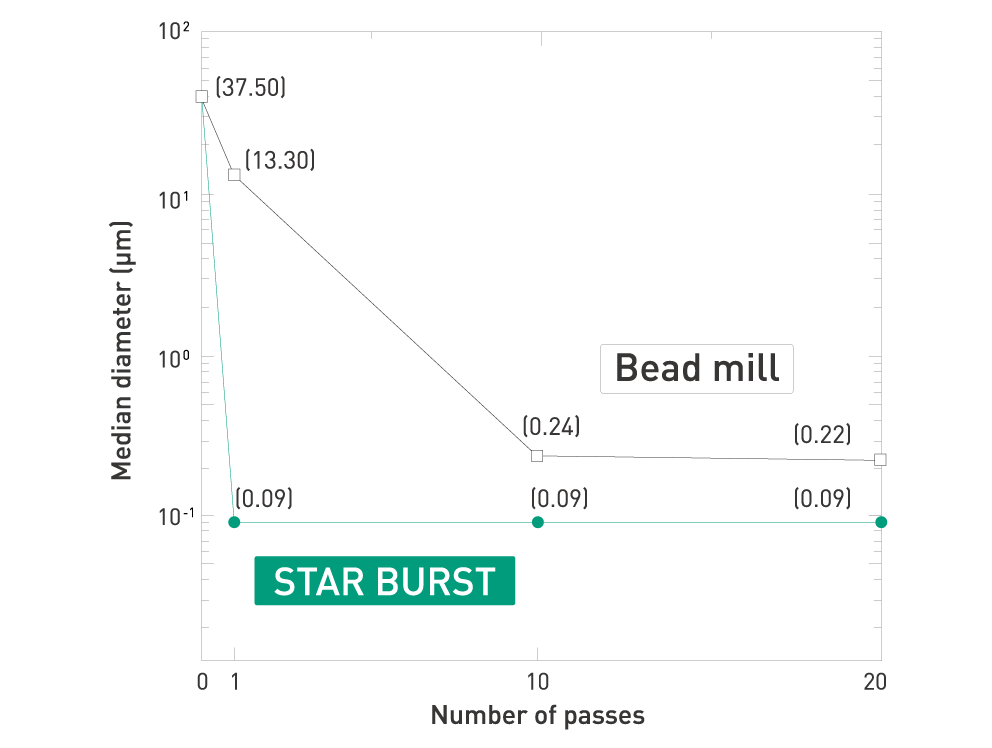

Difference from other processing methods

Characteristics of dispersion, emulsification, crushing, and cleavage by water jet method

Minimum Contamination

Star Burst does not use any grinding media and provides products with the minimum amount of contamination.

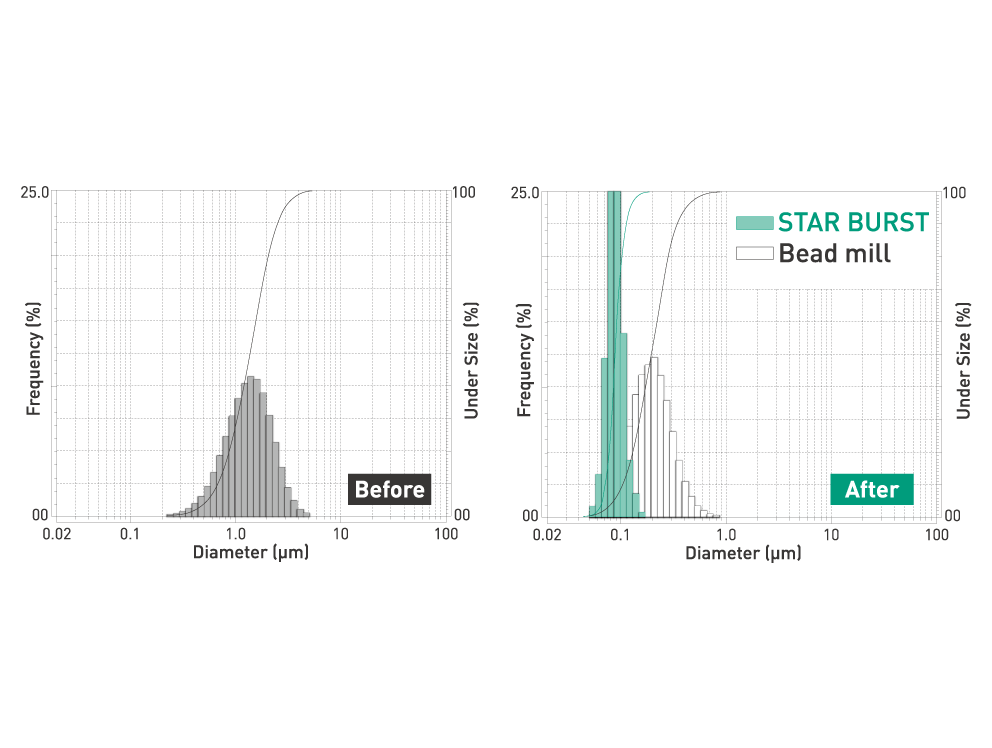

Homogenized Particle Size

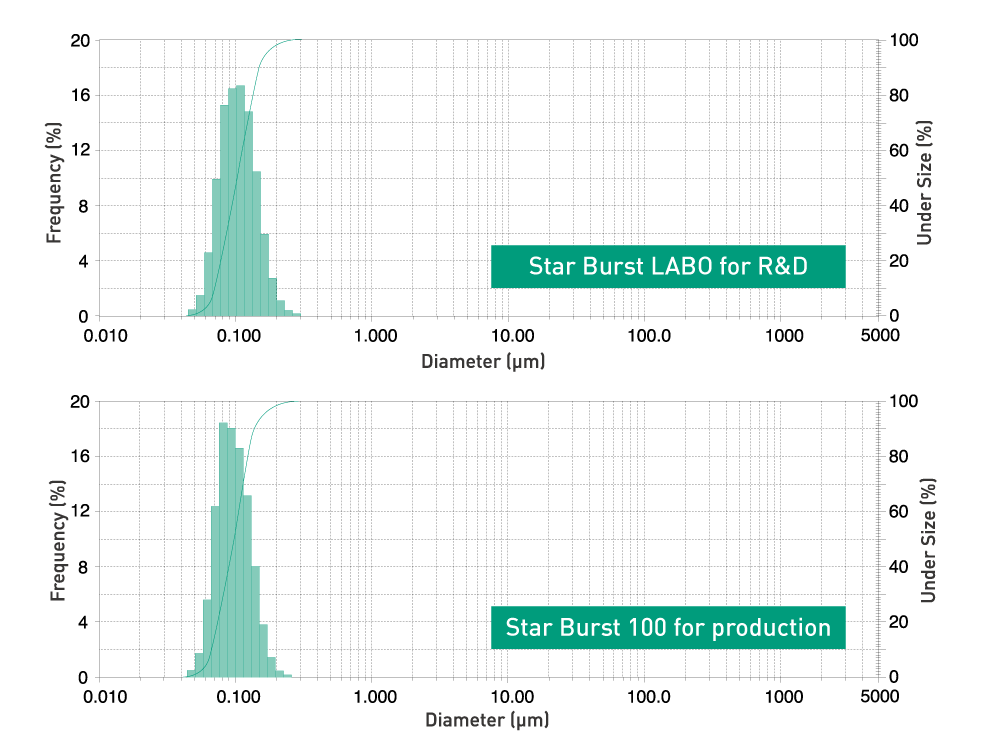

Uniform particle with narrow particle size distribution can be achieved by controlling the injection speed of raw material.

High Pulverizing Capability

Effective nano-level pulverization and dispersion can be achieved in a short duration of time.

Excellent Scale-up

Processing results achieved during research and development (R&D) are highly reproducible with our larger production-scale machines, making the transition to full scale production smooth and easy.

Applications/Industries

- Electronics(multilayer ceramic capacitors, battery materials, semiconductors)

- Pharmaceuticals

- Cosmetics

- Pigments (ink, paint)

- Chemicals

- Foods, etc.

Star Burst by Sugino Machine

Sugino Machine manufactures our high-pressure water jet equipment in-house.

Our wet atomization devices use water jet technology that is packed with capabilities, and backed by more than 70 years of experience and know-how.

Star Burst Mechanism/Circuit Diagram

Diverse Product Lineup from R&D to Production