CNCPRO: #25 Turret / Vertical Type Drilling and Tapping Machining Center

CNC PRO

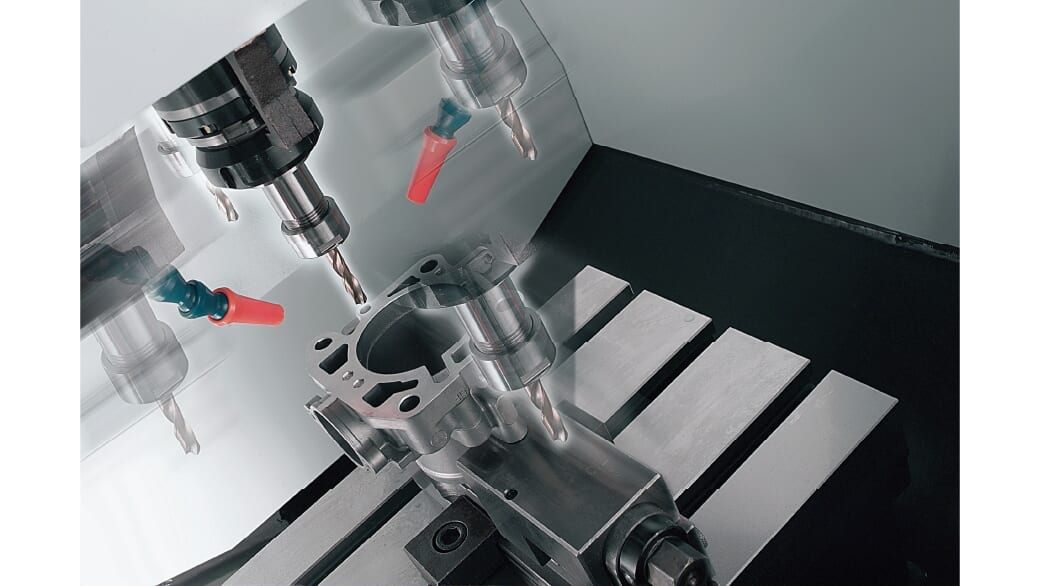

“CNCPRO” is a compact machining center that significantly reduces both start-up and operational costs by selecting only the functions required for drilling and tapping. An ideal machine for deburring.

Product introduction video

Advantages of the CNCPRO

Compact vertical design!

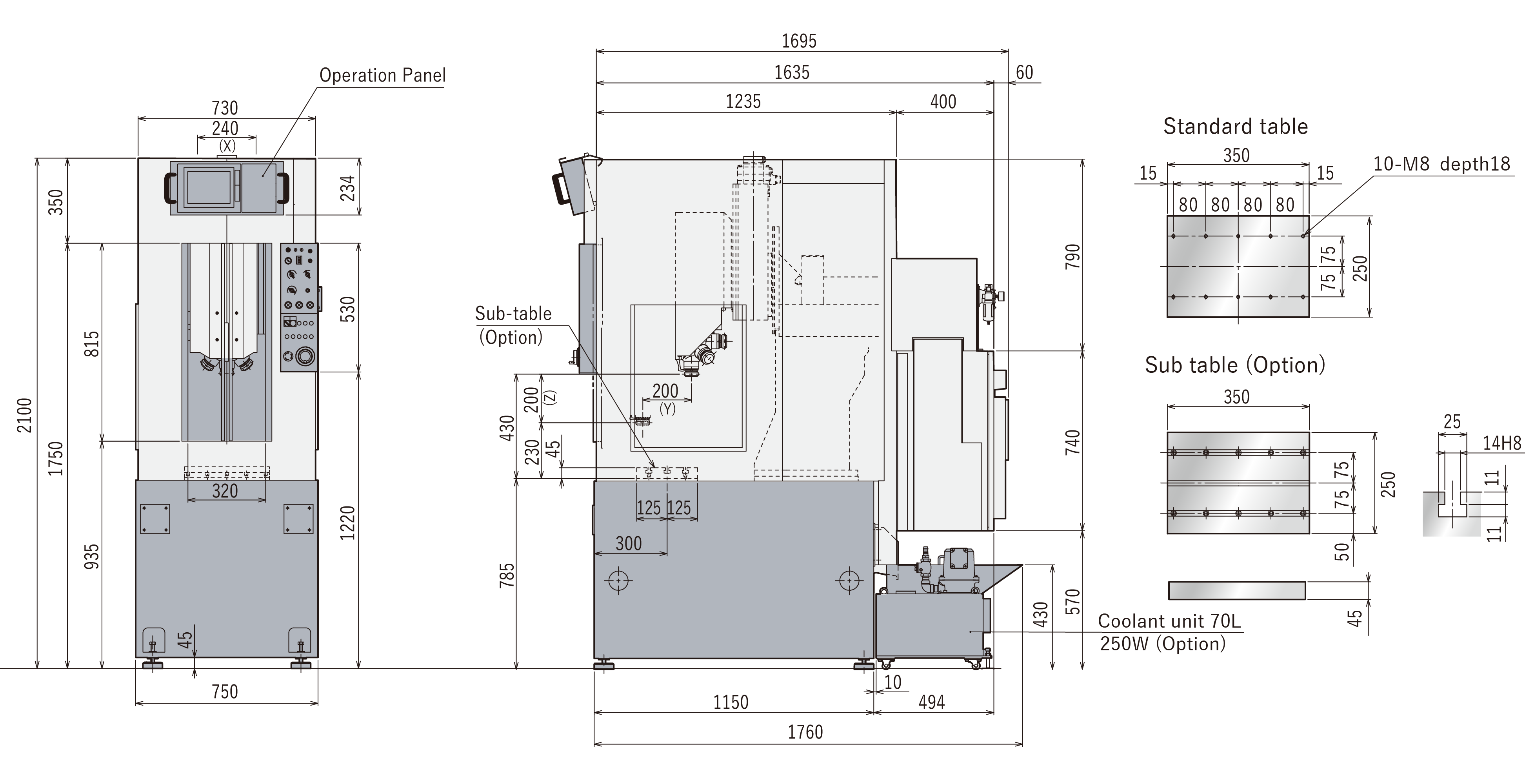

CNC has a compact design with a width of 750 mm and a length of 1,635 mm. The CNCPRO can be arranged in a tight configuration to reduce its footprint to half that of conventional machines. This enables effective use of available space.

High-speed and energy saving machining!

Achieved a tool-to-tool timing of 0.4 seconds and a chip-to-chip timing of 0.9 seconds by adopting the newly-developed taper clutch joint area between the turret head and the spindle. Furthermore, no hydraulic power is required to drive the machine, so energy costs are reduced dramatically.

Improved operability with a removable operating panel!

The removable operating panel can be attached to the upper part of the machine or kept close at hand. Designed for operability and efficient use of space.

Processing capacity

Drilling

- Aluminum 12 mm diameter

- Cast iron 10 mm diameter

- Steel 8 mm diameter

Tapping

- Aluminum M10 mm

- Cast iron M8 mm

- Carbon steel M6 mm

Specifications

| Standards | Long stroke | Auto workpiece changer |

||||||

|---|---|---|---|---|---|---|---|---|

| PRO-407 4-spindle type |

PRO-607 6-spindle type |

PRO-407L 4-spindle type |

PRO-607L 6-spindle type |

PRO-407A 4-spindle type |

PRO-607A 6-spindle type |

|||

| Stroke | X-axis | mm | 240 | 560 | 40 | |||

| Y-axis | mm | 200 | 150(200) | |||||

| Z-axis | mm | 200 | ||||||

| Table | Working area | mm | 350×250 | 600×250 | φ 600 | |||

| Distance from table surface to spindle nose |

mm | 230 – 430 | 170 – 370 | |||||

| Allowable load | kg | 150 AWC30×2 | ||||||

| Spindle | Standard | min-1 | 100 – 8,000 | |||||

| High speed | min-1 | 100 – 12,000 | ||||||

| Motor 10 min./continuous | kW | 0.75/0.4 | ||||||

| Feed | Rapid feed rate | m/min | 30 | |||||

| Cutting feed rate | mm/min | 10 – 12,000 | ||||||

| Min. programmable unit |

mm | 0.001 | ||||||

| Accuracy | Positioning | mm | 0.010 (in full travel), 0.015 (long stroke) | |||||

| Repeatability | mm | ±0.005 | ||||||

| Turret head | Number of spindles | No. | 4 | 6 | 4 | 6 | 4 | 6 |

| Index time | sec | 0.4 | ||||||

| Tool shank | – | BT25 Front clamp type | ||||||

| Max. tool weight | kg | 1.2 | ||||||

| Max. tool length |

mm | 160 | ||||||

| Chuck capacity |

mm | φ 0.5 – φ 13 | ||||||

| Index type | All cam index | |||||||

| Tool selection | Random, shortest approach | |||||||

| Power Sources | Power supply | kVA | 3 kVA AC 200V±10%, 50/60 Hz | |||||

| Machine | Width × Length × Height | mm | 750×1,635×2,100 | 1,100×1,635×2,100 | 750×1,844×2,100 | |||

| Weight | kg | 1,000 | 1,100 | 1,150 | ||||

Dimensions