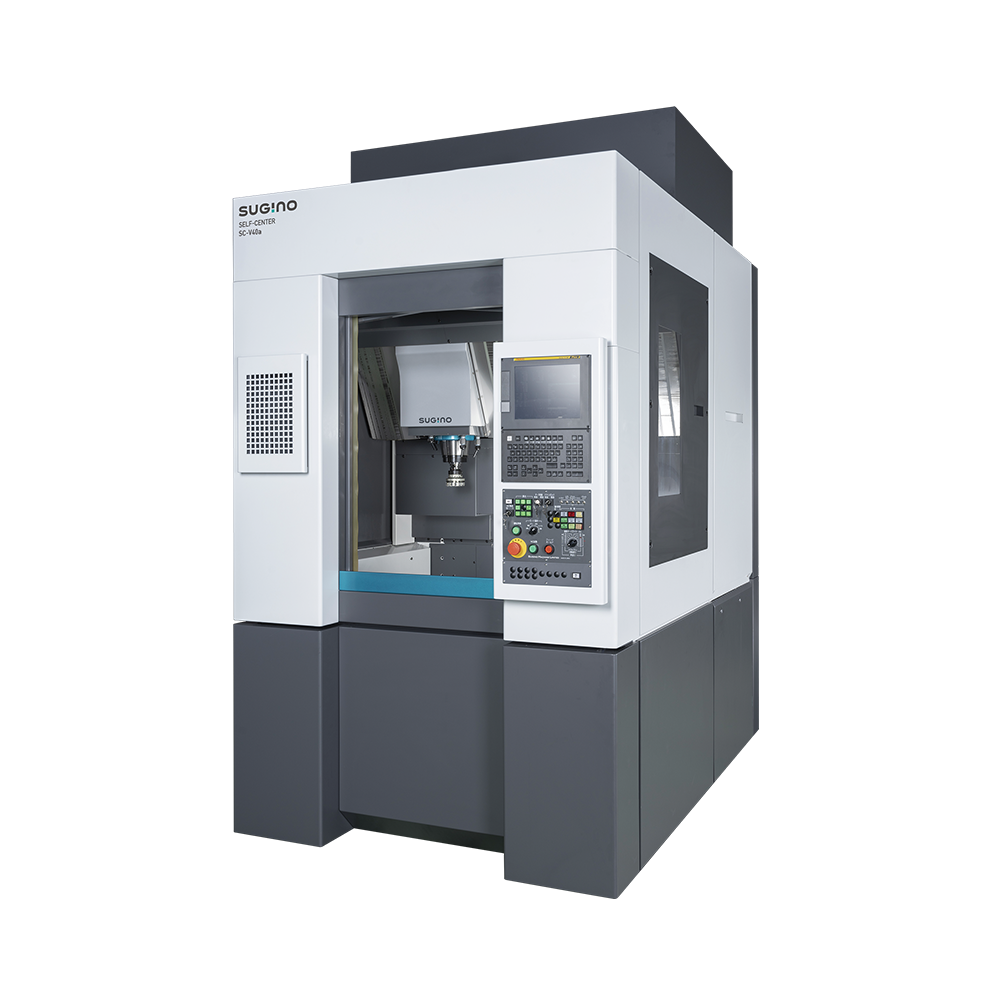

Self-Center SC-V30aG : #30 Vertical Grinding Center

SELF-CENTER SC-V30aG

It is a grinding center specialized in various ceramic grinding such as silicon, silicon carbde (SiC) , and quartz glass.

Features

1.Process integration

Capable of small diameter hole and outer diameter machining with a single chuck.

With a maximum spindle speed of 20,000 min-1 and a maximum C-axis rotary table speed of 200 min-1, this machine enables machining of small diameter holes and outer diameters on brittle materials with a single machine.

Reducing alignment and adjustment tasks leads to automation and stable quality.

1.Equipped with a workpiece measurement camera

The camera automatically reads marks and sets the workpiece coordinates.

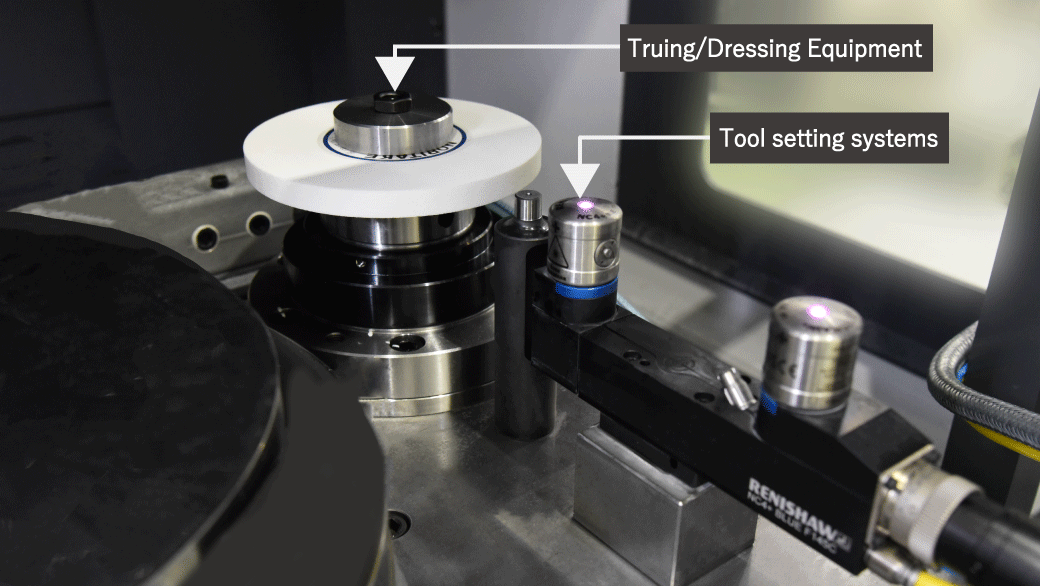

2.Equipped with tool measurement and dressing device

With the tool measurement system, it manages the wear of grinding wheels and enables automatic truing and dressing.”

3.Free from depending on individual skills by automation

Automating work coordinate setting and grinding wheel wear management moves away from manual tasks dependent on individual skills.

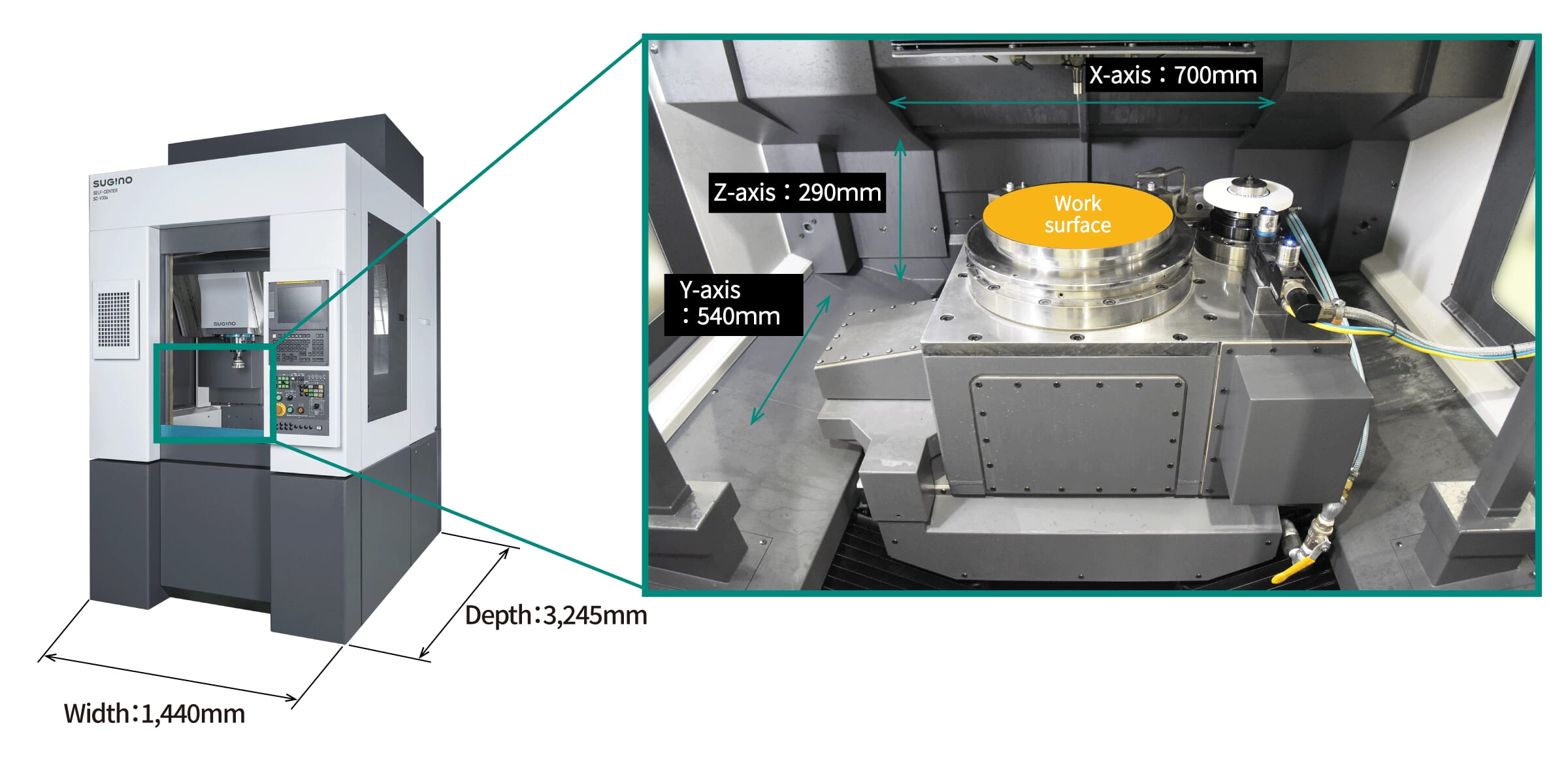

2.Space-saving

Achieving a large processing area while being a slim machine

The machine width is 1,440mm × depth 3,245mm, with a significantly wide stroke: X-axis 700mm, Y-axis 540mm, Z-axis 290mm, ensuring expansive travel relative to its width. Improving productivity per unit area.

3.High-precision support

High -precision specification with 8mm lead ball screw.

Switching the ball screw lead from 20mm to 8mm to achieve improved accuracy.

XYZ axis with scale feedback specification

Installing scale feedback devices to achieve high-precision positioning.

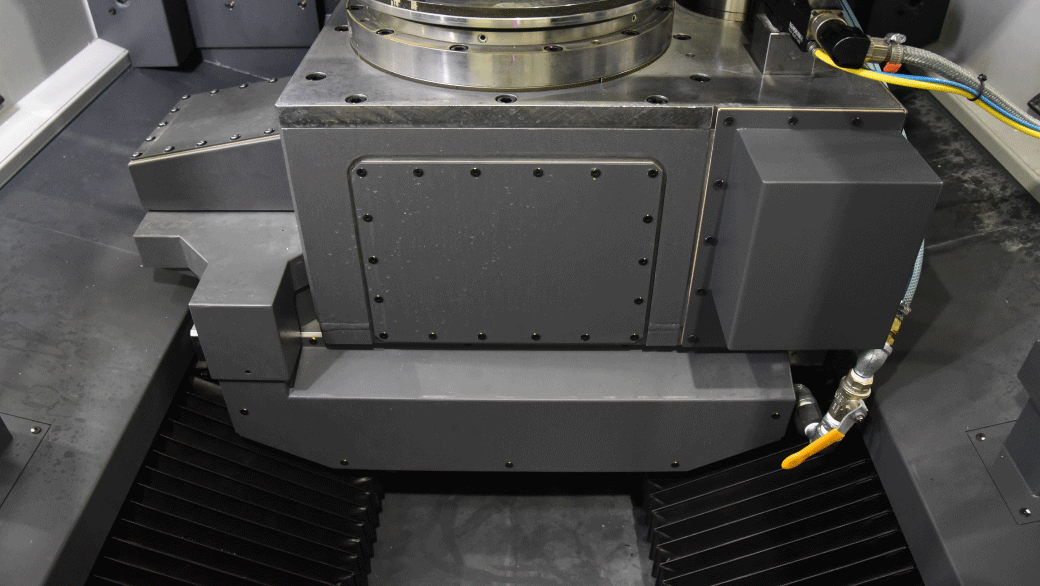

4.Thorough dust and rust prevention measures.

Bellows for Y and Z axes feature PVC-coating

Seamless PVC-coated fabric bellows are adopted.

Preventing sludge intrusion to protect LM guides and ball screws.

Surface treatment for ball screws and LM guides.

Performing reindent treatment on ball screws and LM guides to enhance corrosion resistance.

*Reindent treatment : Industrial black chrome plating

Electroplating technique for creating alloyed metallic surfaces.

Basic Specifications

| Tool shank | – | BBT30 |

|---|---|---|

| Number of tools | – | Max.31 |

| Max. tool dimensions | – | φ65 *If there are no adjacent tools, Max. φ100 |

| Stroke | mm | X:700 Y:540 Z:290 |

| Spindle rotation speed | min-1 | Max. 20000 |

| C-axis rotation speed | min-1 | Max. 200 |

| Repeatability | mm | ±0.001 |

| Rapid feed rate | m/min | X,Y,Z 24 |

| Machine dimensions | mm | W1,440×D3,245×H2,720 |

| Machine Weight | kg | 5,300 |

| Power capacity | kVA | 17 |

| CNC device | – | FANUC 32i-MODEL B Plus |