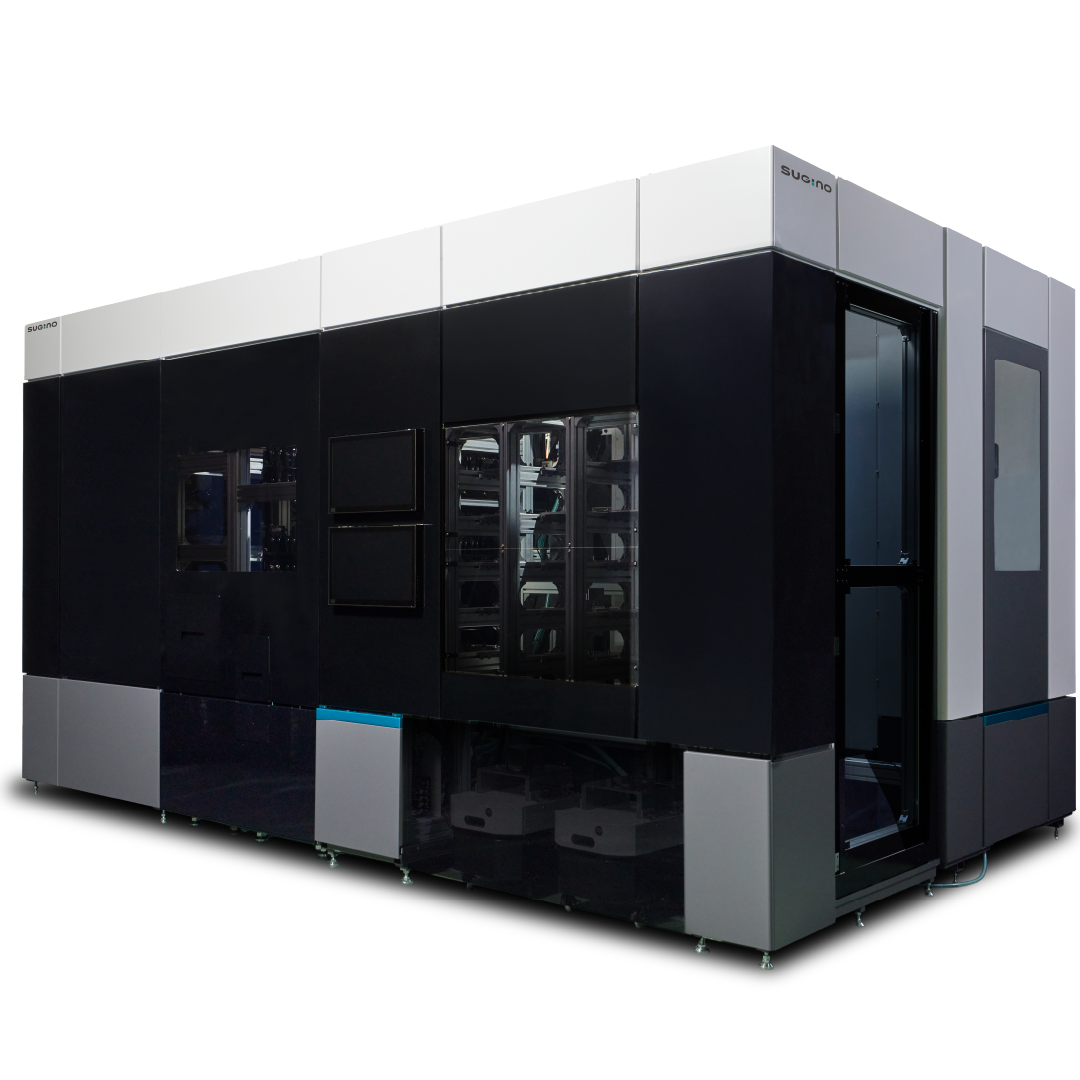

SMART M/C X10

SMART M/C X10

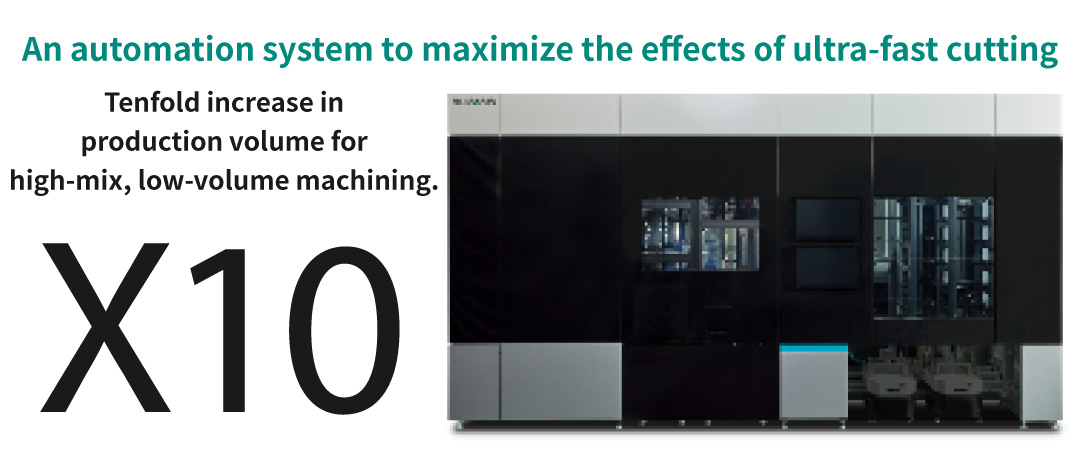

The X10 (X-Ten) is a next-generation machining system that boosts production volume tenfold in the machining of high-mix, low-volume parts.

Our machining center’s ultra-fast cutting technology, combined with a 100-tool magazine for extended unmanned operation, in-machine measurement and thermal displacement correction, and a work stocker & automated transfer system, enables automation of small-lot, multi-variety production.

Concept

Features

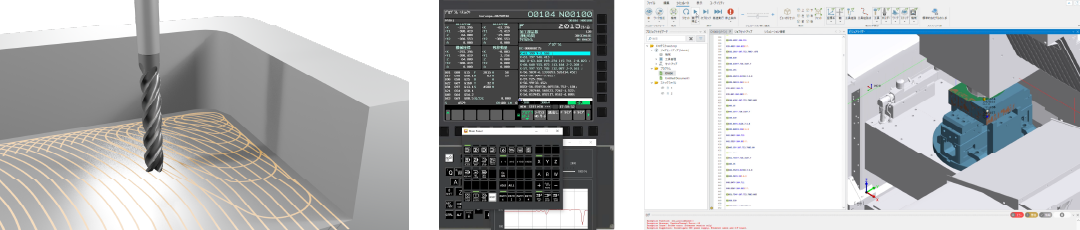

Ultra-fast cutting “Bakusoku Machining”

Acceleration of machining

The V40a, a 5-axis indexing machining center that excels in processing speed and rigidity for ferrous materials, and a load control machining program optimized for milling, significantly reduce the machining time for multi-surface workpieces.

Examples of ultra-fast cutting

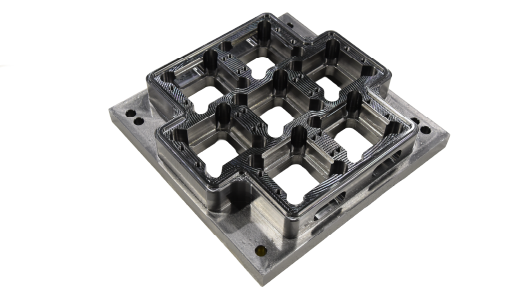

Parallel link

Material: S50C

Material dimensions: □150 × t70mm

Cycle time :35 min

Removal volume: 632cc/1 cycle [equivalent to 4.9kg]

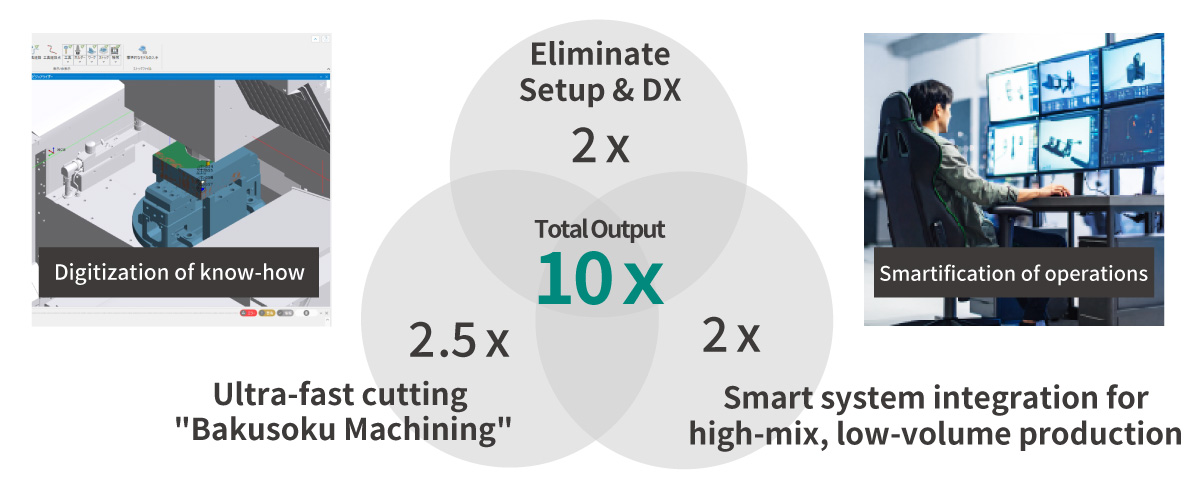

Inspection jig base

Material: S50C

Material dimensions: □250 × t52mm

Cycle time :170 min

Removal volume: 1,960cc/1 cycle [equivalent to 15.8kg]

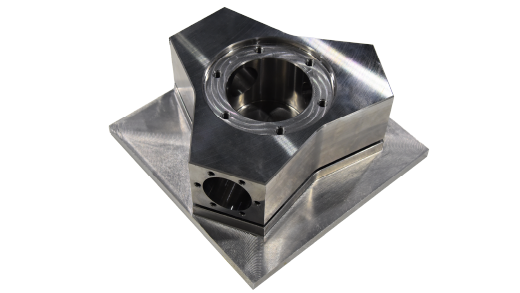

3-axis turret

Material: S50C

Material dimensions: □200 × t80mm

Cycle time :130 min

Removal volume: 2,000cc/1 cycle [equivalent to 16.1kg]

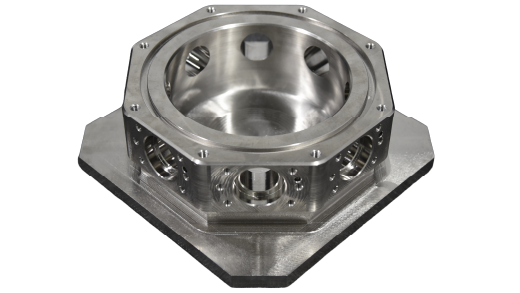

8-axis turret

Material: S50C

Material dimensions: □250 × t89.5mm

Cycle time :330 min

Removal volume: 3,570cc/1 cycle [equivalent to 28kg]

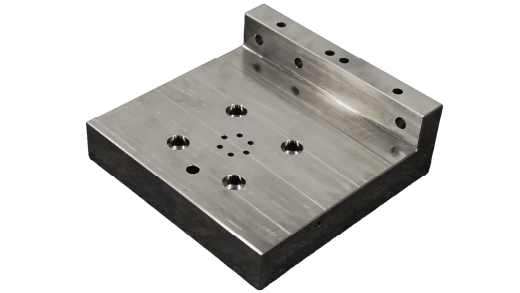

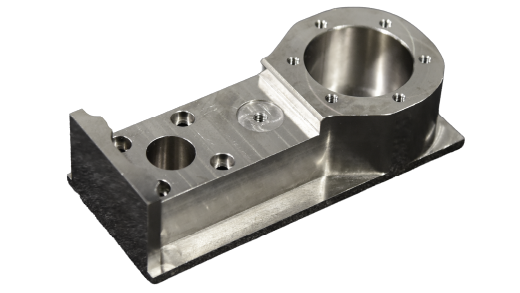

L-shaped bracket

Material: S50C

Material dimensions: □200 × t70mm

Cycle time :36 min

Removal volume: 1,540cc/1 cycle [equivalent to 12kg]

Nut holder

Material: S50C

Material dimensions: 155 × 68 × 41mm

Cycle time :20 min

Removal volume: 203cc/1 cycle [equivalent to 1.6kg]

Smart system integration

Realization of long-term unmanned operation

① 100-tool magazine

Safe continuous operation even at night

Capable of handling workpieces requiring numerous tools and multiple installations of the same tool. Reduces the number of tool changes, significantly saving effort and time.

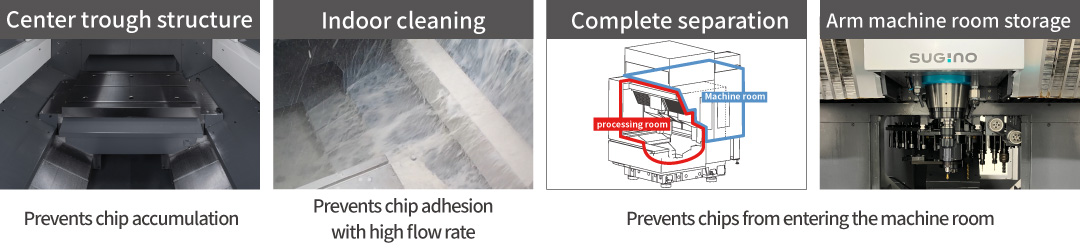

② Thorough chip control

Prevents machining quality issues and minor stoppages

Ensures reliable discharge and removal of chips.

③ Reliable quality assurance with in-machine measurement and thermal displacement correction

Prevents defects and enables unmanned operation

The spindle minimizes thermal displacement with cooling and real-time correction. Combines in-machine measurement with a touch probe and position detection with a linear scale to suppress thermal displacement of the feed axis.

④ Work stock & automatic transport system

Enables stable operation of high-mix, low-volume production

Work stock can be arranged up to a maximum of 25. Reduces the burden of setup changes with NC-controlled automatic transport by Cartesian robot.

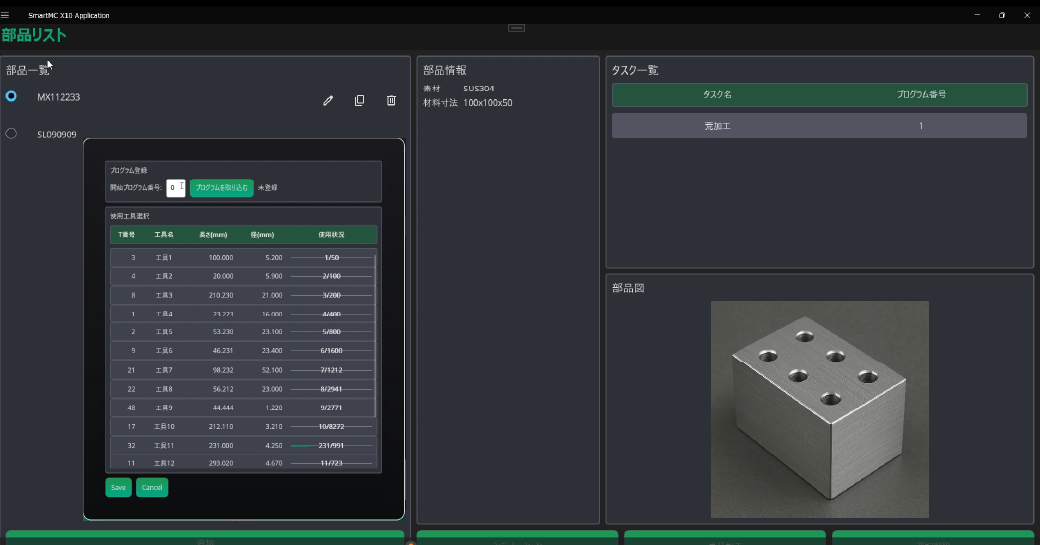

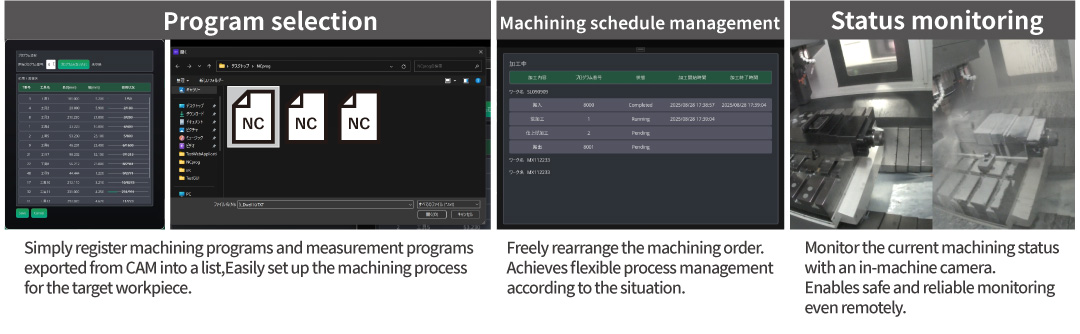

⑤ X10 process management software

Enables automation of high-mix, low-volume production

Visualizes the site from your desk PC

Easy operation: Intuitive UI that anyone can use quickly

Remote process management: Visualizes operating status in real-time

Complete at your desk PC: Eliminates the need for on-site verification

Visualizes the entire process from your desk PC without visiting the site.

Process management software supports an efficient production system.

Digitizing the skills of veterans

Peace of mind before machining. Optimize machining time and quality with CAM/SIM integration

“Ultra-fast cutting CAM recipe” that anyone can use

Utilizes the load control machining function of 3D-CAM to achieve high-speed, high-efficiency cutting beyond conventional methods. Original recipes (tool information and tool path settings) condensed with Sugino Machine’s unique know-how are pre-set, allowing easy program creation without specialized knowledge. Anyone can reproduce high-efficiency machining without relying on experience or skills.

Realizing a digital twin. Pre-verification and optimization with a simulator

The system incorporates an advanced simulator, allowing for accurate interference checks and calculation of machining time before processing. Integration with the CNC allows accurate determination of machining time based on the actual machine rather than just estimates, while the surface prediction function enables pre-assessment of the finished surface condition. This allows for pre-confirmation of machining accuracy and quality, significantly improving the accuracy of process planning and delivery estimates.

Bringing talent and technology into the future. Hands-on technology transfer and training service

The intuition and know-how cultivated by skilled workers will be lost if not passed on to the next generation. Hands-on service systematizes the tacit knowledge of veterans and reflects it in 3D-CAM and simulators. Transforms it into a “digital asset” that can be shared by the entire team. This eliminates the risks of labor shortages and skill transfer, allowing for the confident introduction of X10. Builds a technological foundation as an investment in the future through a one-month practical training curriculum.

| Support items | Support contents |

| CAM dedicated to ultra-fast cutting | CAM introduction training Ultra-fast recipe, customer-arranged recipe training Linguistic and digital conversion of customer know-how In-machine measurement program creation training |

| High-performance simulator | High-precision simulator operation training Machining surface estimation function operation training |

| X10 process management software | Part number management, program management, tool management Machining schedule management |

| X10 equipment | Installation, adjustment, operation adjustment Machining startup training |