BARRIQUAN BRQ-TX01: Automate your deburring operation / Floating tool holder

BARRIQUAN BRQ-TX01

Floating function of BARRIQUAN solves all problems in deburring automation.

Floating function of BARRIQUAN solves all problems in deburring automation.

Typical deburring problems with a CNC Machine

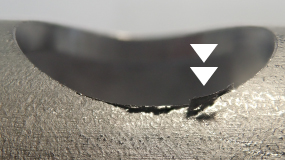

Remaining Burr

Cutting Too Deep

Complicated Workpiece Shape

Functions of BRQ-TX01

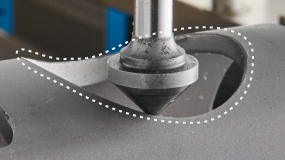

Floating Function

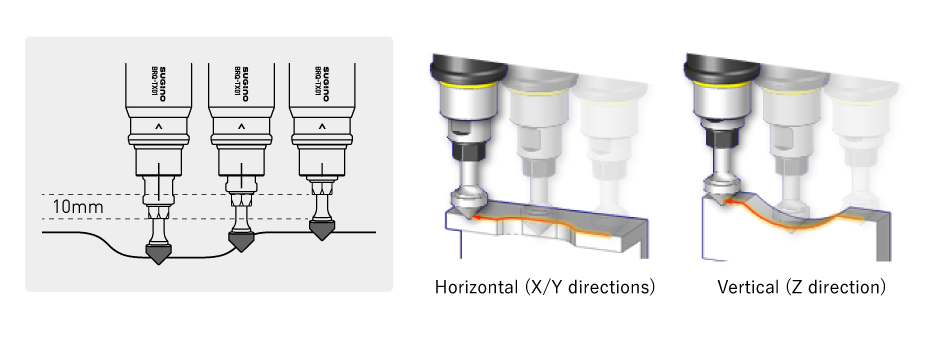

BRQ-TX01 is a tool holder with built-in floating function.

The floating function (float amount max. 10 mm) enables the deburring cutter to follow complicated workpiece shapes, and thus prevents the remaining burrs or too deep cuts on the workpiece.

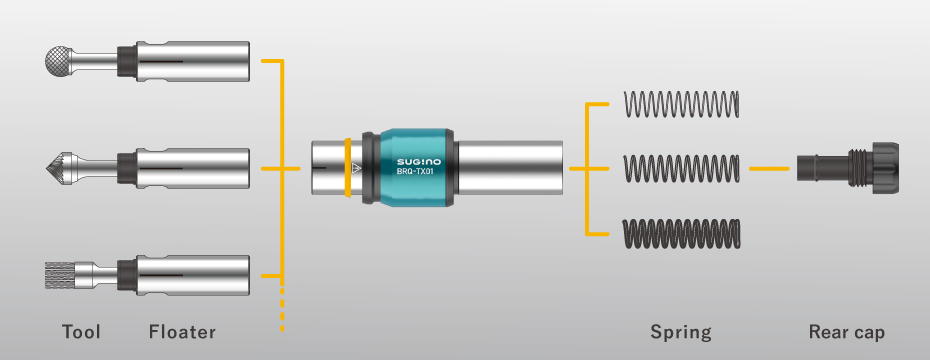

Quick Disconnect

While you are trying to find the best condition for deburring, you may need to change cutting condition so frequently.

New Barriquan BRQ-TX01 enables quick disconnect of floater as well as springs. No tool is required, you can change tools and springs manually.

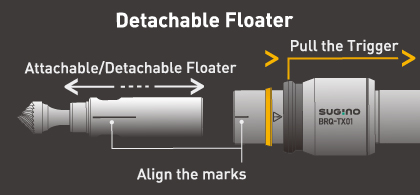

Change Floater in 3 seconds [new!]

You can pull trigger and change floater in 3 seconds.

No need to waste your time for tool change.

Easy maintenance

No tool is required for daily maintenance.

Daily maintenance will extend lifetime of BARRIQUAN.

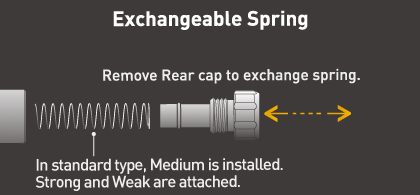

Spring change manually (no tool required) [new!]

You can detach rear cap manually (no tool is required).

Please choose best spring to adjust cutting amount.

(Although you can detach a rear cap manually, it cannot be loosened while Barriquan is rotating at high speed in machine spindle.)

How to replace the spring

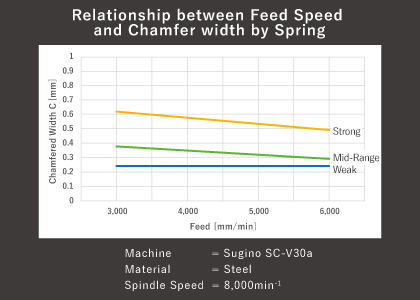

Performance of BRQ-TX01

Can work with high spindle speed up to 12000 min-1

Shorten Cycle Time with High Spindle Speed & High Feed

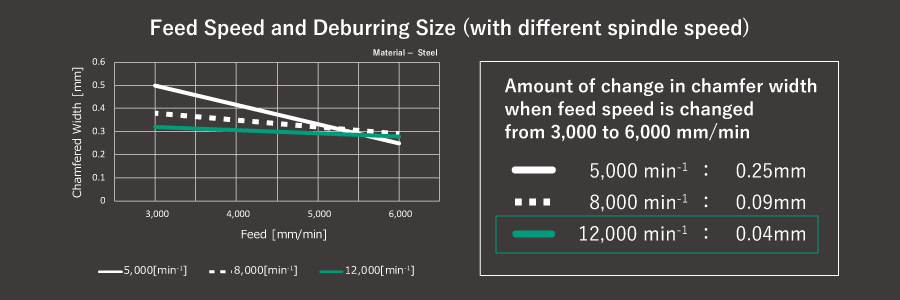

The guideline ratio of spindle speed (rpm) and feed rate (mm/min) is approx. 1 : 0.3 – 0.6.

Higher spindle speed enables higher feed speed.

Also, with higher spindle speed, we can obtain smaller deburring cut.

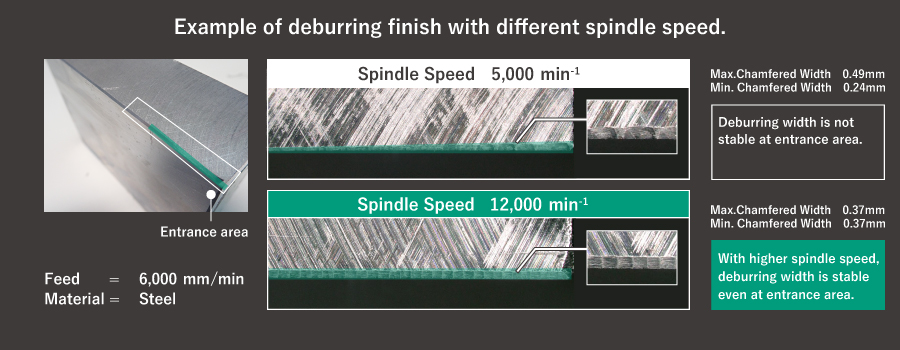

Stable cut at the entrance of the workpiece.

Although the entrance area is one of the most difficult areas with float deburring, you can obtain stable deburring surface with high spindle speed.

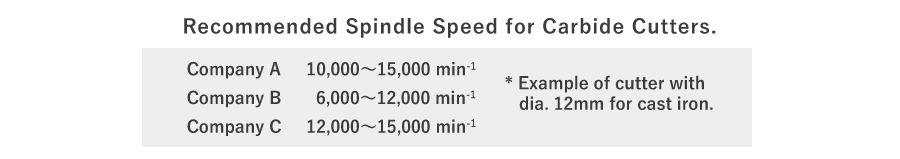

BRQ-TX01 works with recommended conditions of carbide cutters.

Generally, the required spindle speed for carbide cutters used for deburring are 10000 to 15000 min-1.

With BRQ-TX01, you can use carbide cutters under their required spindle speed, which will extend their lifetime.

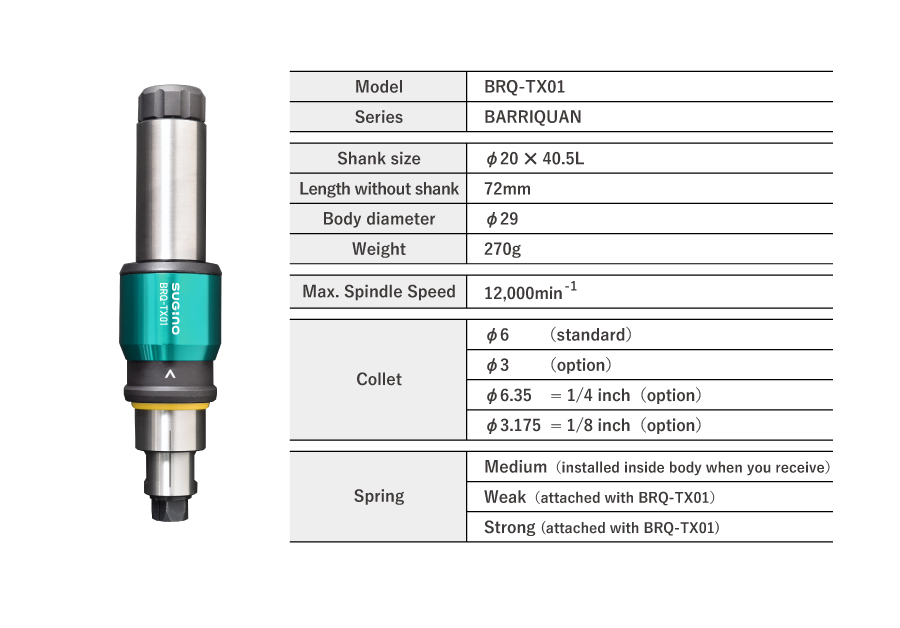

Specifications of BRQ-TX01