Roller Burnishing Tool SUPEROLL SES-AH [Spherical surface]

SUPEROLL SES-AH

MULTI ROLLER type

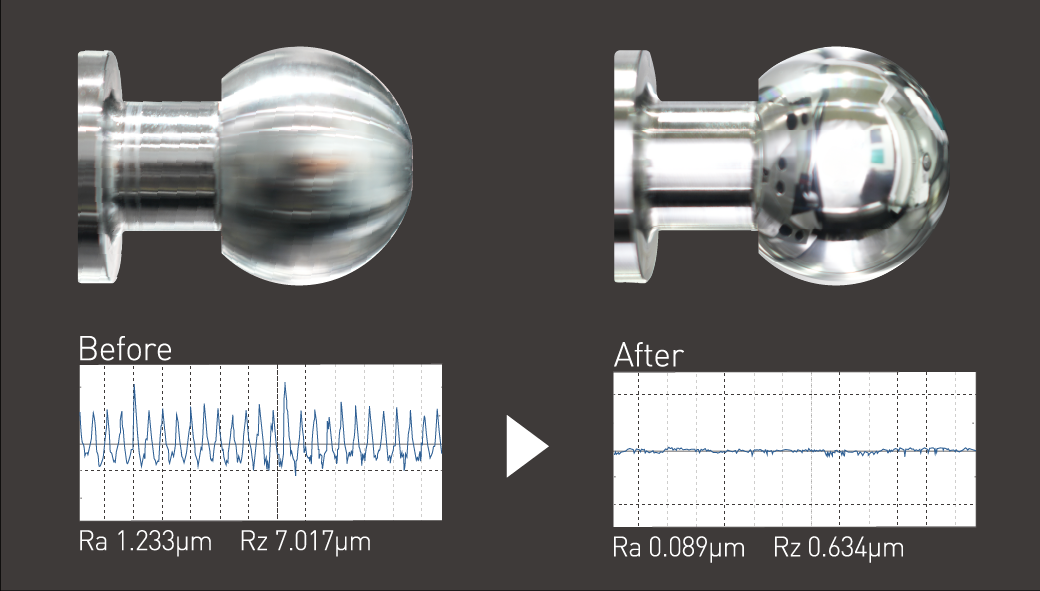

This is a roller burnishing tool designed for mirror finishing (surface modification) of spherical workpieces such as ball studs and tie rods.

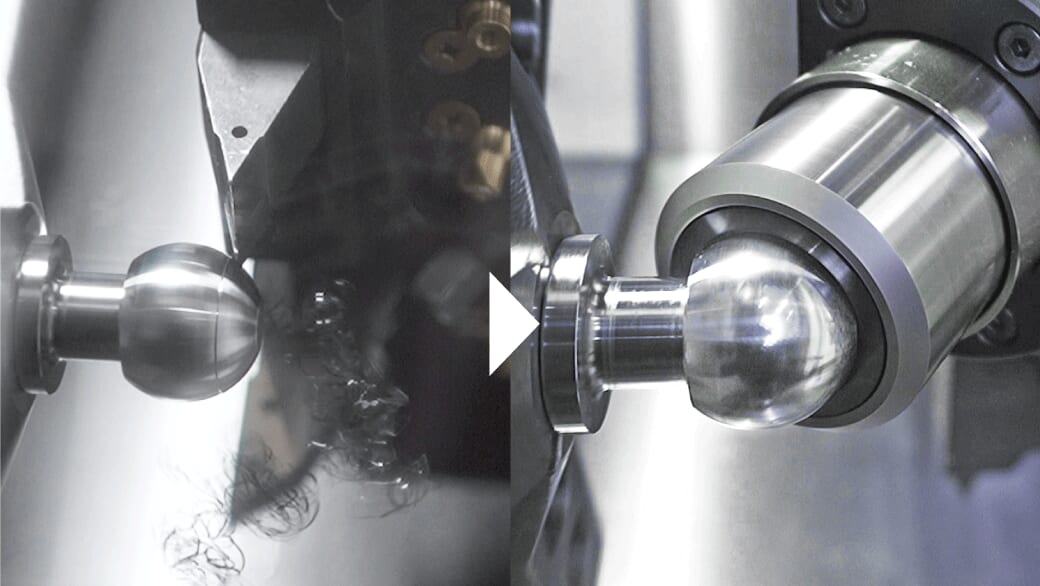

It can be used on a standard NC lathe with milling function.

Video

Features

High speed & high quality finishing

With its multi-roller structure, mirror finishes of Rz 0.8 μm or less can be achieved in 3–6 seconds.

Single-chuck machining on a standard NC lathe.

No dedicated equipment required.

Spherical finishing can be achieved simply by mounting it on a standard NC lathe with milling function.

Product Information

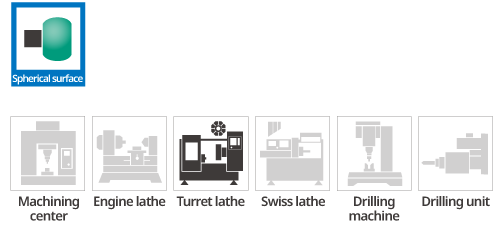

Supported workpiece shapes: Spherical surface

Attachable driving units: Standard NC lathe with milling function

Specifications: W 200 × D 95 × H 153 mm, Weight 6.5 kg

Ball diameter: approx.Sφ10~Sφ40

※ Other sizes are also available.

Interference or unprocessed areas may occur depending on the neck or tip shape of the workpiece.

For more details, please contact us.

For tool selection

You need to prepare a tool suitable for the spherical shape to be processed.

If the ball diameter changes, the processing diameter can be adjusted by changing the head.

For more details, please contact us.

Conventional SES: Product Information

Attachable driving units: Engine lathe

Both the workpiece and the tool need to rotate, and a dedicated tool holder may be required.

Ball diameter: Sφ10~Sφ30

What is “SUPEROLL” processing?

For more details on Superoll processing, please see here.